Technology

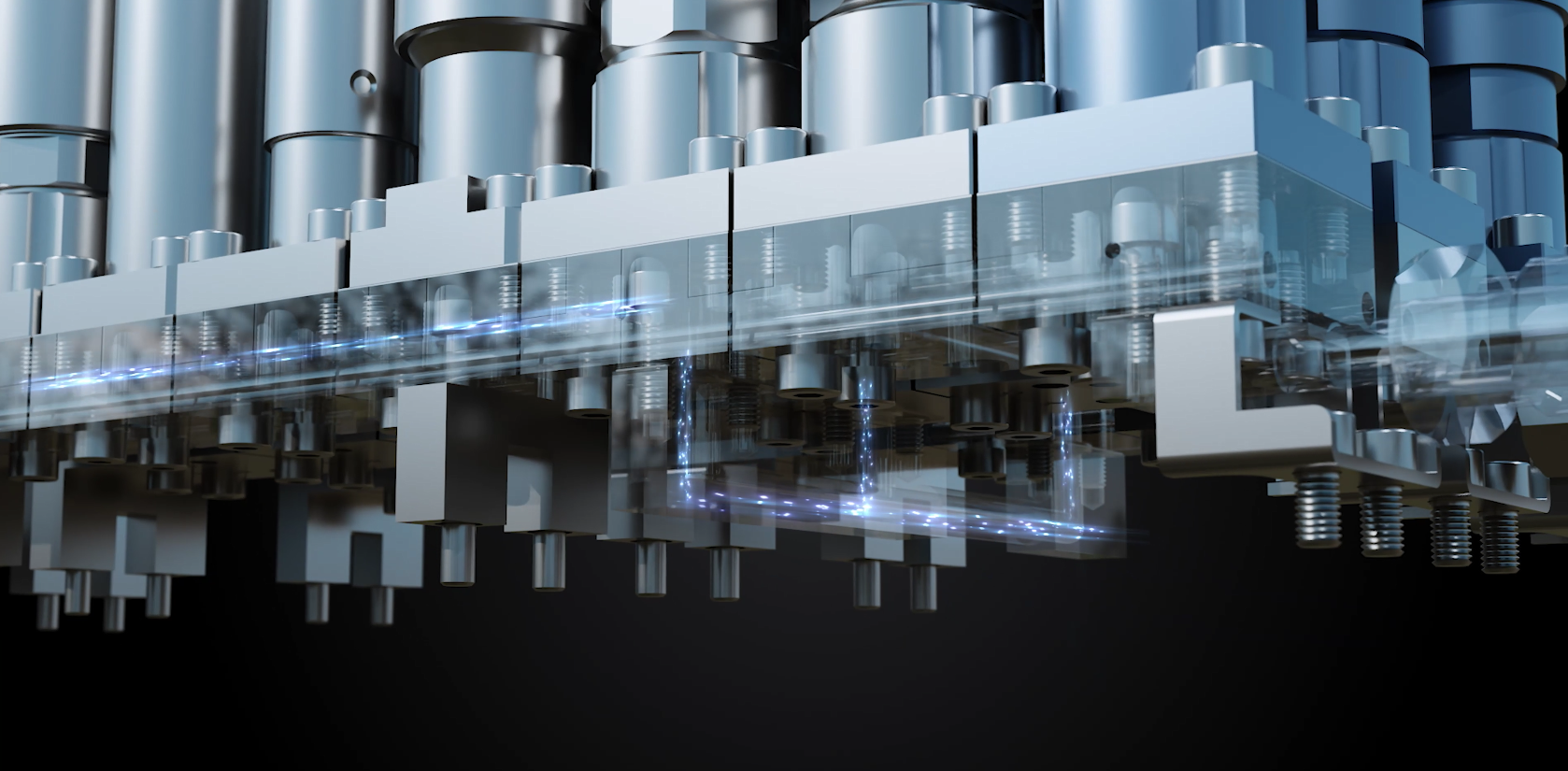

Stainless Steel Ultra-High Surface Finish Stainless Steel Manufacturing Technology

Employing self-designed tooling in conjunction with precision machining technology such as drilling, milling, and reaming, this technology achieves the stringent surface roughness and hardness specifications required for flow channels, functional surfaces, and sealing surfaces.

Following machining, stainless steel mirror polishing technology is utilized to improve wetted surface roughness, enabling high-quality, high-efficiency mirror polishing even on complex features.

The product's wetted surface roughness meets SEMI standards and surpasses the stringent requirements of leading international clients, enabling laminar gas flow with minimal turbulence to achieve rapid gas delivery response and corrosion resistance.

Learn more

Learn more

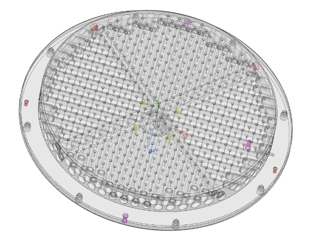

High Precision Micro-Hole Manufacturing Technology

Micro-hole fabrication is achieved through precise material control and processing. This technology also enables control over hole shape, size, and surface quality, thus meeting the requirements of diverse applications.

Professional high-speed drilling machines and AOI (Automated Optical Inspection) equipment for micro-hole processing and inspection.

Learn more

Learn more

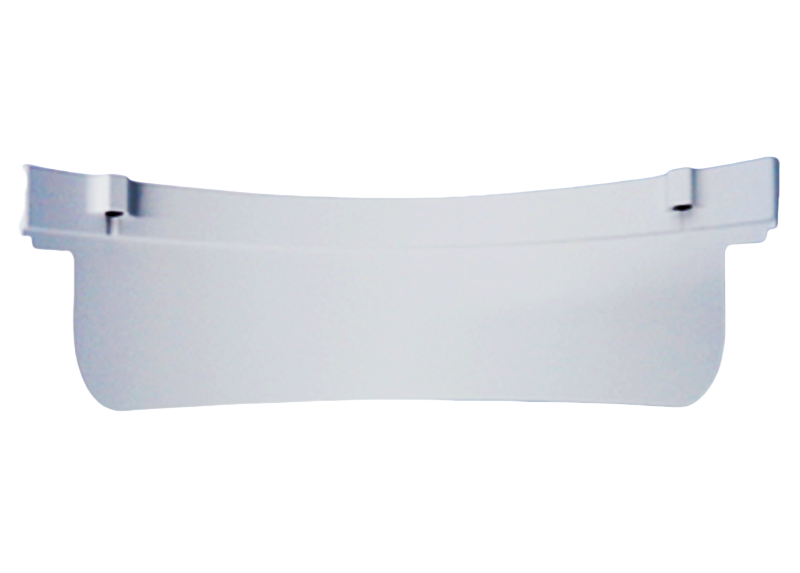

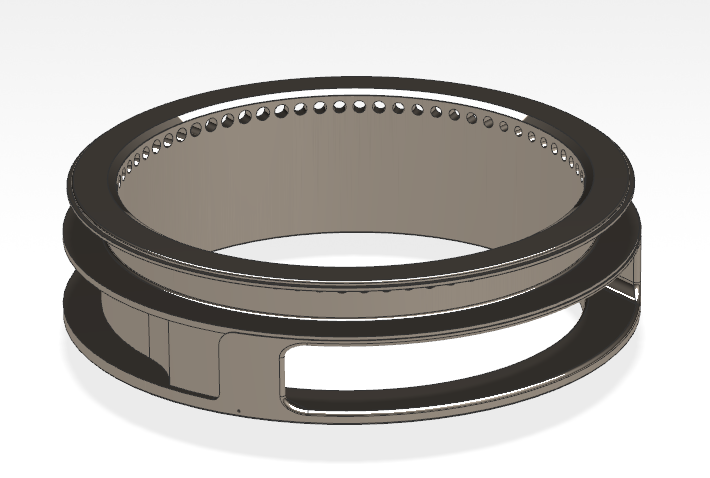

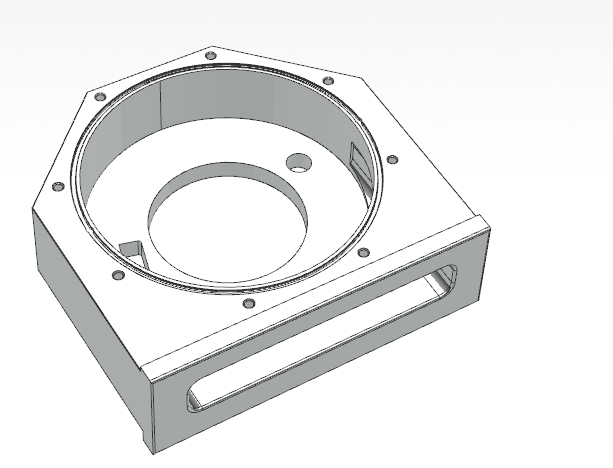

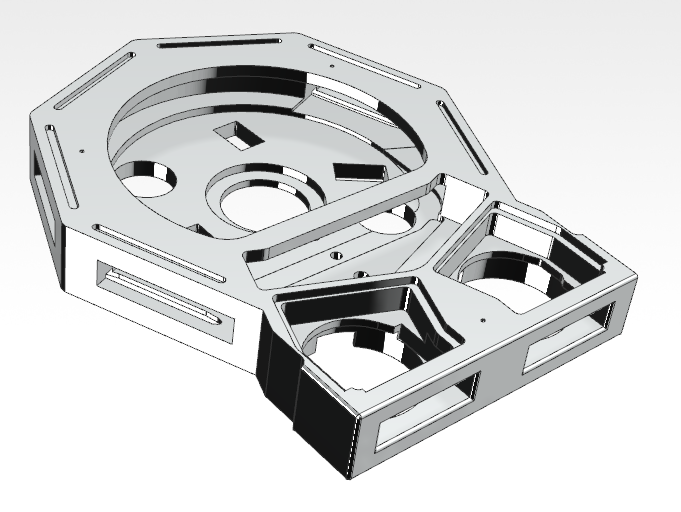

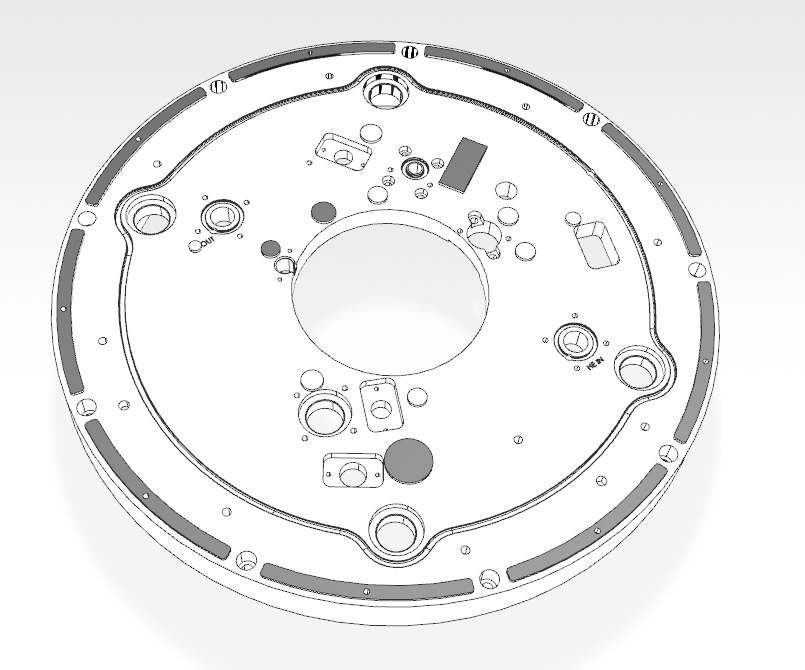

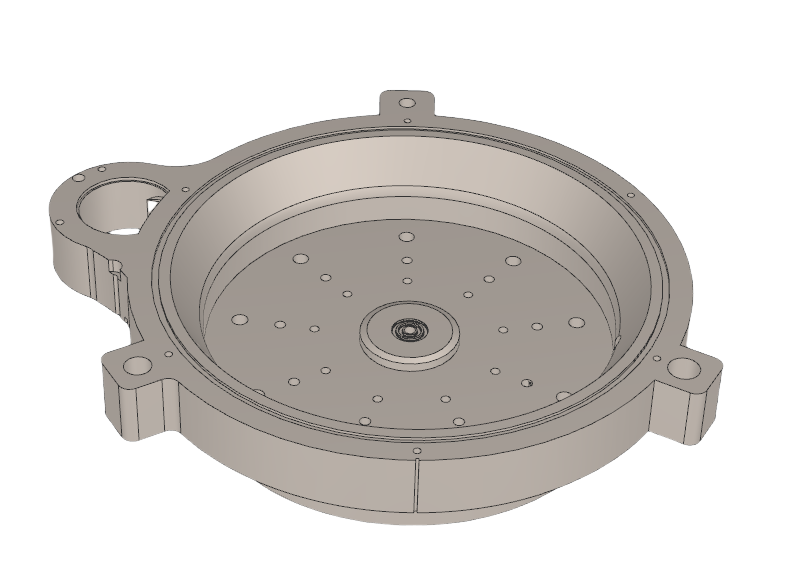

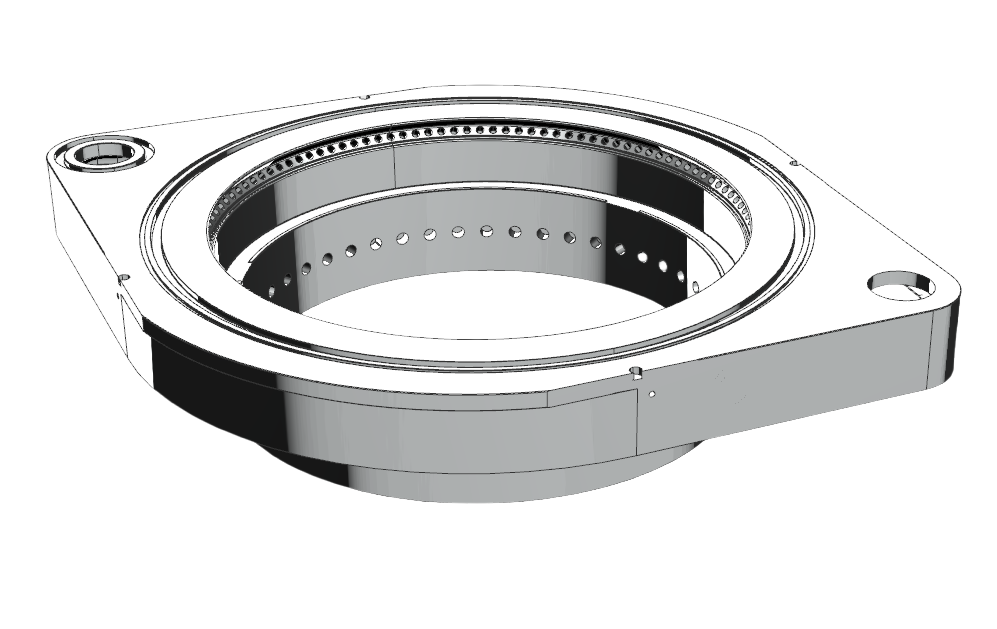

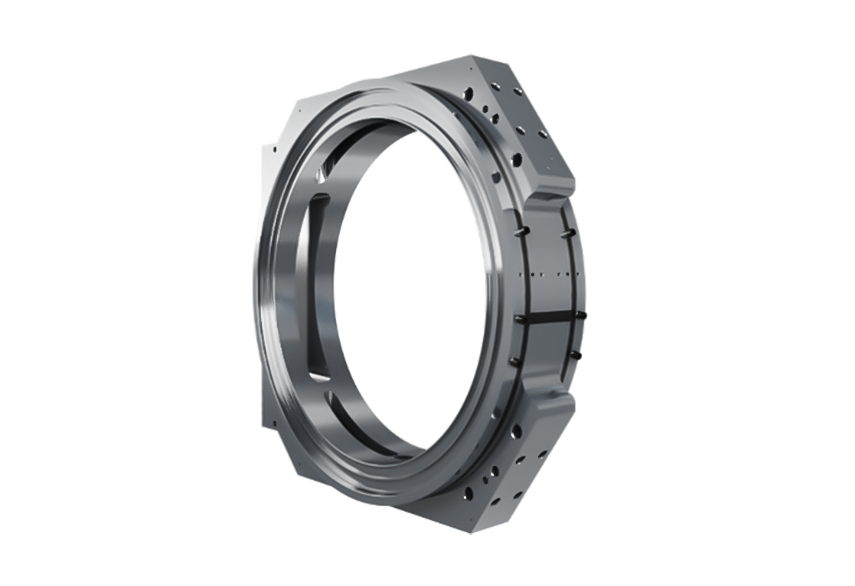

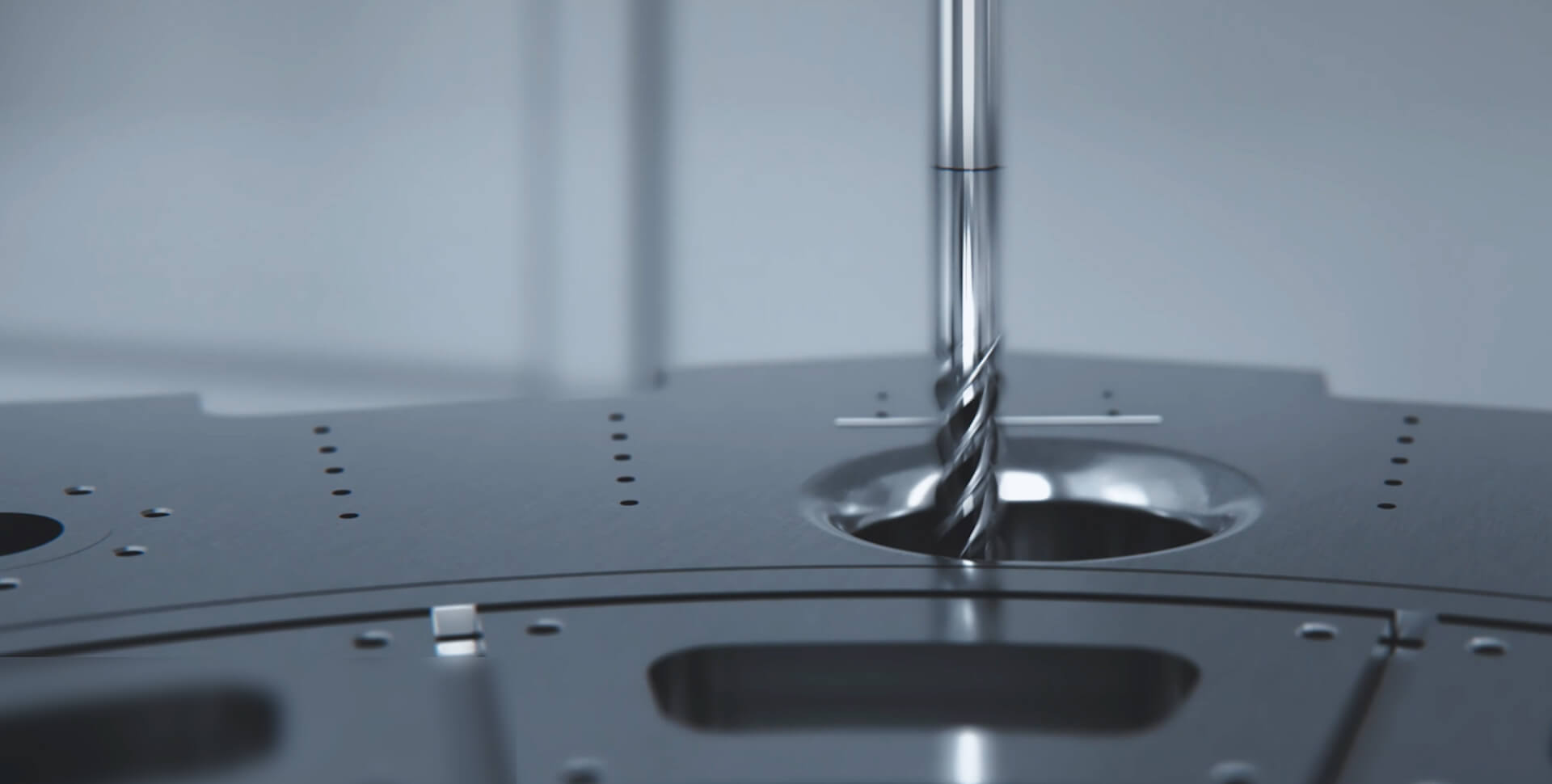

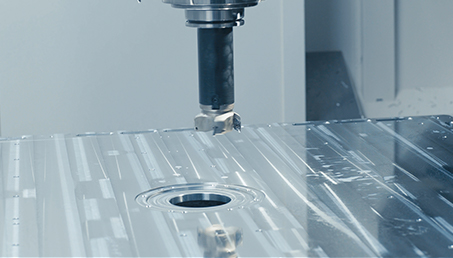

High Precision Multi-Station Complex Profile Manufacturing Technology

Complex surface multi-axis simultaneous machining enables one-stop fabrication of large-size chambers and multi-station features, while also providing integrated solutions such as chamber structure optimization and machining plan development.

Learn more

Learn more

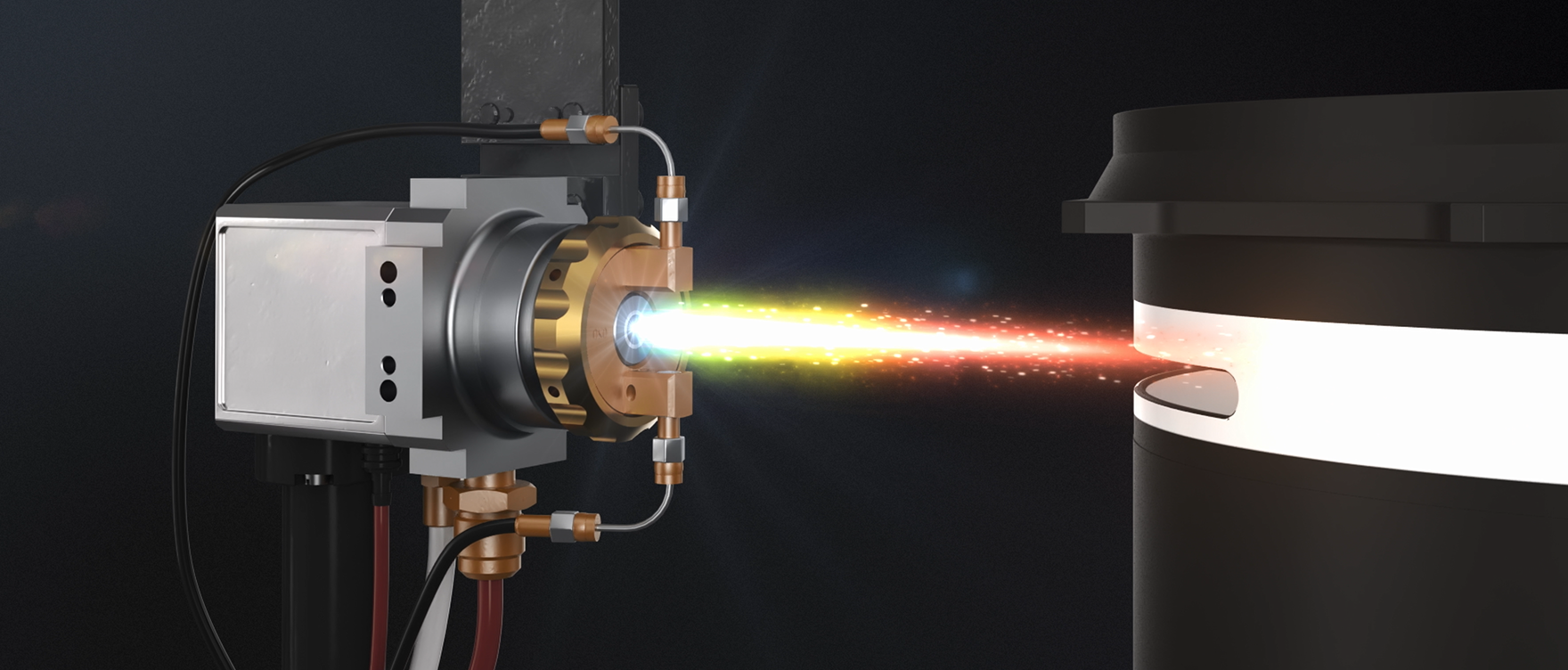

Plasma Spray Coating Technology

Plasma Spraying (PS) employs a DC power source to generate a high-temperature arc plasma between a cathode and an anode, facilitating the rapid thermal processing of materials, such as ceramics, to a semi-molten phase and subsequent deposition onto a substrate to create a coating layer.

Learn more

Learn more

Nanofilm Technology

Learn more

Learn more

Aluminum-Based Fluorination

This coating mitigates the reaction between ambient fluorine-containing plasma and the aluminum substrate, thereby ensuring uniform heater element temperature distribution and long-term thermal stability.

Learn more

Learn more

High-Performance Electroless Nickel Plating Technology

Certified by leading international clients, Electroless Nickel Plating technology offers a reliable coating solution that enhances component corrosion resistance, improves part performance, and ensures the stability of semiconductor equipment.

Learn more

Learn more

Corrosion-Resistant Anodizing Technology

Certified by leading international clients, a range of anodizing technologies (including Hard Anodizing, Sulfuric Anodizing, and Dyed Anodizing) provides reliable coating solutions that enhance component corrosion resistance, improve part performance, and ensure the stability of semiconductor equipment.

Learn more

Learn more

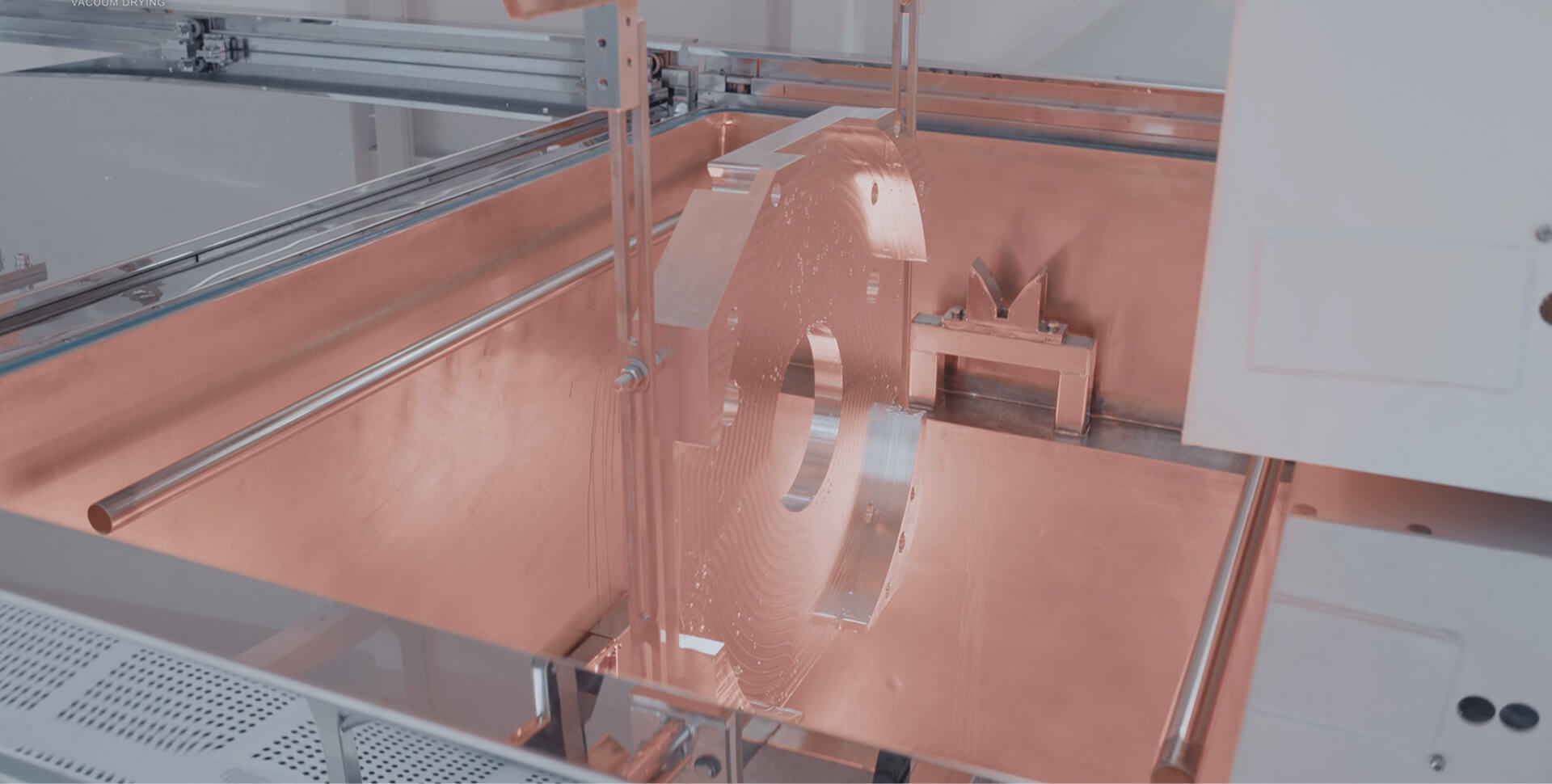

High-Cleanliness Precision Cleaning Technology

High-Cleanliness Precision Cleaning technology is certified by leading international clients, providing high-cleanliness cleaning solutions.

Learn more

Learn more

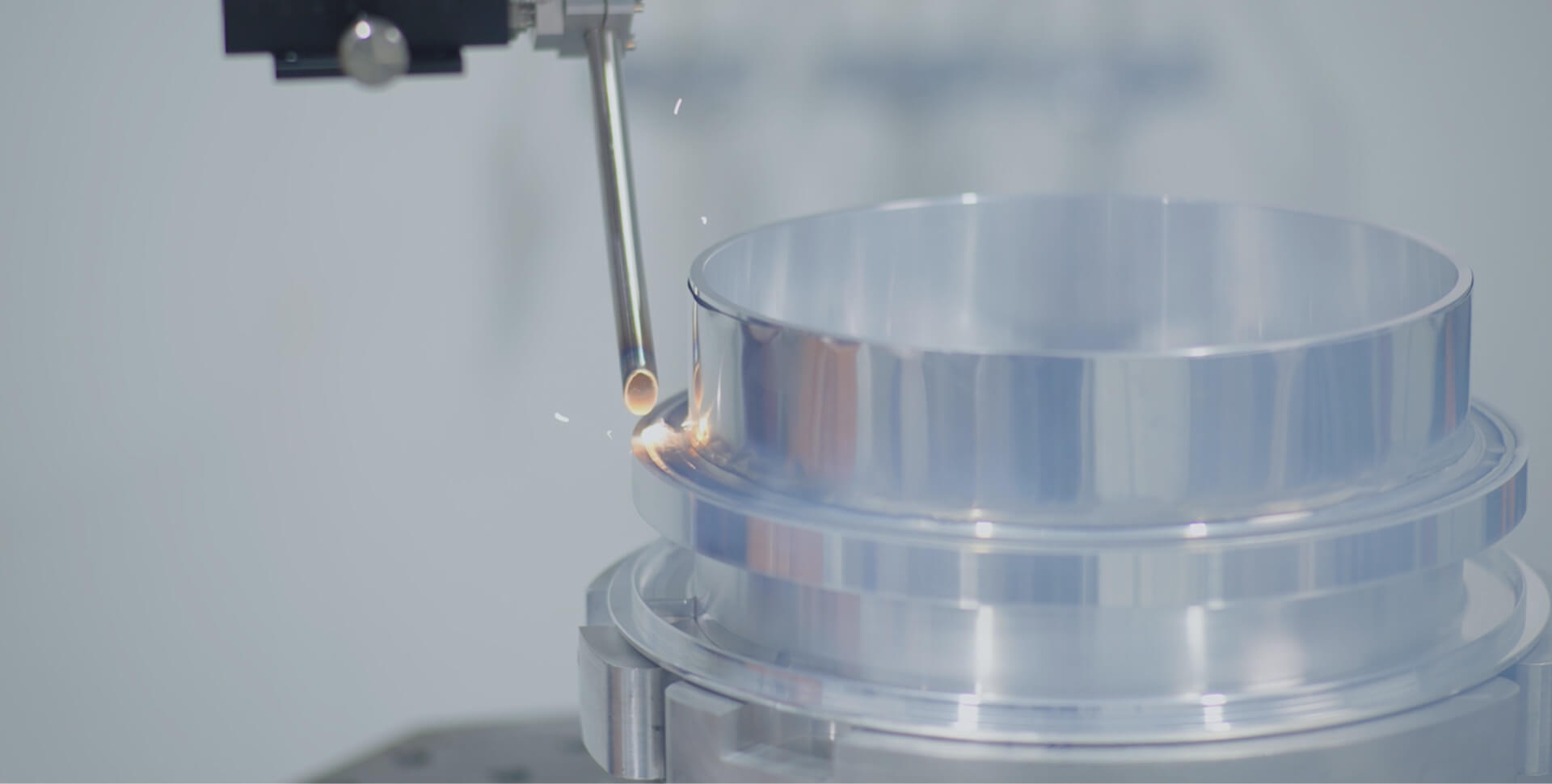

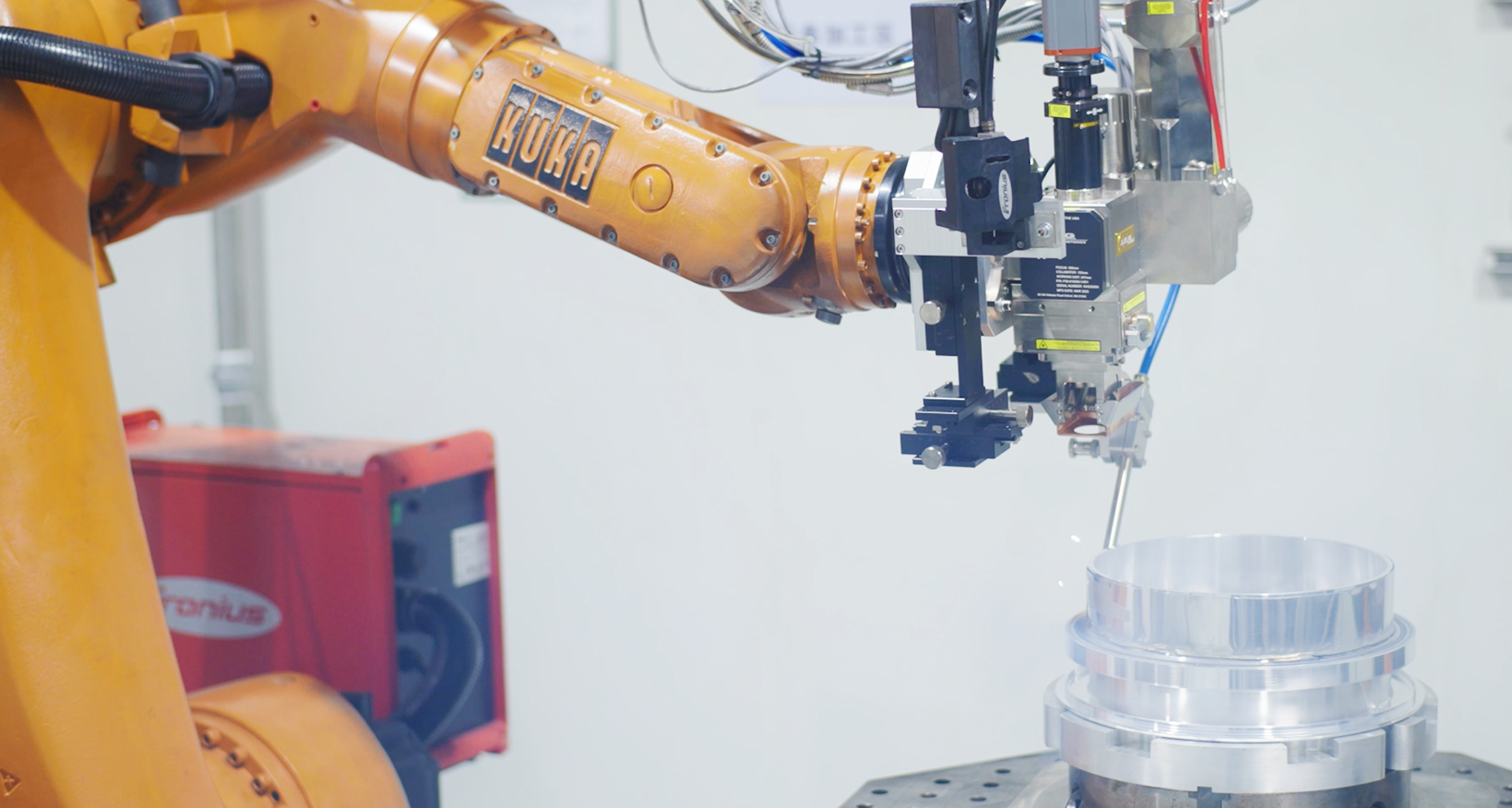

LBW Technology

Certified by leading clients and the AWS for laser welding, our processes ensure precise, complex, stable, repeatable, and high-quality welds. We also offer comprehensive welding design capabilities to provide effective solutions tailored to client needs.

Learn more

Learn more

EBW Technology

Utilizing imported German electron beam welding equipment, our processes are certified by leading clients and AWS. We deliver precise, complex, stable, repeatable, and high-quality welds, and offer comprehensive welding design capabilities to provide effective solutions tailored to client needs.

Learn more

Learn more

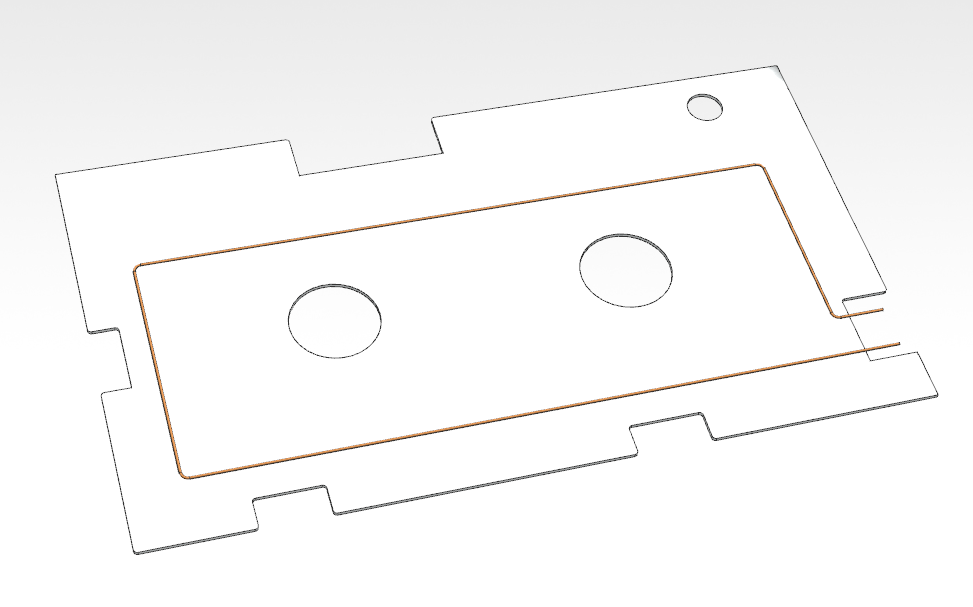

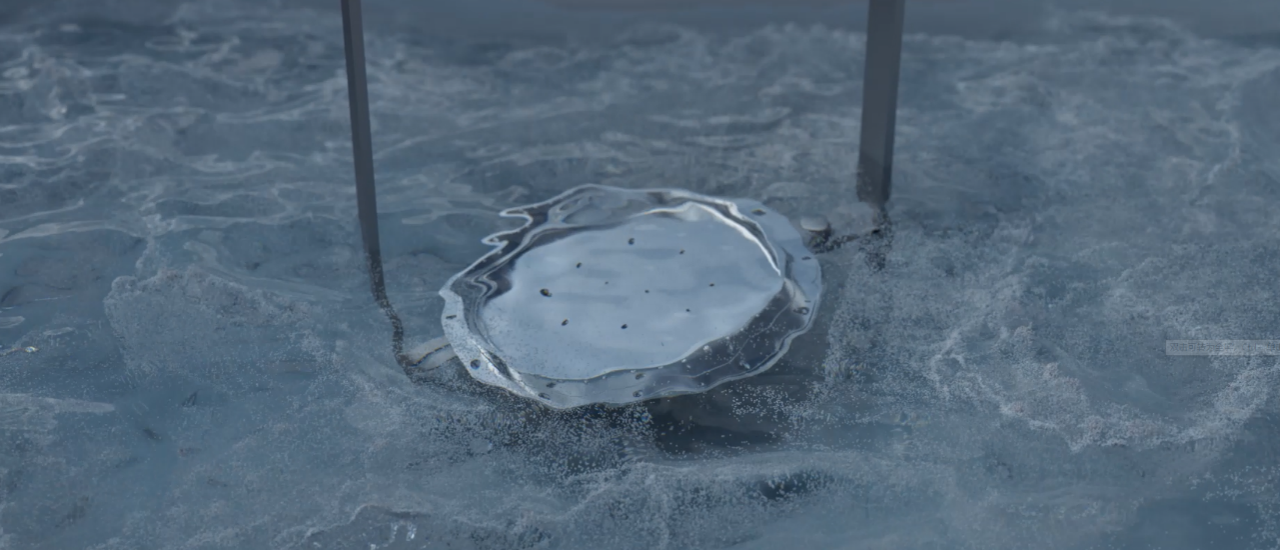

Brazing Technology

In the vacuum brazing process, two or more materials are joined by an intermediate layer of one or more filler materials (usually braze alloy). This process is executed within a vacuum or reduced-pressure atmosphere to minimize the partial pressure of oxygen and other reactive species, thereby inhibiting oxidation and other deleterious reactions. The brazing alloy melts at a lower temperature and creates a strong bond between the materials.

Learn more

Learn more

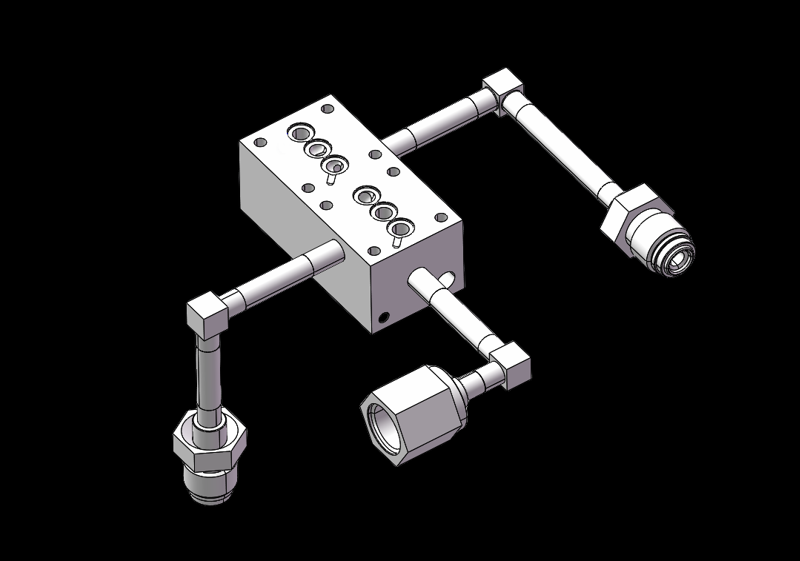

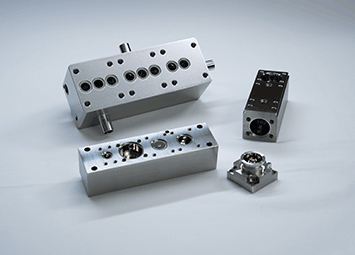

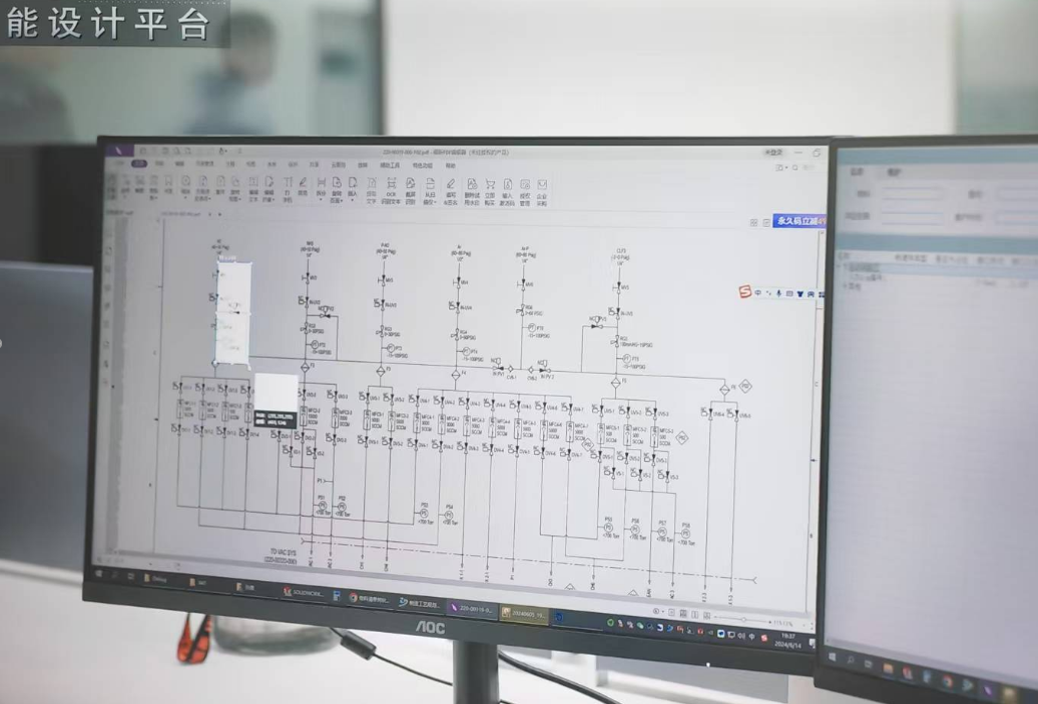

Ultra-Clean Gas Cabinet Design Technology

Our company has extensive experience in the design of ultra-clean gas transmission Gas cabinets, covering over 80% of dry-process gas transmission Gas cabinets used in front-end semiconductor manufacturing processes. We have independently developed an intelligent design platform that revolutionizes traditional design methodologies, enabling standardization and modularization of Gas Cabinet designs. Through the implementation of a standardized database system, we achieve both high-quality and high-efficiency design outputs.

Learn more

Learn more

Ultra-Clean Gas Line Welding Technology

Leveraging advanced welding equipment and unique welding processes, our company is committed to producing gas line welding products that meet and exceed semiconductor industry standards.

Learn more

Learn more

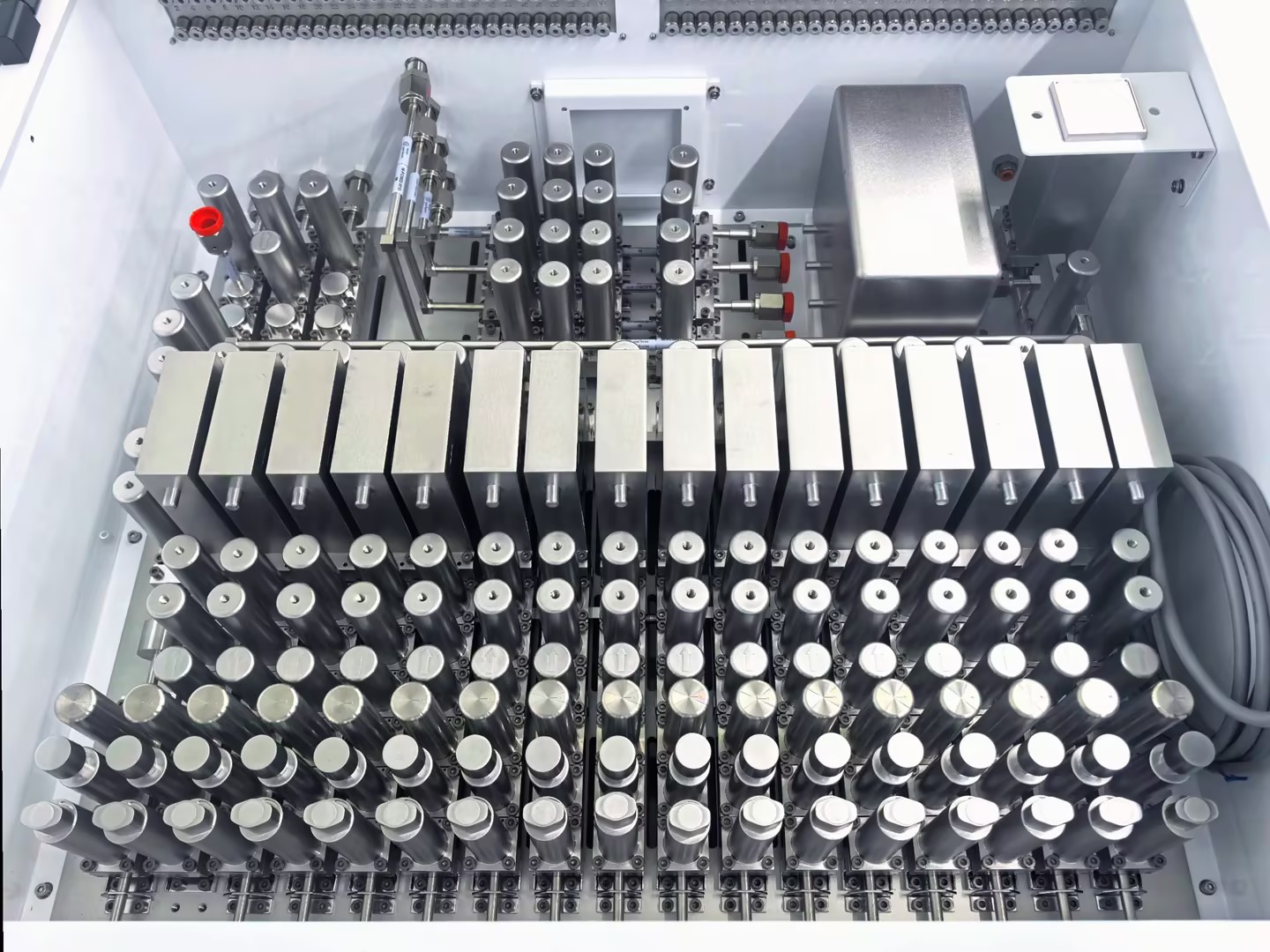

Ultra-Clean Gas Cabinet Manufacturing Technology

Our company is committed to establishing a globally leading gas cabinet assembly and production line, pioneering a superior semiconductor gas cabinet manufacturing model, and enhancing overall efficiency and quality. Driven by these objectives and adhering to stringent gas cabinet production process standards, we have independently developed an automated production line that surpasses traditional manufacturing methods, providing enhanced process quality control.

Learn more

Learn more

Ultra-Clean Gas Cabinet Testing Technology

This project delivers a comprehensive, automated, and data-driven platform that significantly enhances testing efficiency and quality, improves detection capabilities, and domestically leading gas delivery system functional testing device.

Learn more

Learn more