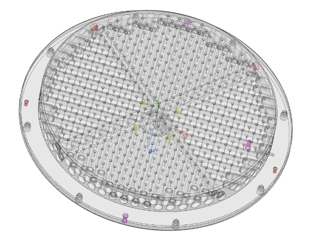

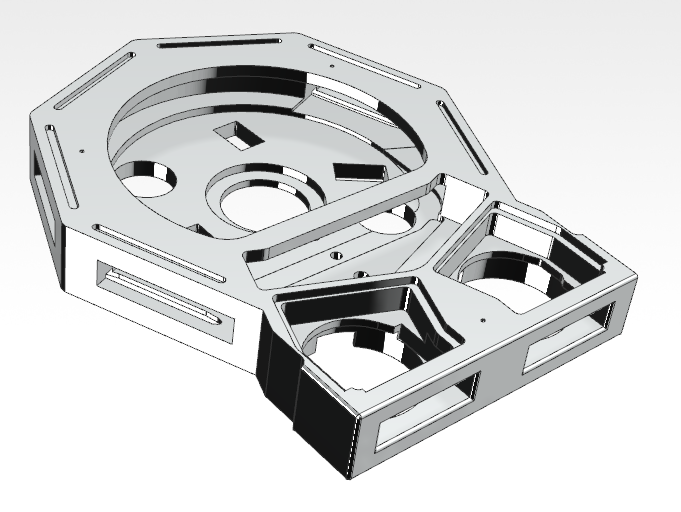

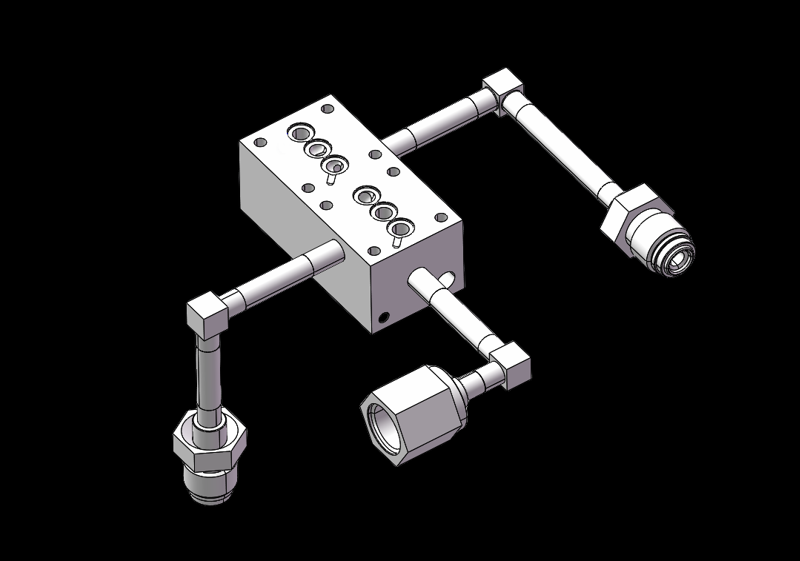

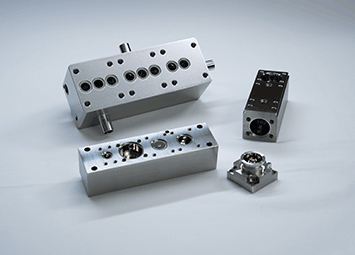

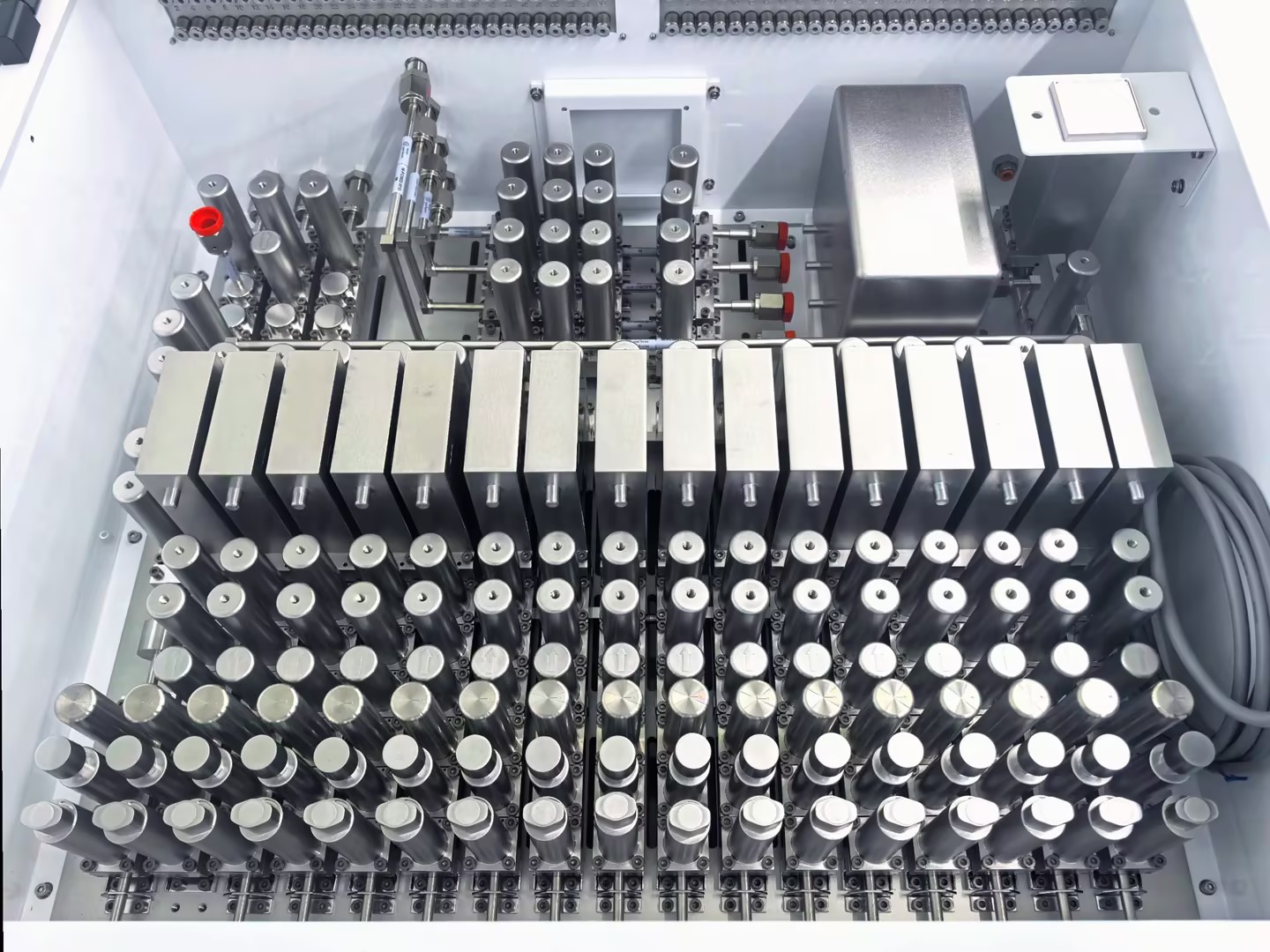

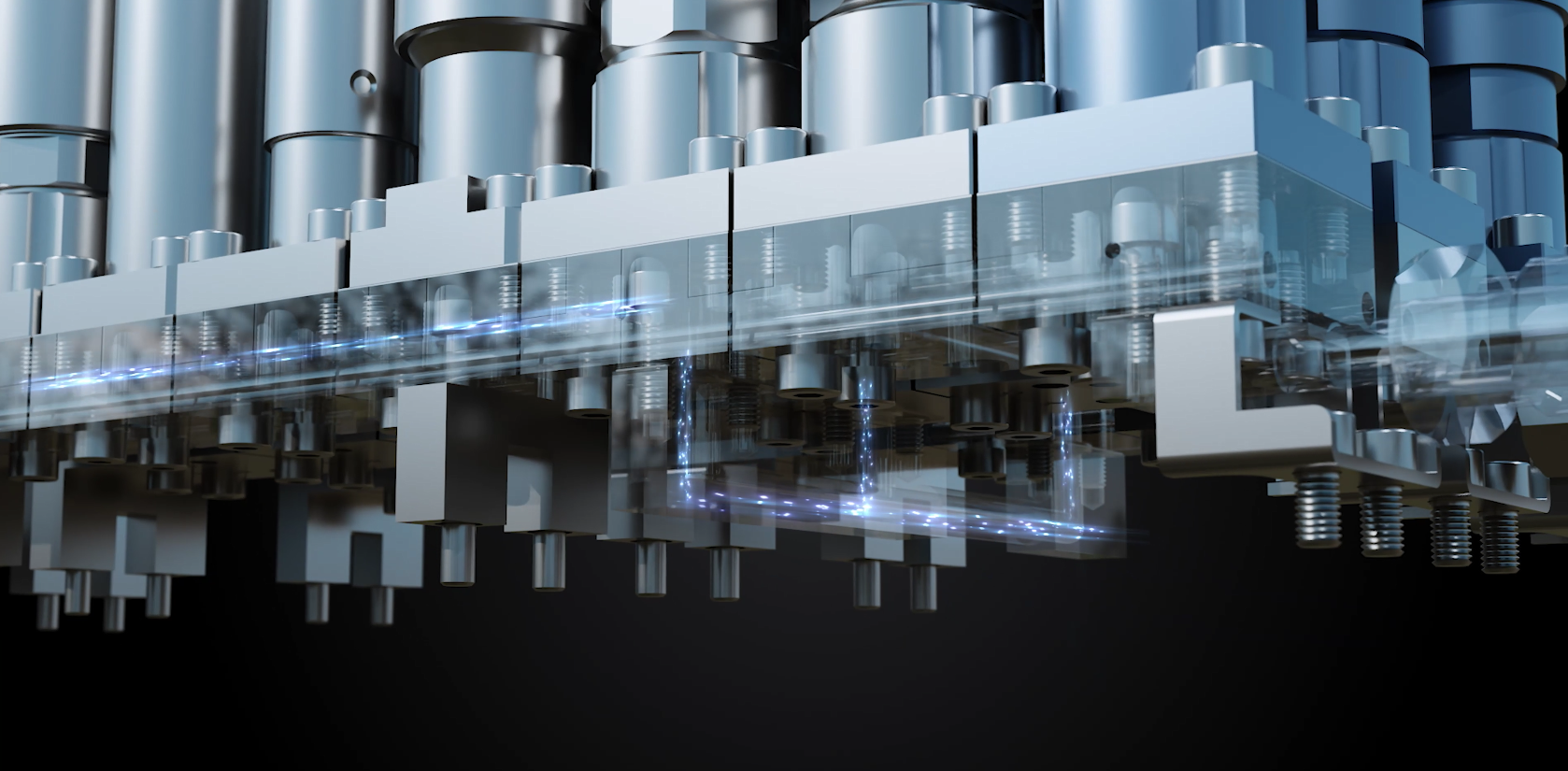

Maniflod block&Gas Lines

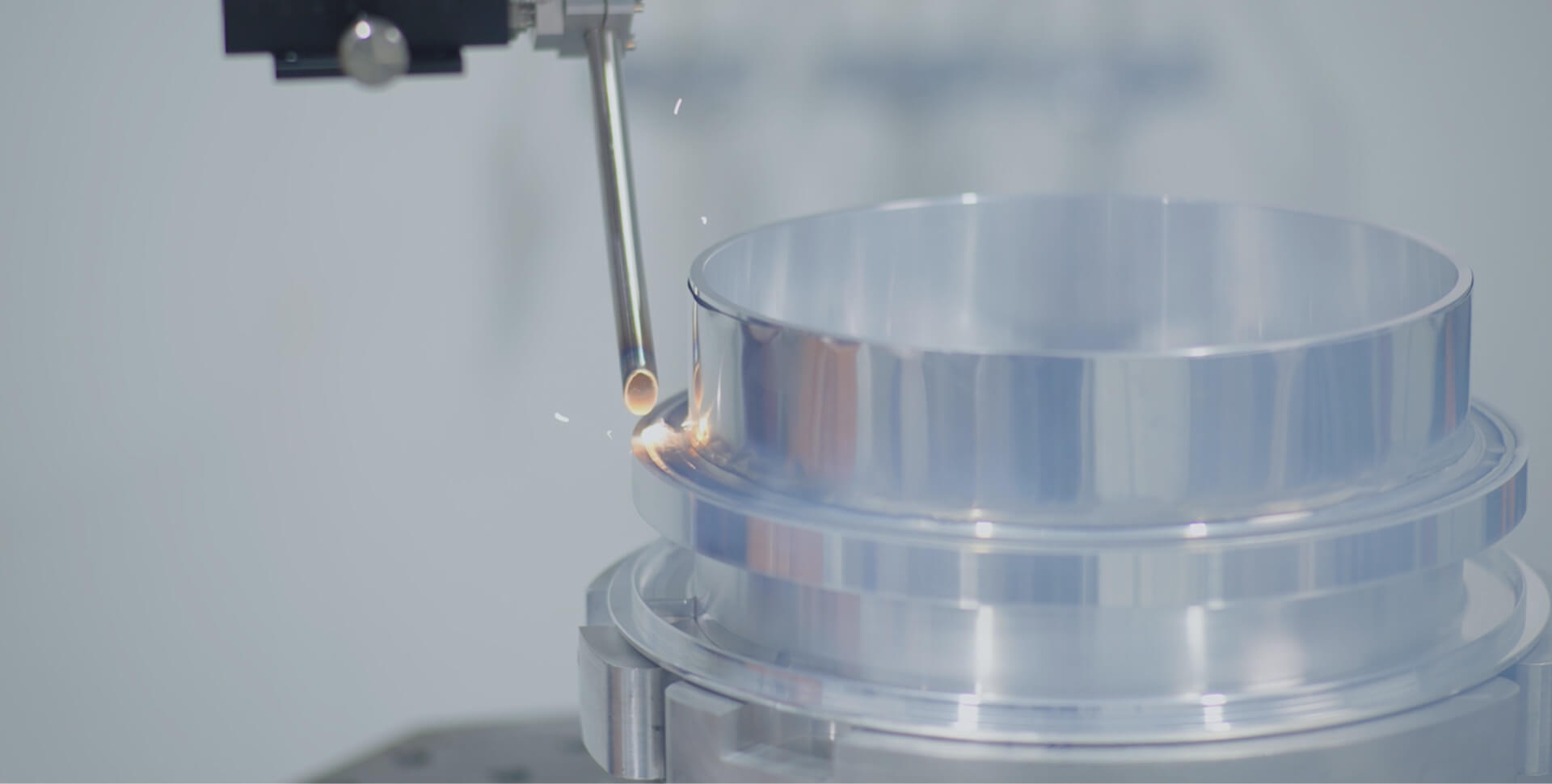

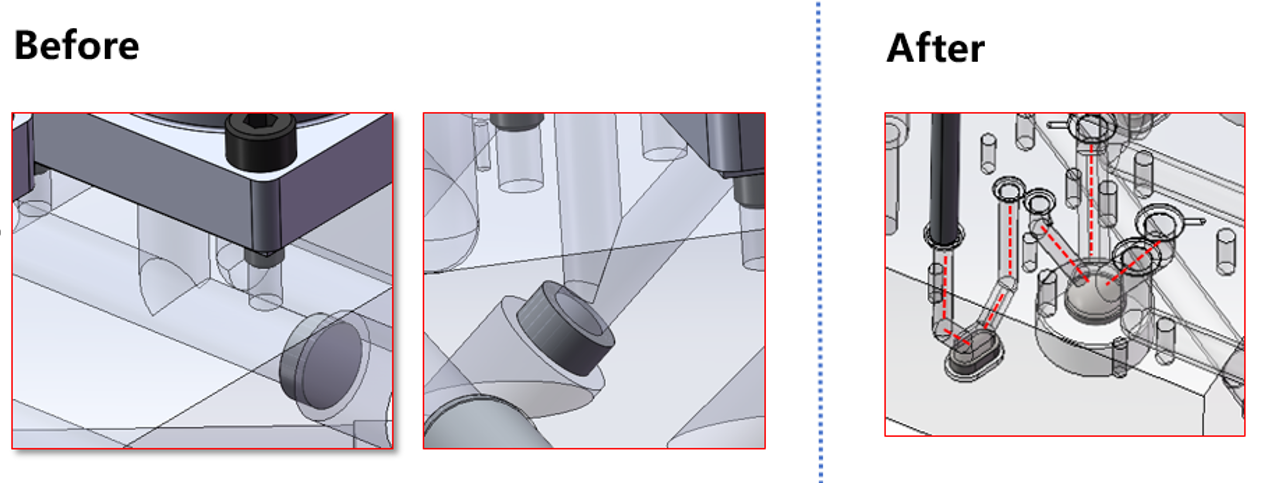

The assembly structure of UHP Gas Lines and IGS block is realized through the welding of custom-designed block and VCR fitting to enable individual gas line to have the same function. Compared with the traditional assembly design structure, it reduces the leakage risk caused by assembly and the overall space size can be reduced by about 20%.

Consult an Expert

Consult an Expert

-

Product Features

-

Related Solutions

Product Features

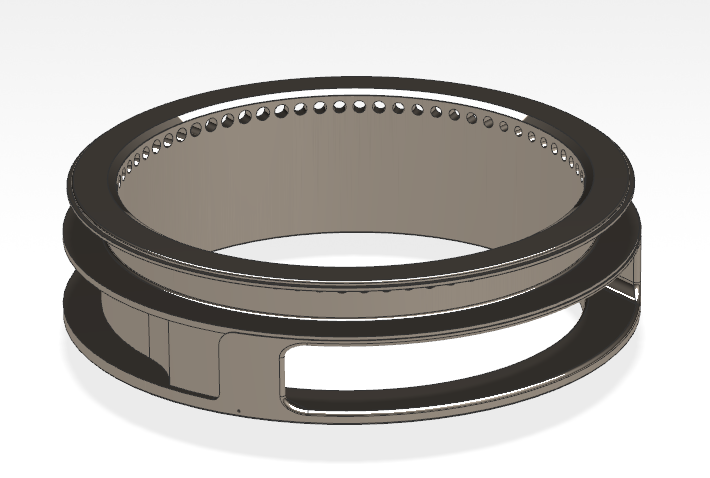

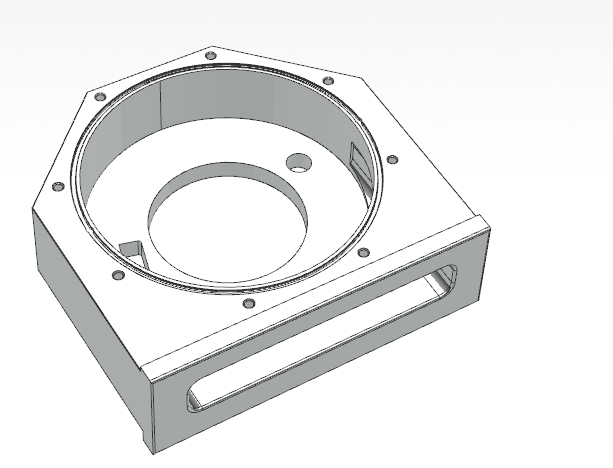

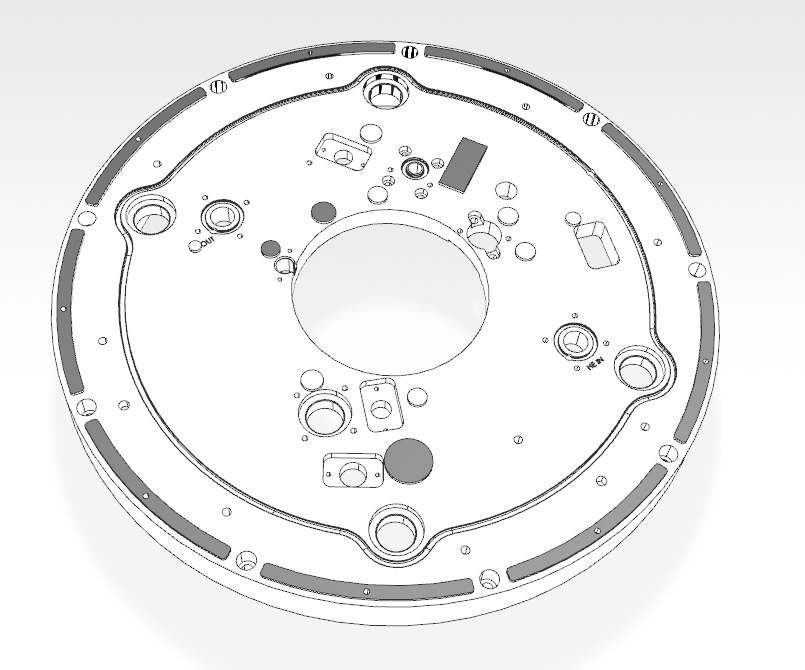

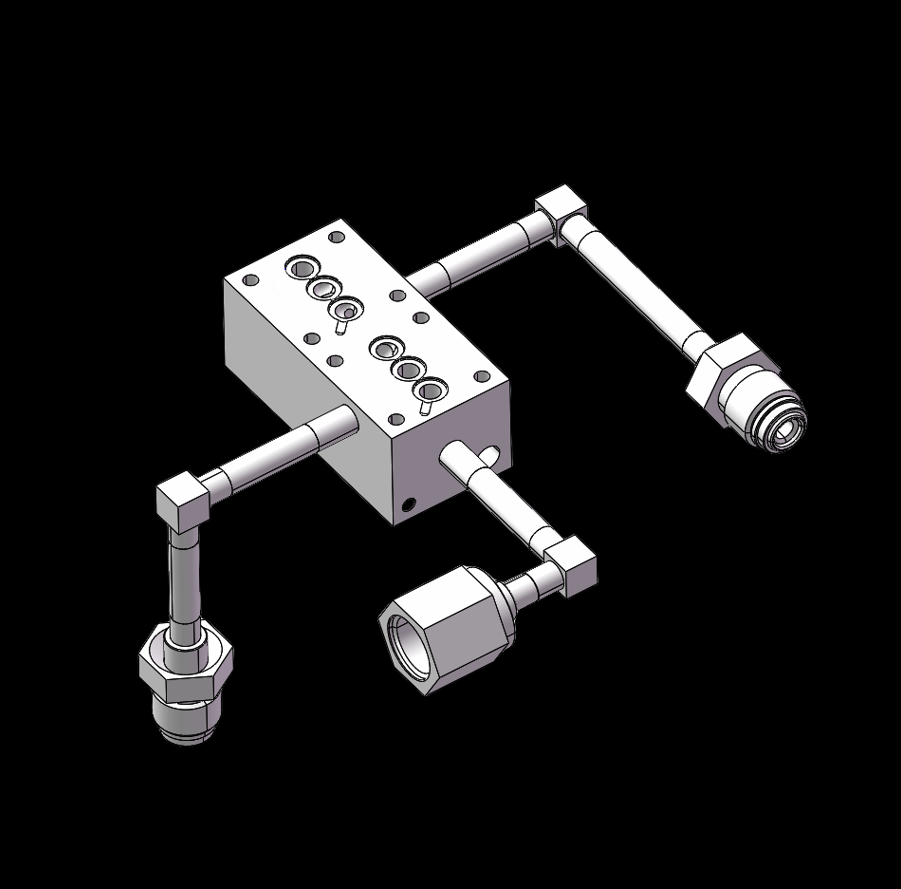

High Integration:

In accordance with process design requirements, gas delivery line are integrated within one BLOCK, thereby minimizing gas delivery distances and reducing overall space size.

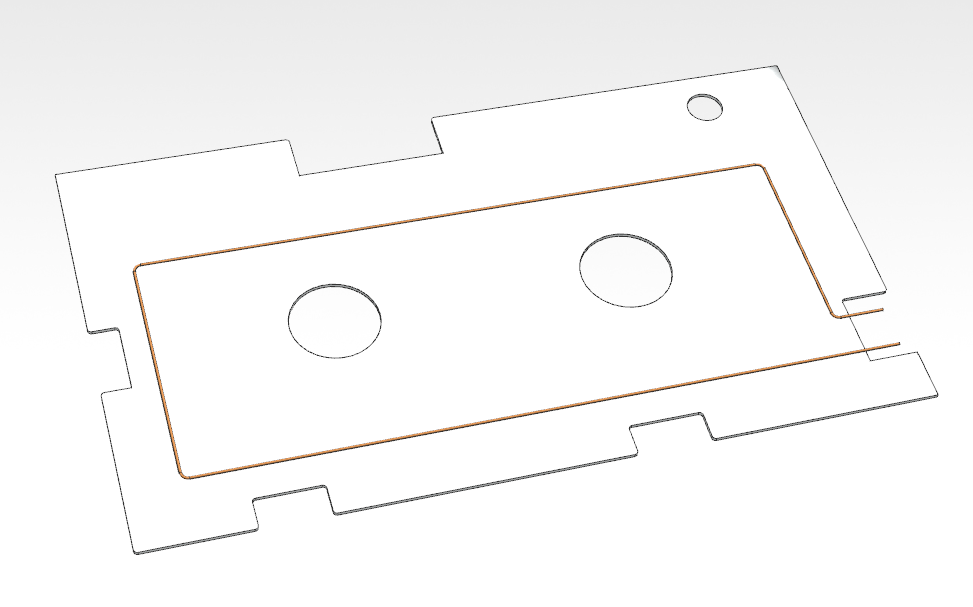

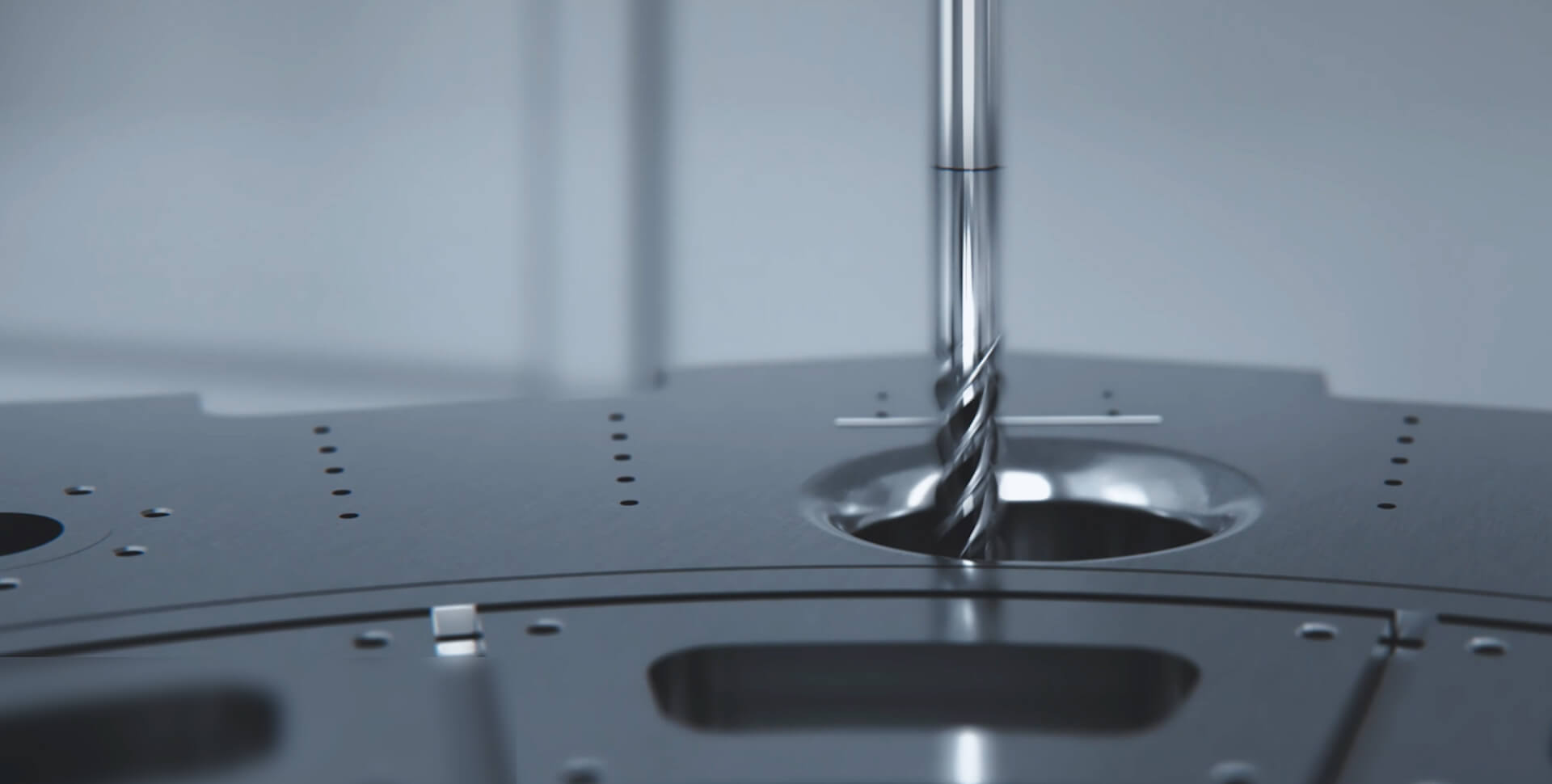

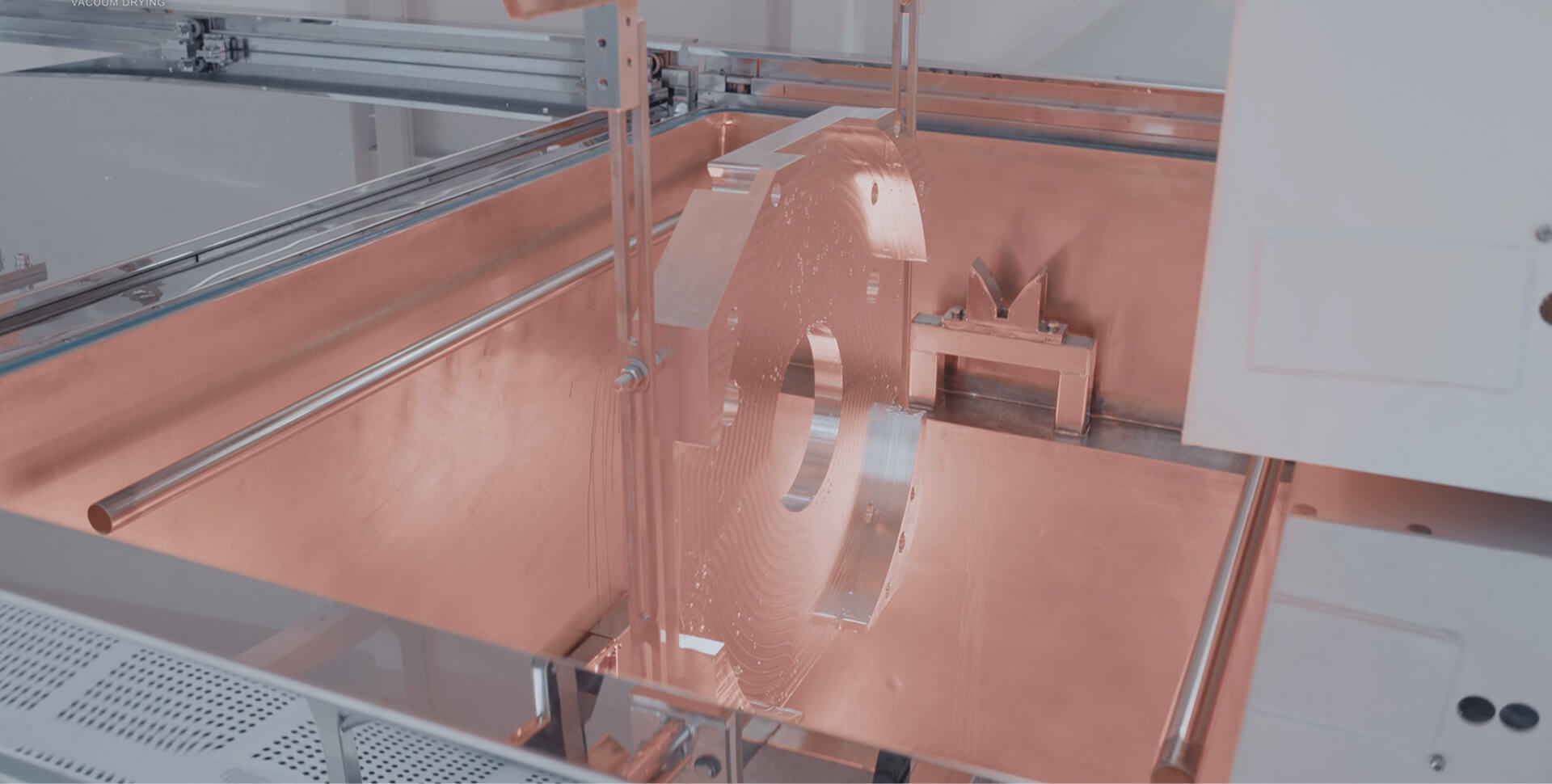

High Cleanliness:

Raw material inner surfaces are electropolished (EP) ensure that the roughness below Ra 0.25 μm. UPW cleaning, welding, testing, and packaging are performed within a Class 5 cleanroom environment. UPW with a resistivity of ≥18 MΩ·cm is used for cleaning.

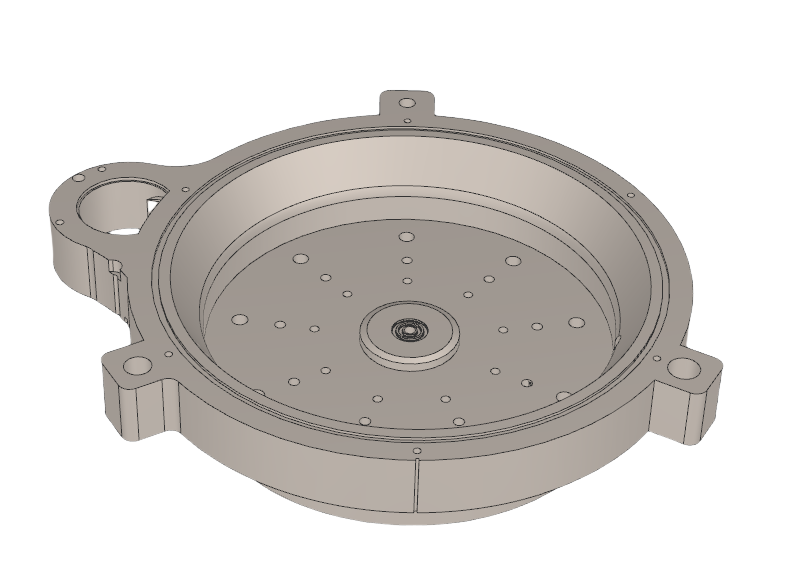

High Corrosion Resistance:

All raw materials are HP & UHP grade 316L stainless steel, inner surfaces electropolished (EP) . By reducing the roughness value of the inner surface of the material, the residual particles and moisture inside the pipe can be decreased, thereby enhancing the corrosion resistance of the parts.