EPI Process GasCabinet

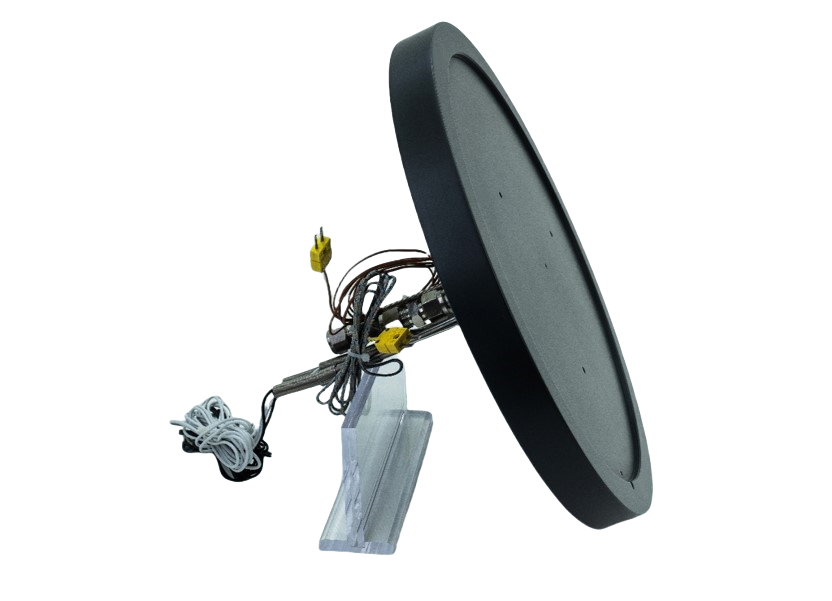

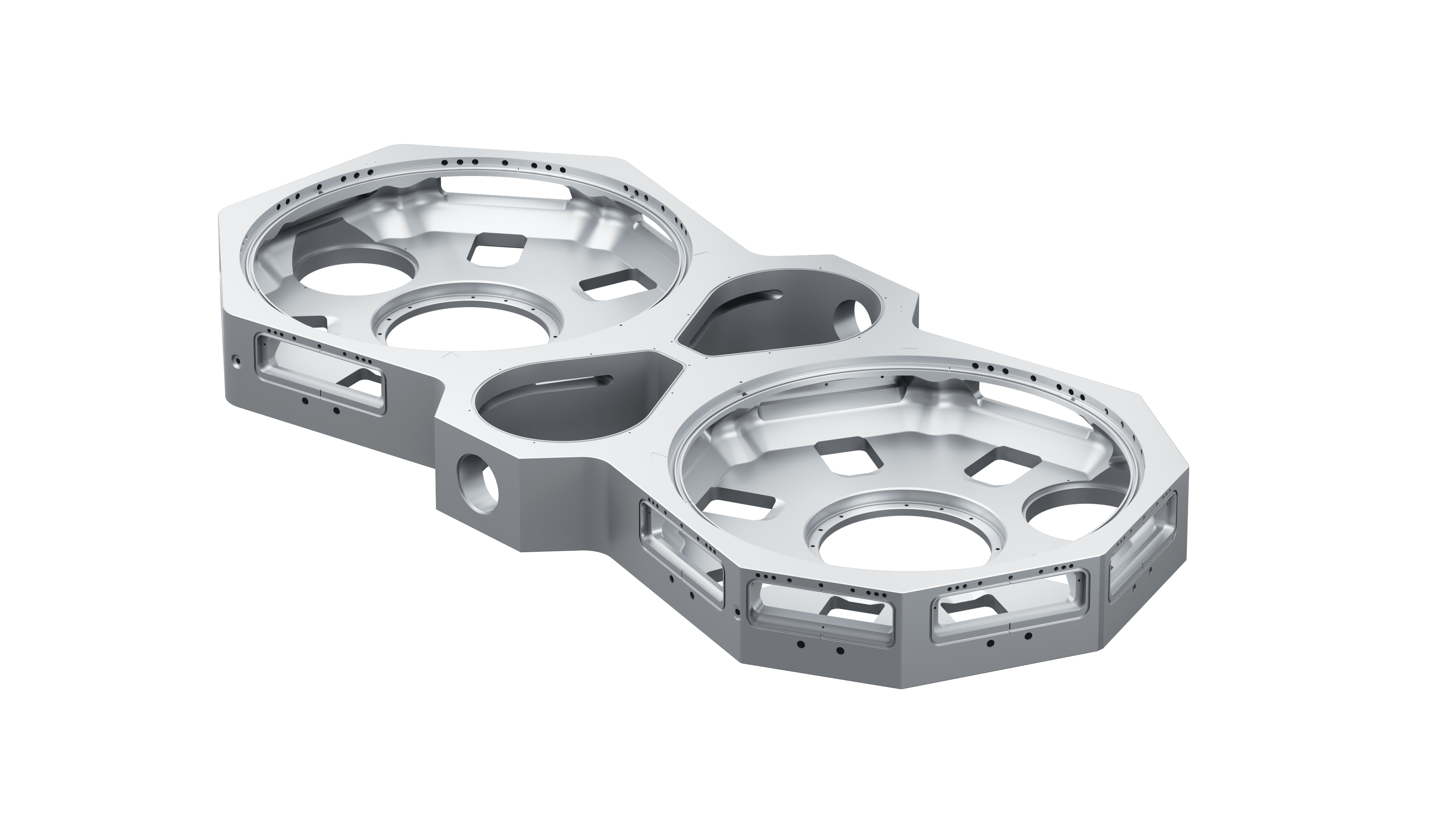

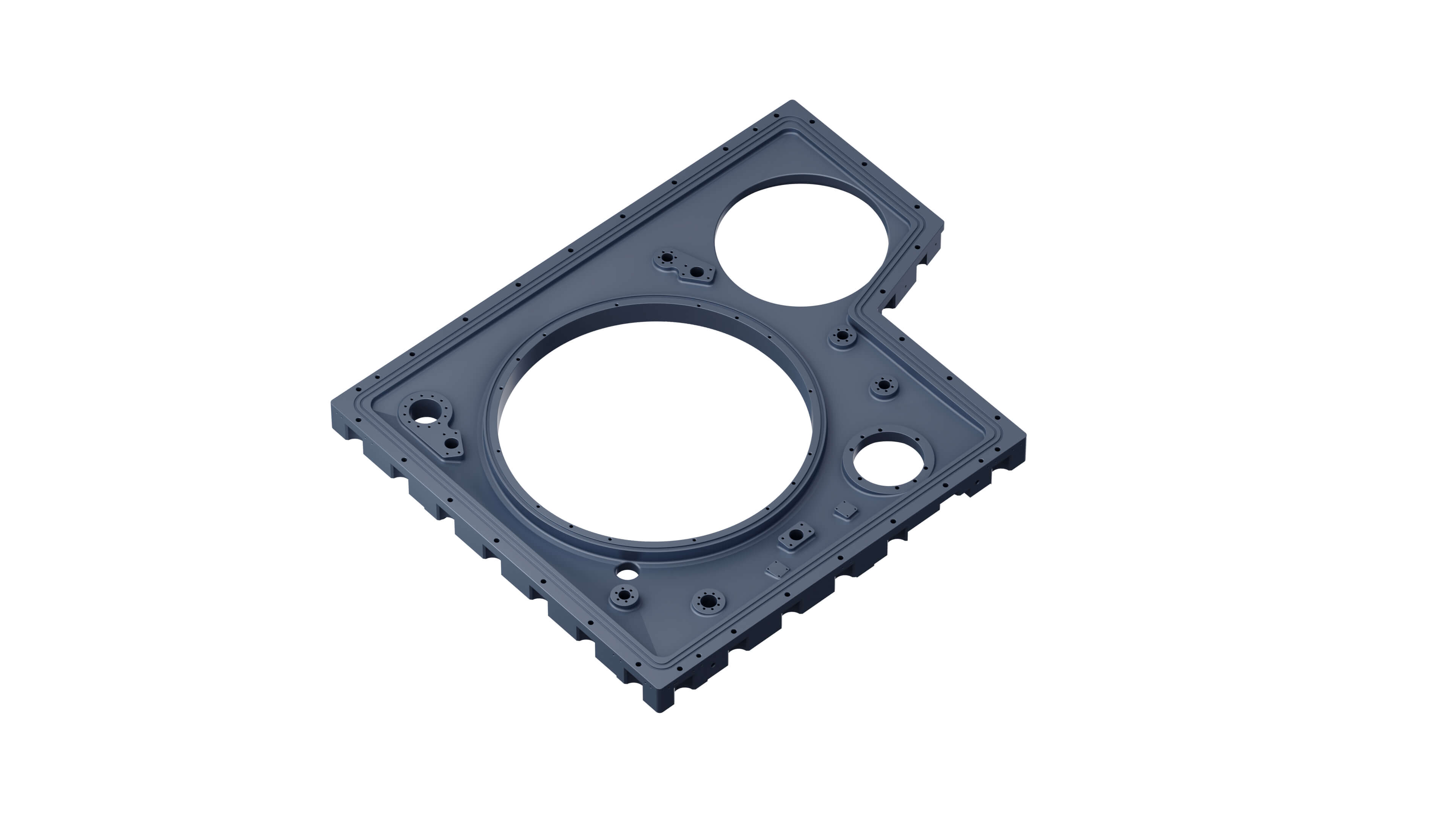

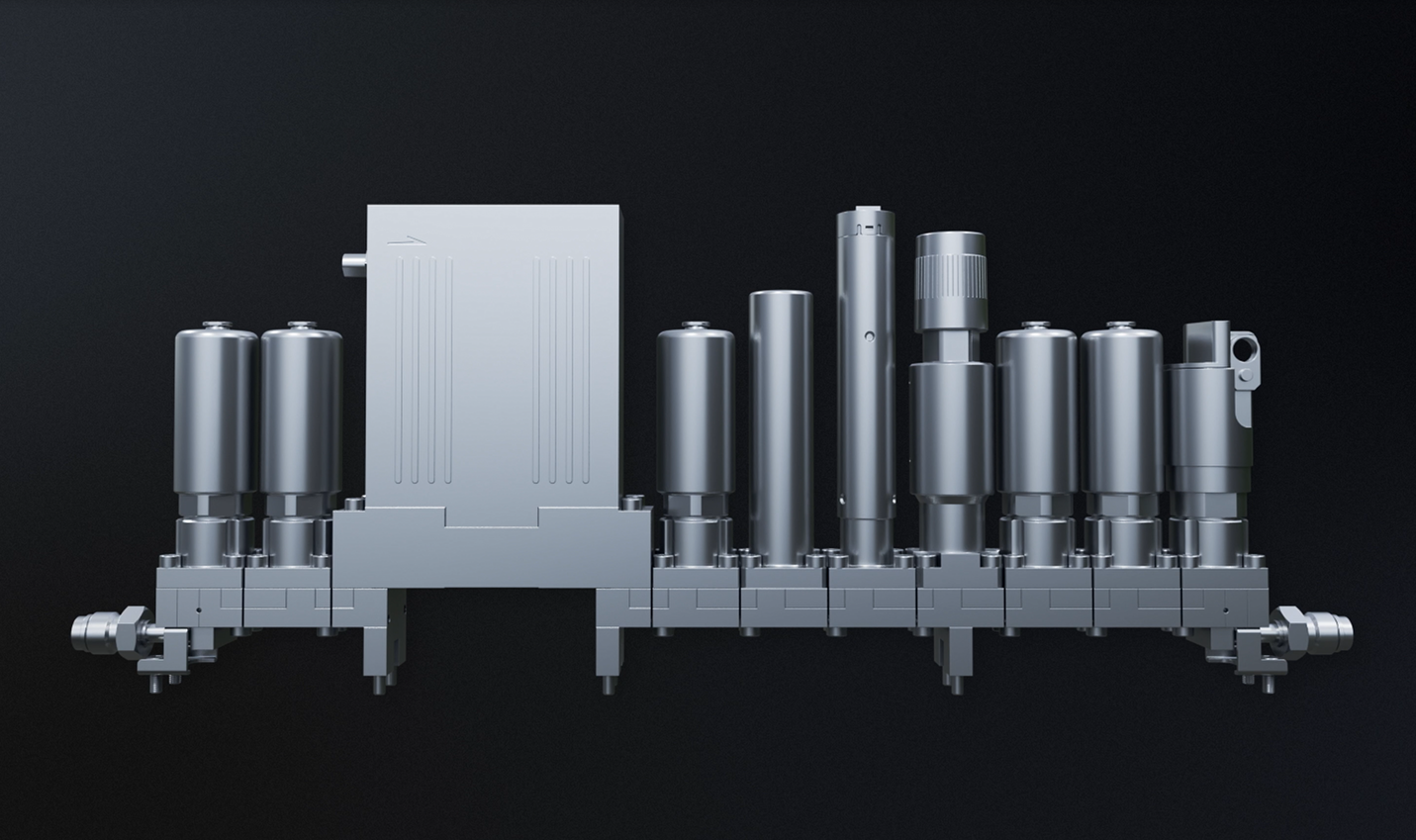

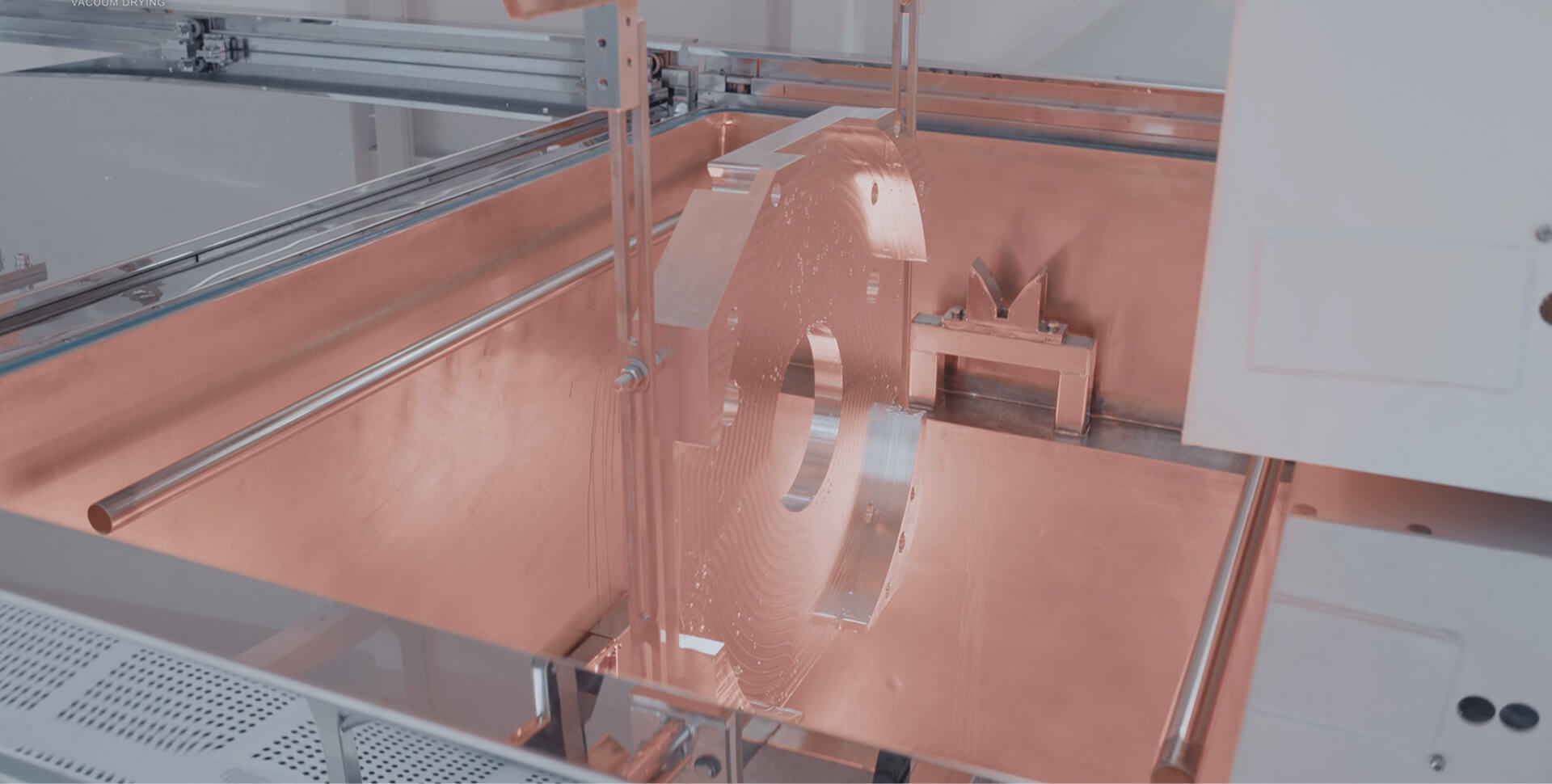

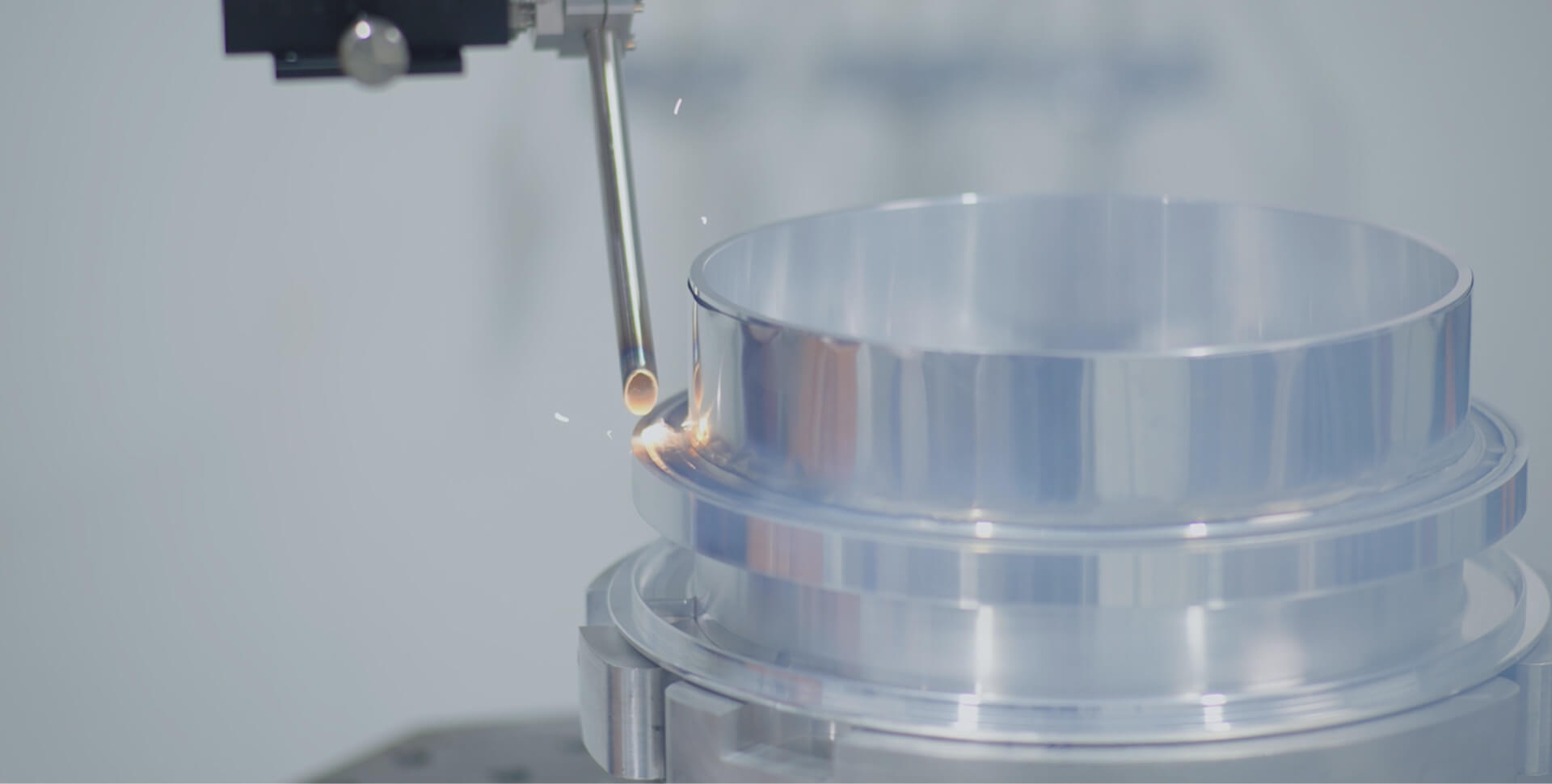

As semiconductor technology continues to evolve, silicon epitaxy processes undergo constant optimization and innovation. Future advancements in silicon epitaxy processes will likely focus on achieving higher purity, larger crystal dimensions, and reduced defect densities to meet the evolving manufacturing requirements of high-performance semiconductor devices. Silicon epitaxy, a critical semiconductor manufacturing process, is essential for enhancing the performance and reliability of semiconductor devices. The Silicon Epitaxy Process Gas Delivery Control Cabinet is an essential component in semiconductor manufacturing, providing a stable gas environment for epitaxial growth through precise control of gas flow, pressure, and purity, thereby ensuring the high quality and uniformity of the resulting epitaxial layer.

Consult an Expert

Consult an Expert

-

Product Features

-

产品参数

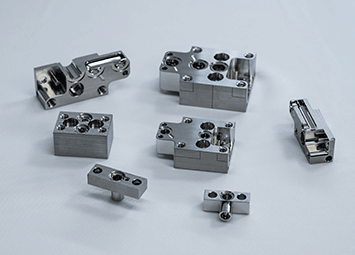

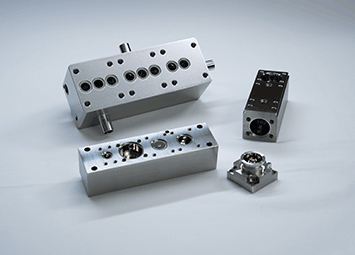

Product Features

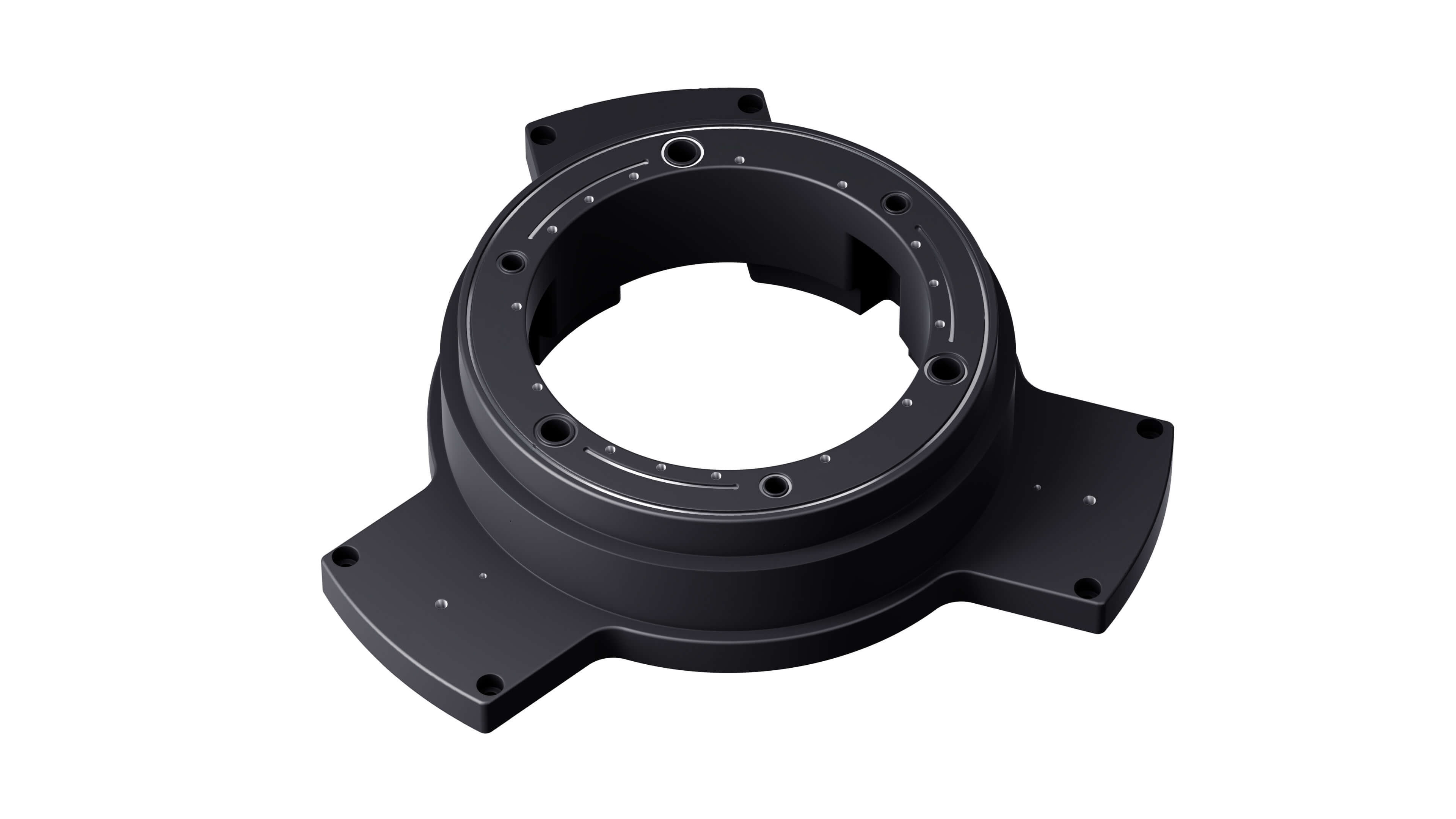

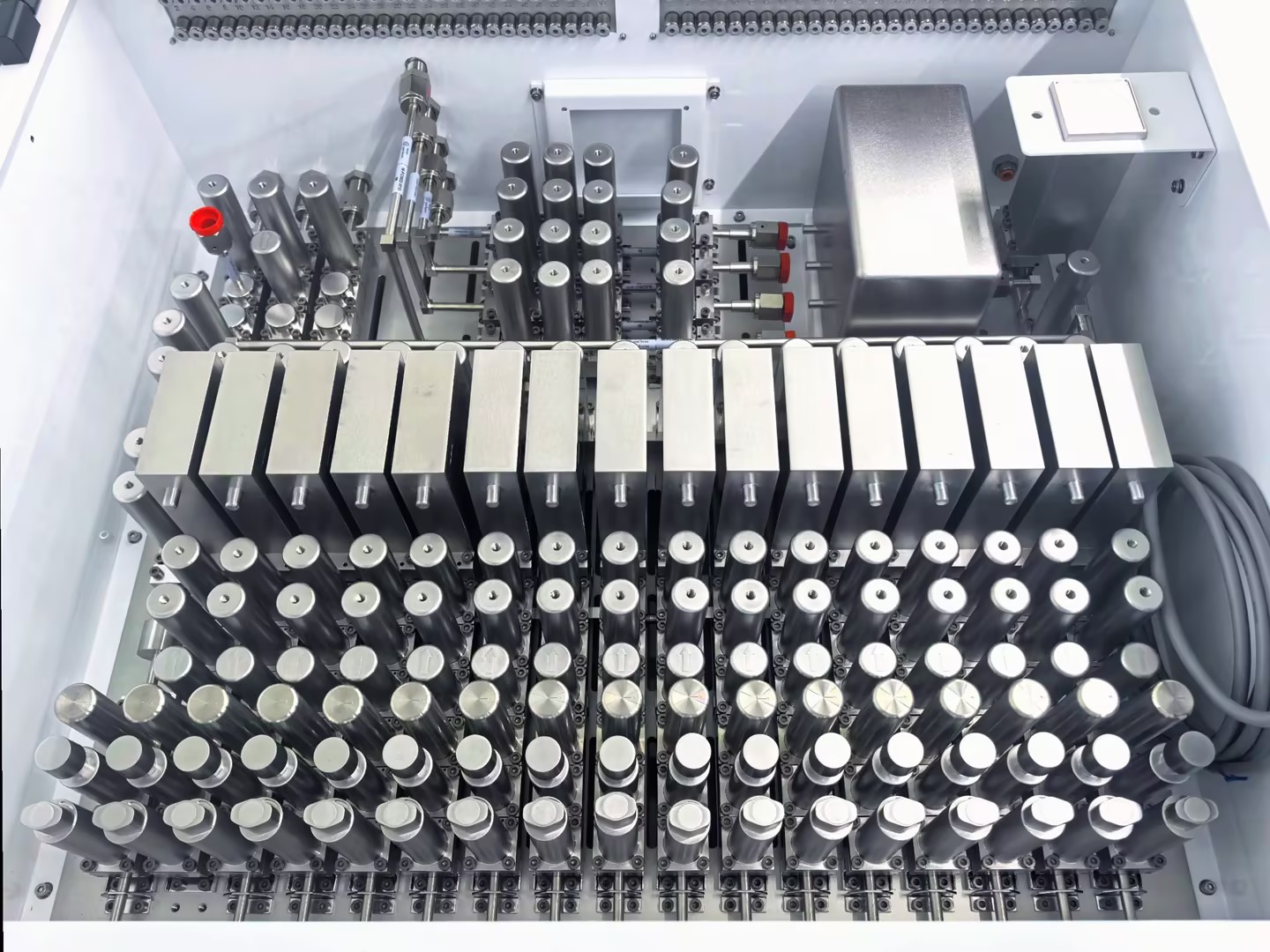

High precision flow control:

High-precision valve systems and flow controllers implement accurate delivery and management of specialty gases, ensuring the stability of critical parameters such as gas flow rate and pressure.

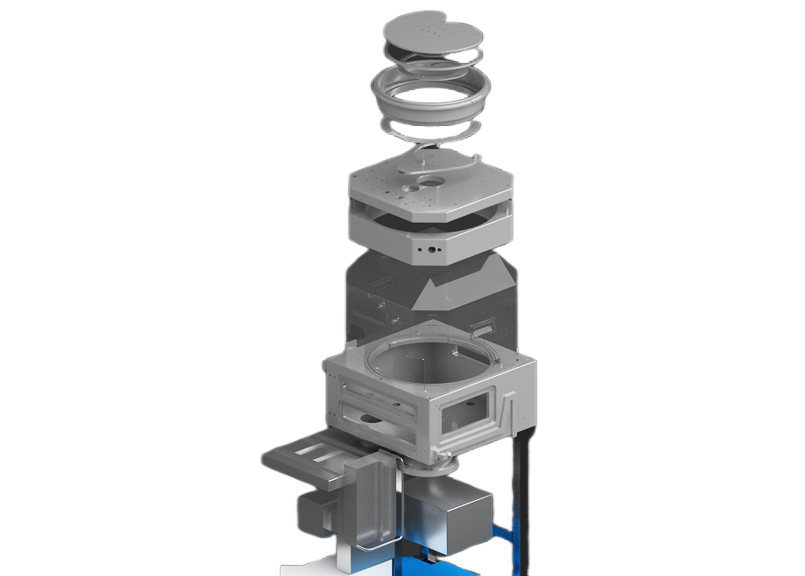

Safety and Stability:

The gas box is equipped with safety components such as door interlock switches, pressure safety switches, check valves, and flame detectors to ensure safety. Simultaneously, the equipment incorporates explosion-proof, corrosion-resistant designs, enhancing safety performance.

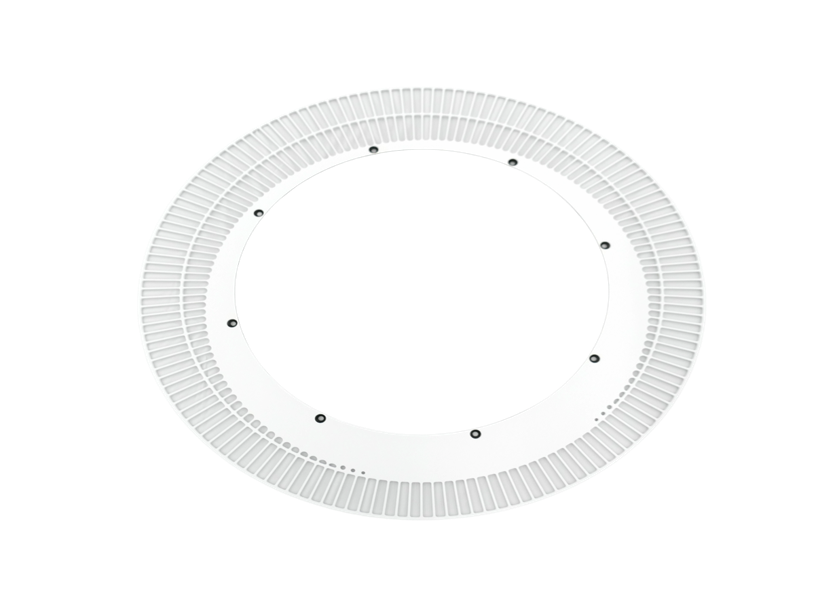

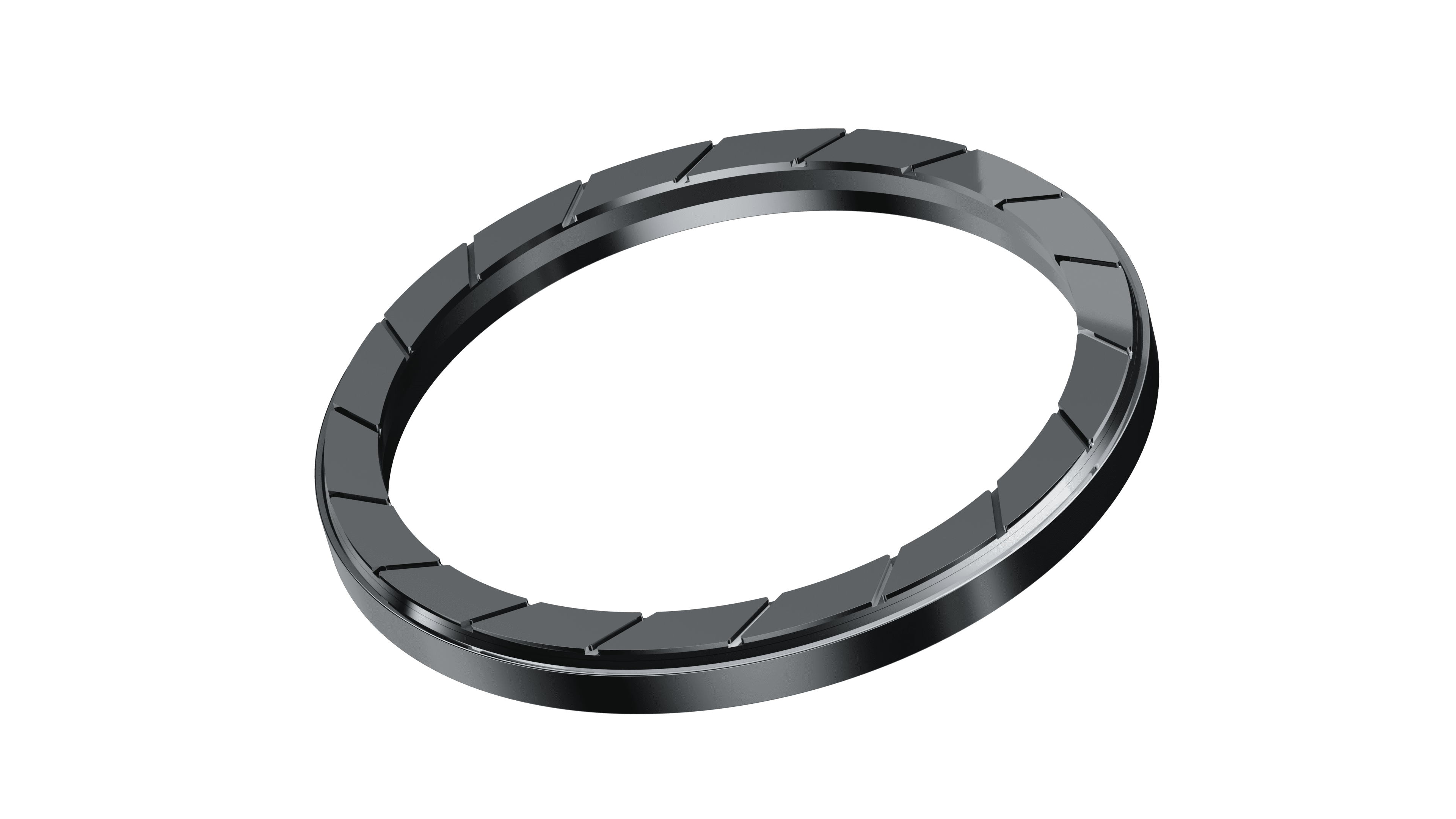

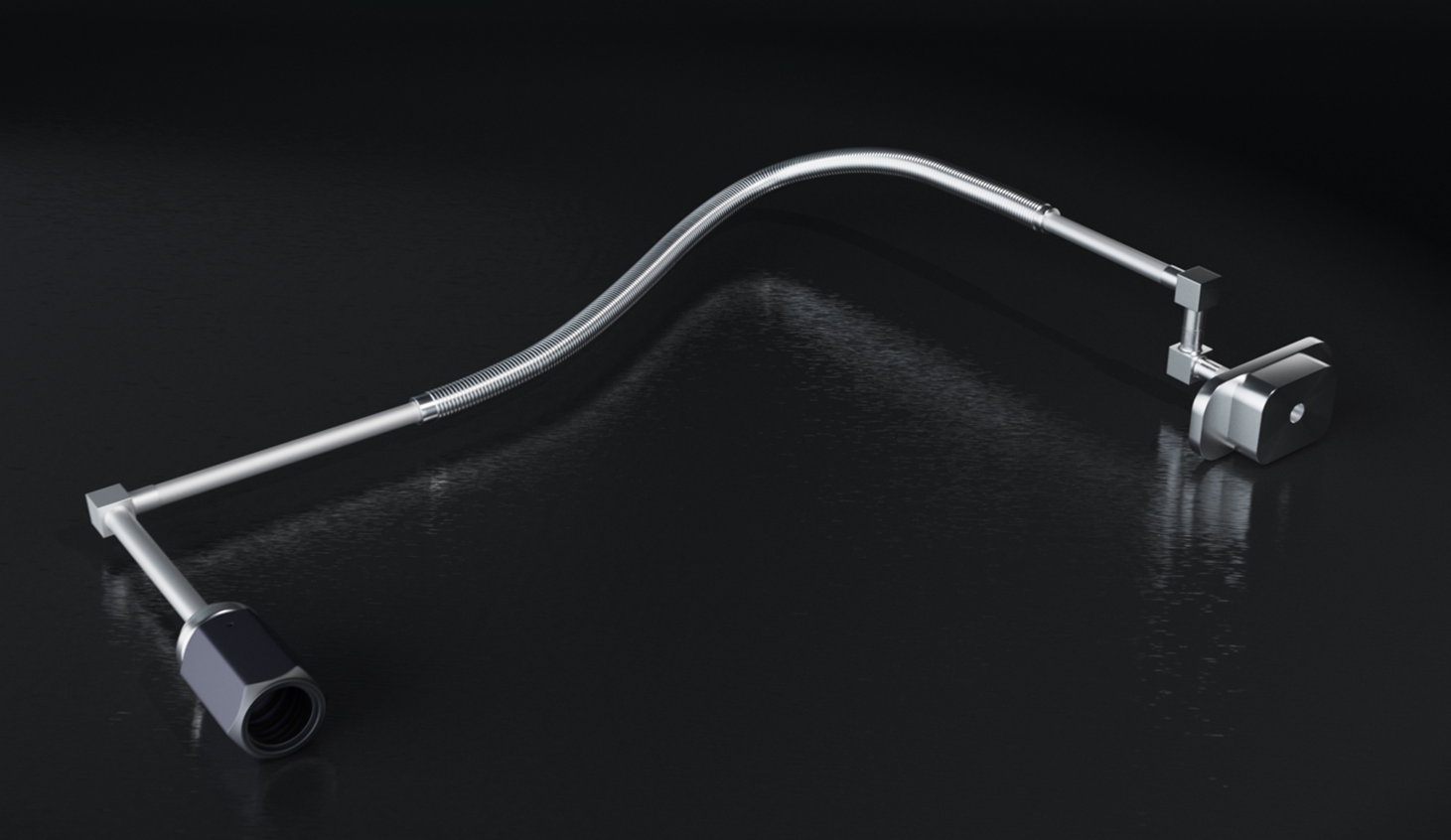

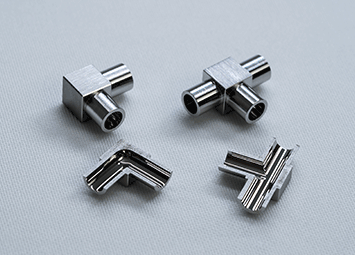

High Airtightness:

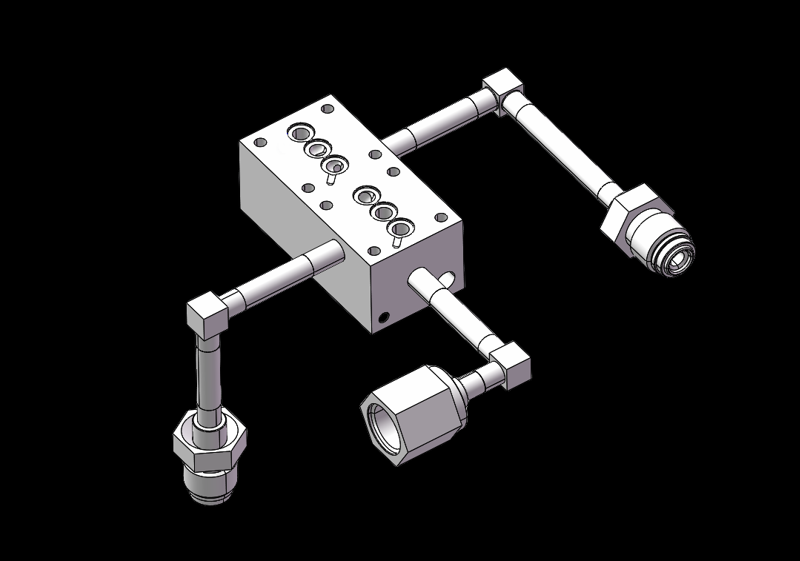

The product utilizes IGS and VCR interface types to achieve high airtightness for semiconductor equipment.

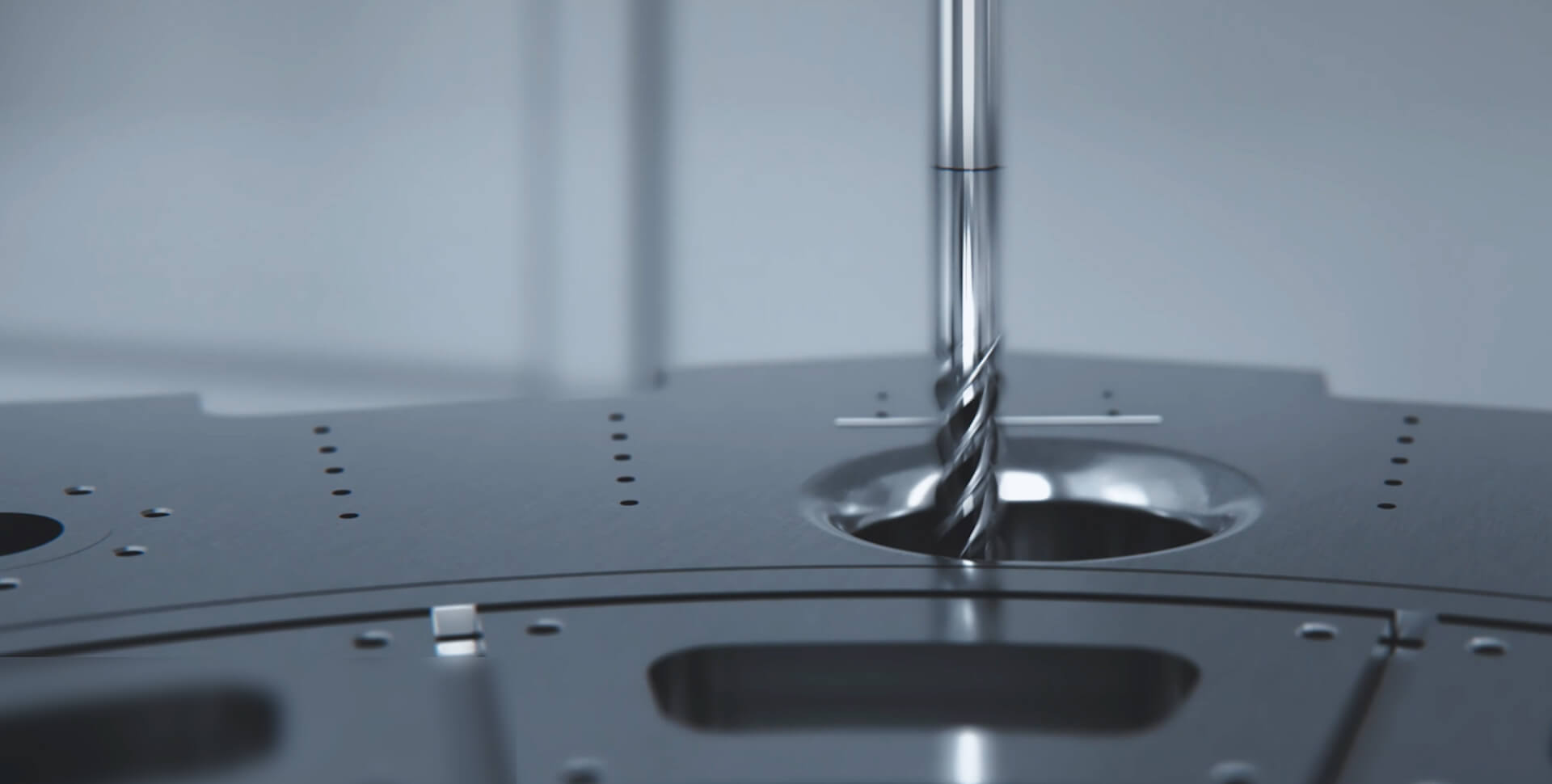

High Cleanliness:

Utilizes high precision filters capable of removing particle impurities larger than 3nm.

Safety Certification:

Passed SEMI S6 safety certification testing.

产品参数

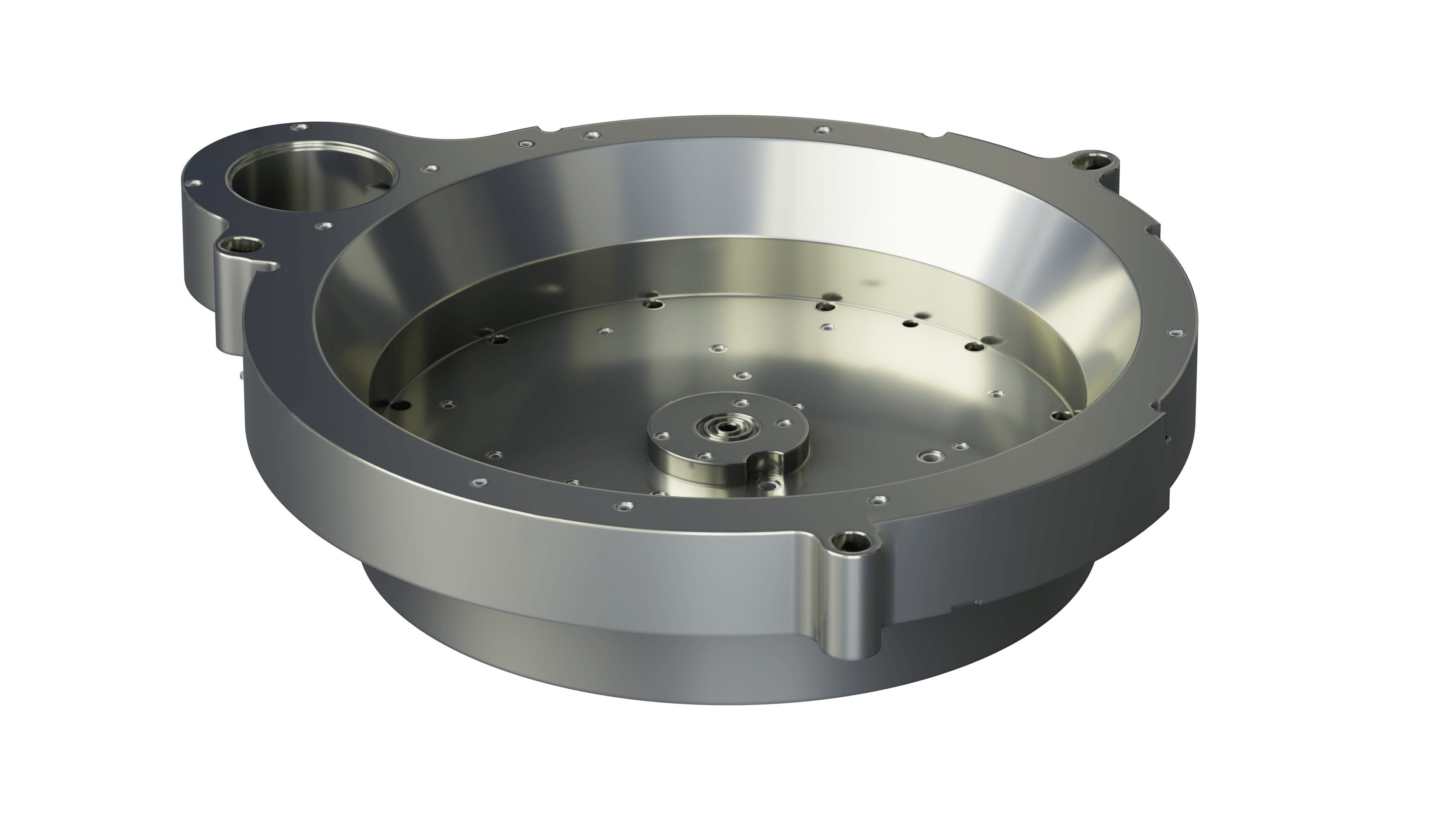

| Outboard leakage rate test: | ≤1.0X10-11/mbar·L/s |

| Inboard leakage rate at seat: | ≤1.0X10-9/mbar·L/s |

| Pressure hold test 50psi: | Nitrogen pressure hold test, hold for 12h, pressure drop ≤1% |

| Helium into a bag leakage rate: | ≤1.0X10-9/mbar·L/s; (Optional) |

| Particle test: | (5 particle @ >0.1um) |

| Moisture and oxygen test: | Moisture content ≤10 PPB, Oxygen content ≤10 PPB; (Optional) |