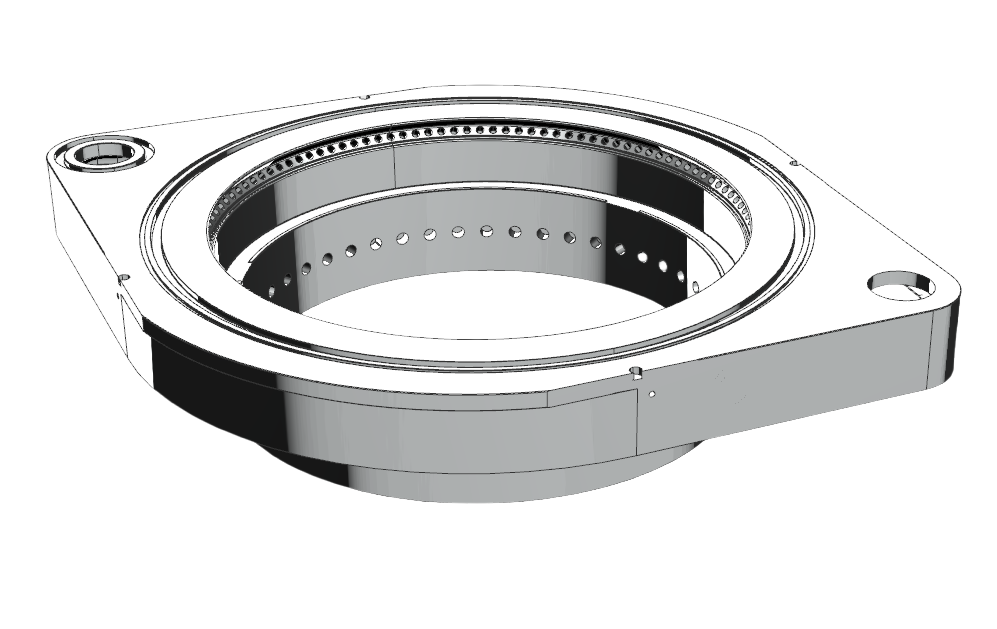

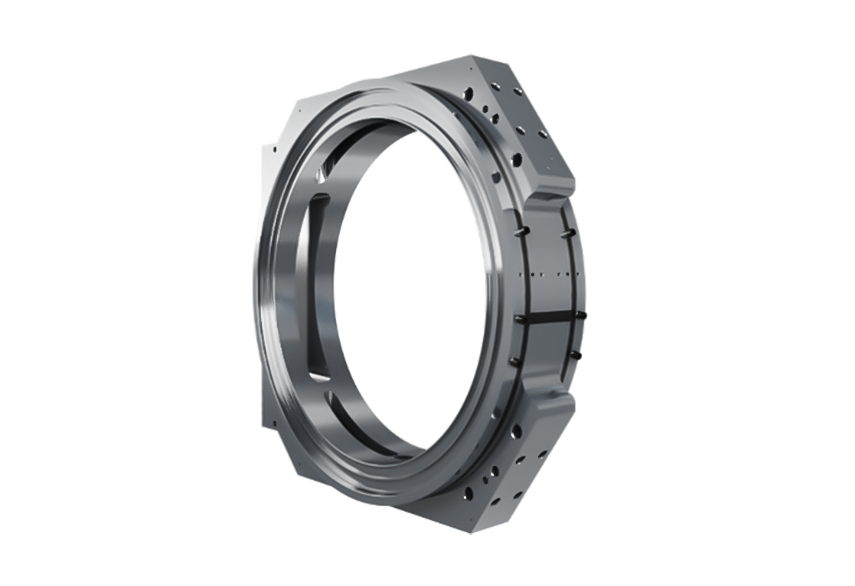

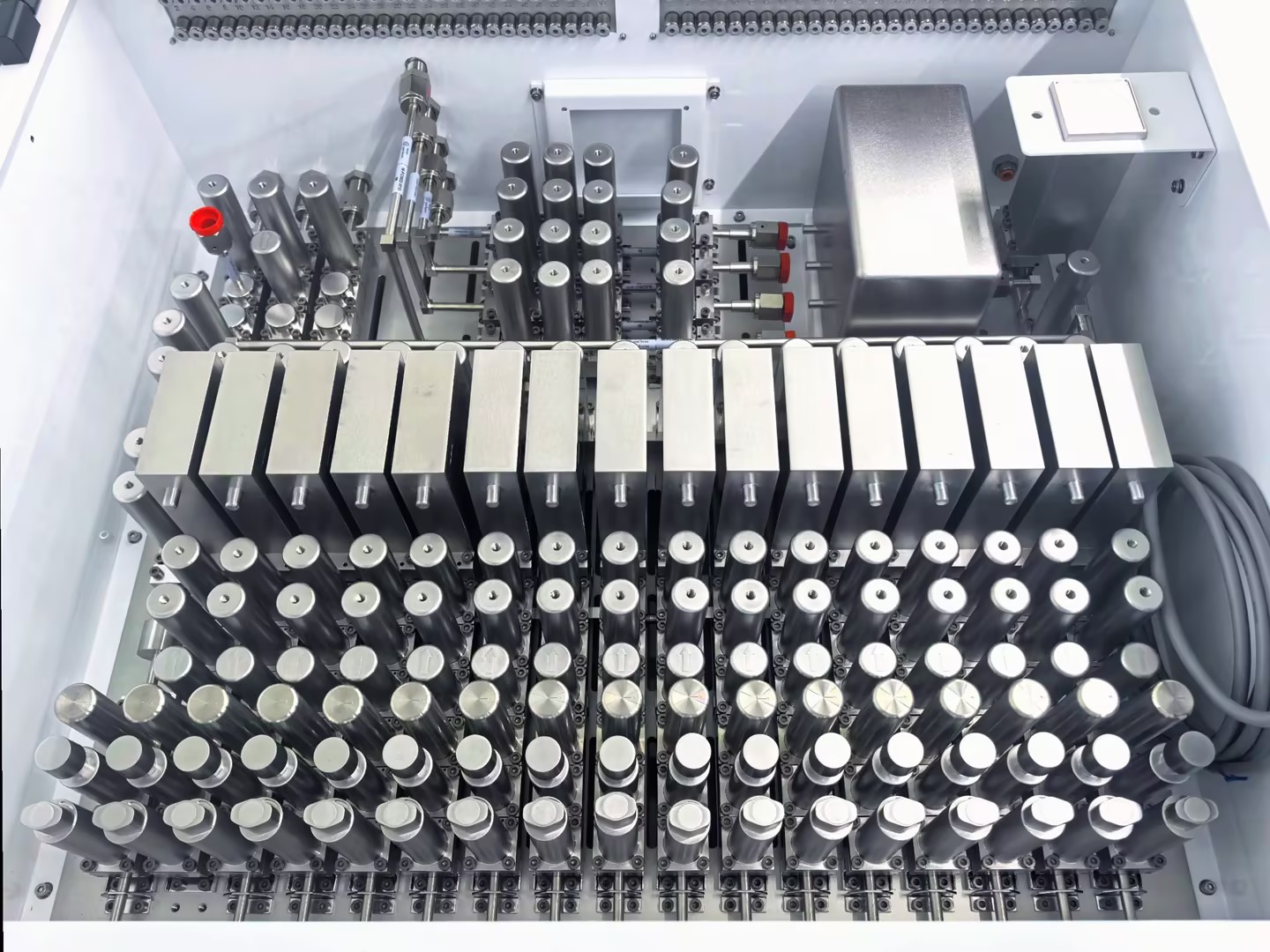

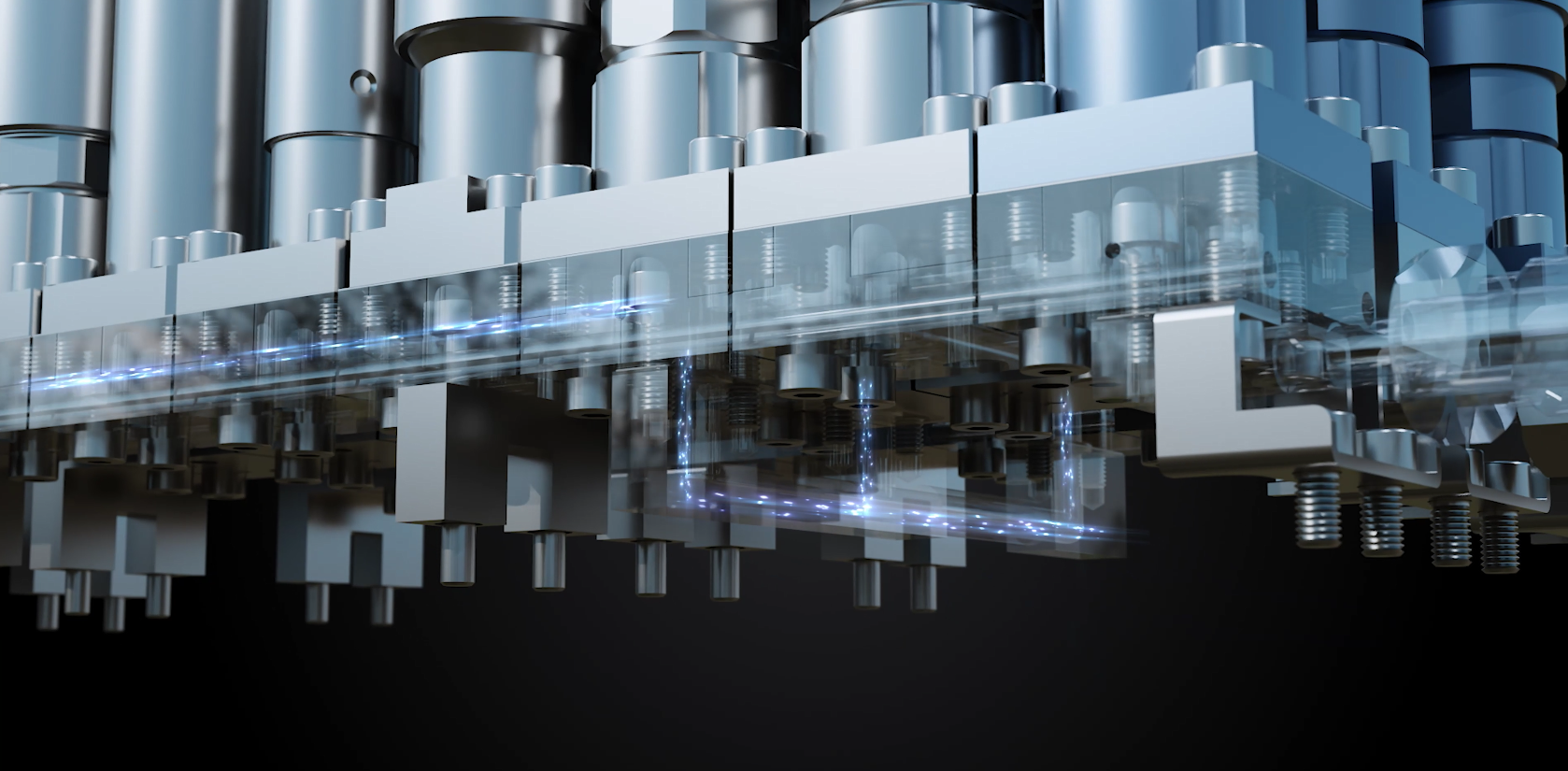

CVD Process GasCabinet

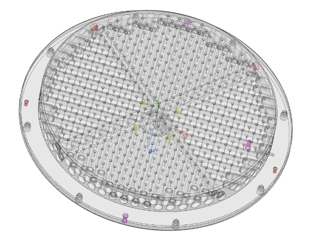

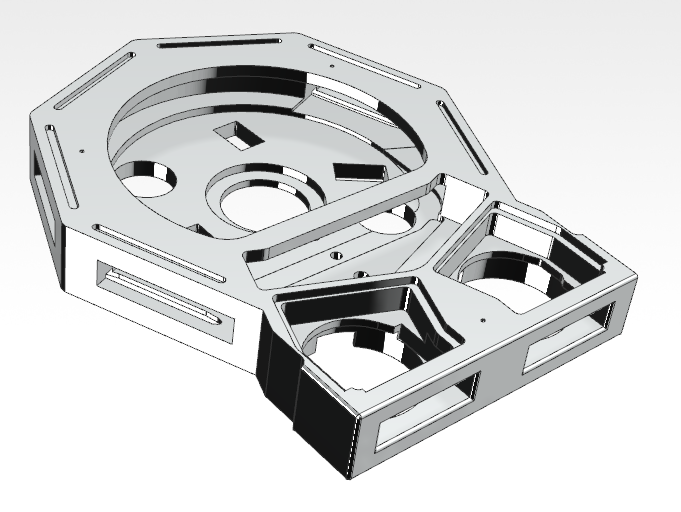

The three major processes - thin film deposition, photolithography, and etching - are the most critical steps. The CVD Process Gas Delivery Control Cabinet is an indispensable part of the Chemical Vapor Deposition (CVD) process, primarily used for precise control of the transmission and supply of special gases, ensuring gas purity, stability, and safety during the CVD process.

Consult an Expert

Consult an Expert

-

Product Features

-

Product Parameters

Product Features

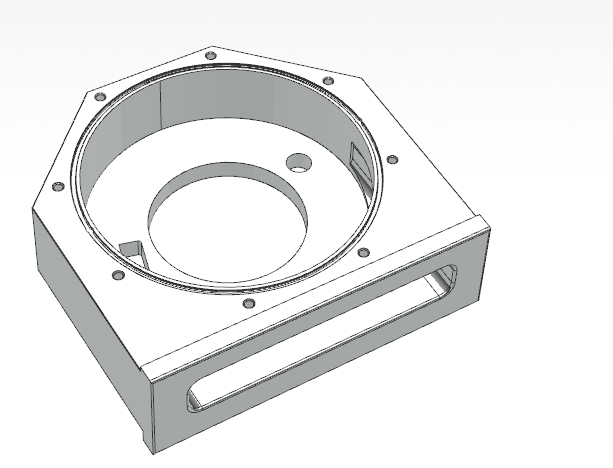

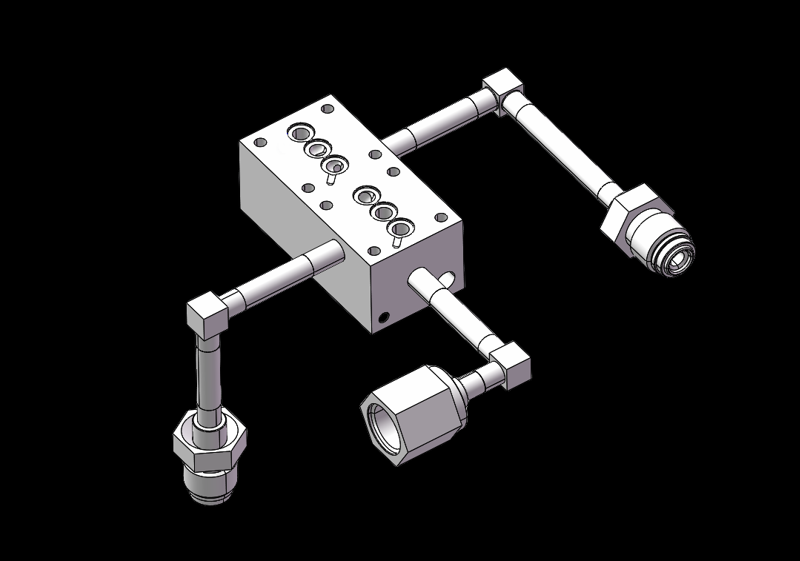

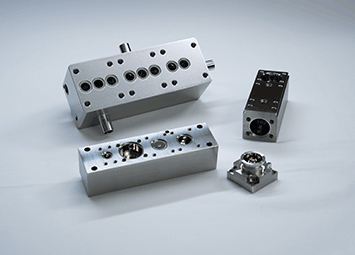

High precision flow control:

High-precision valve systems and flow controllers implement accurate delivery and management of specialty gases, ensuring the stability of critical parameters such as gas flow rate and pressure.

Safety and Stability:

The gas box is equipped with safety components such as door interlock switches, pressure safety switches, check valves, and flame detectors to ensure safety. Simultaneously, the equipment incorporates explosion-proof, corrosion-resistant designs, enhancing safety performance.

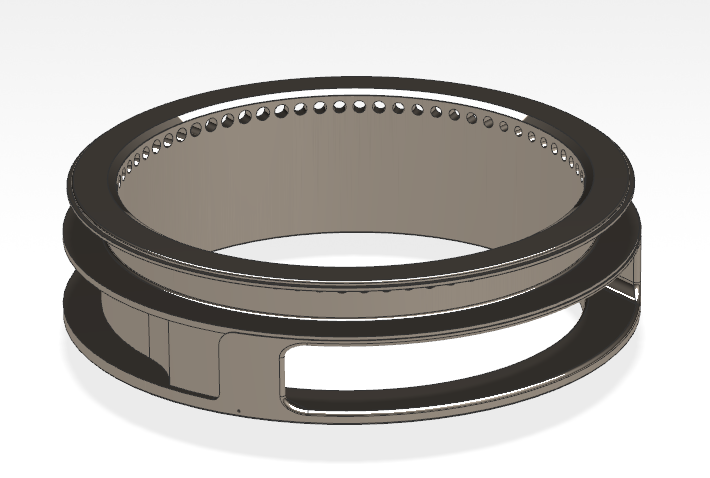

High Airtightness:

The product utilizes IGS and VCR interface types to achieve high airtightness for semiconductor equipment.

High Cleanliness:

Designed for the removal of particle impurities, this system utilizes high precision filters with a retention rating of 3 nm.

Safety Certification:

Passed SEMI S6 safety certification testing.

Product Parameters

| Outboard leakage rate test: | ≤1.0X10-11/mbar·L/s |

| Inboard leakage rate at seat: | ≤1.0X10-9/mbar·L/s |

| Pressure hold test 50psi: | Nitrogen pressure hold test, hold for 12h, pressure drop ≤1% |

| Helium into a bag leakage rate: | ≤1.0X10-9/mbar·L/s; (Optional) |

| Particle test: | (5 particle @ >0.1um) |

| Moisture and oxygen test: | Moisture content ≤10 PPB, Oxygen content ≤10 PPB; (Optional) |