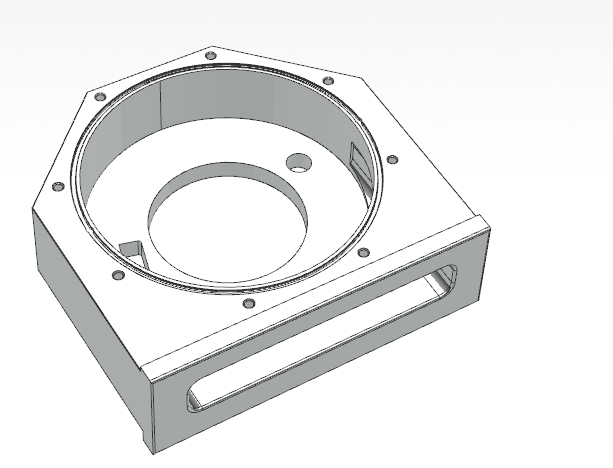

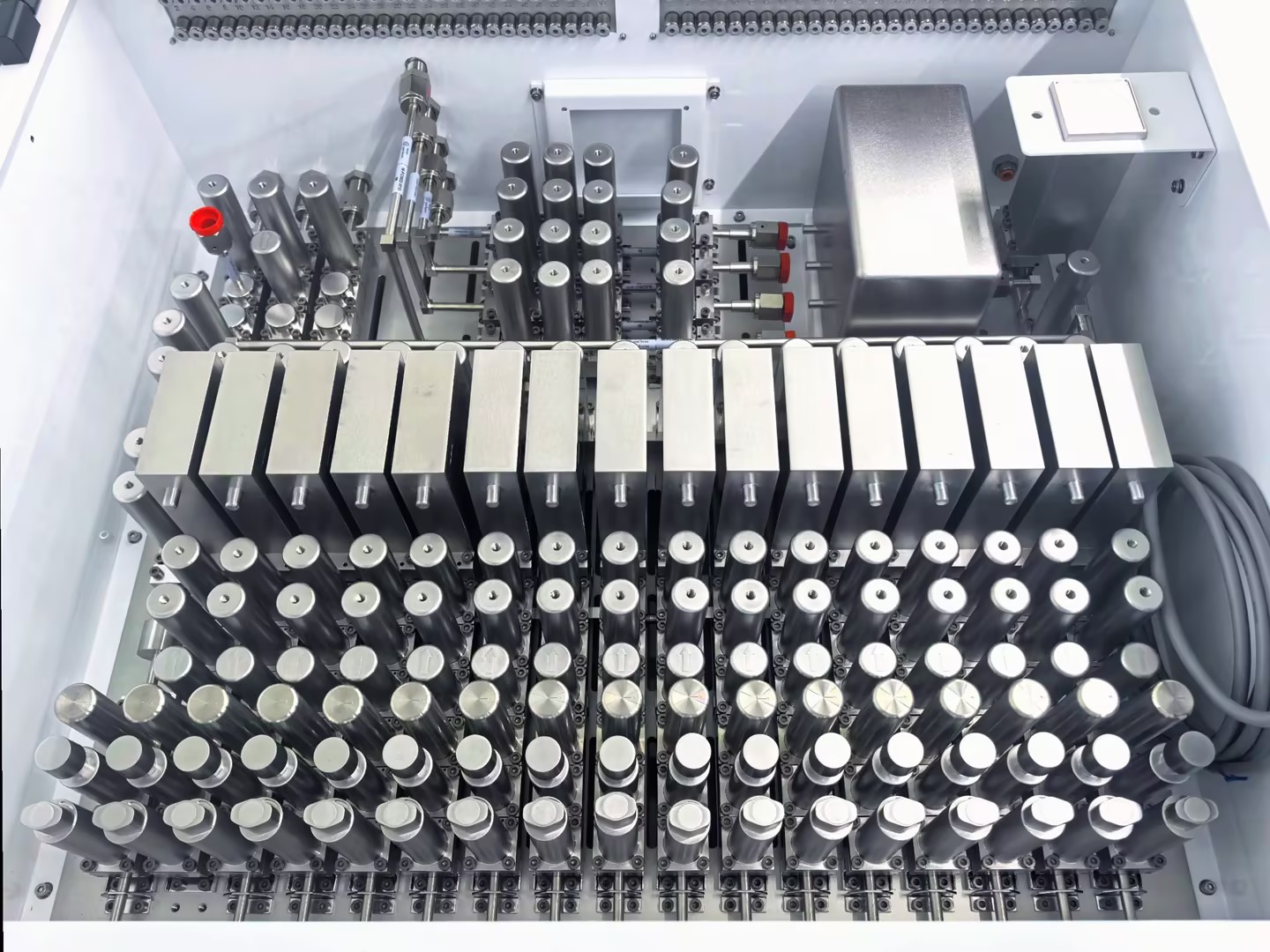

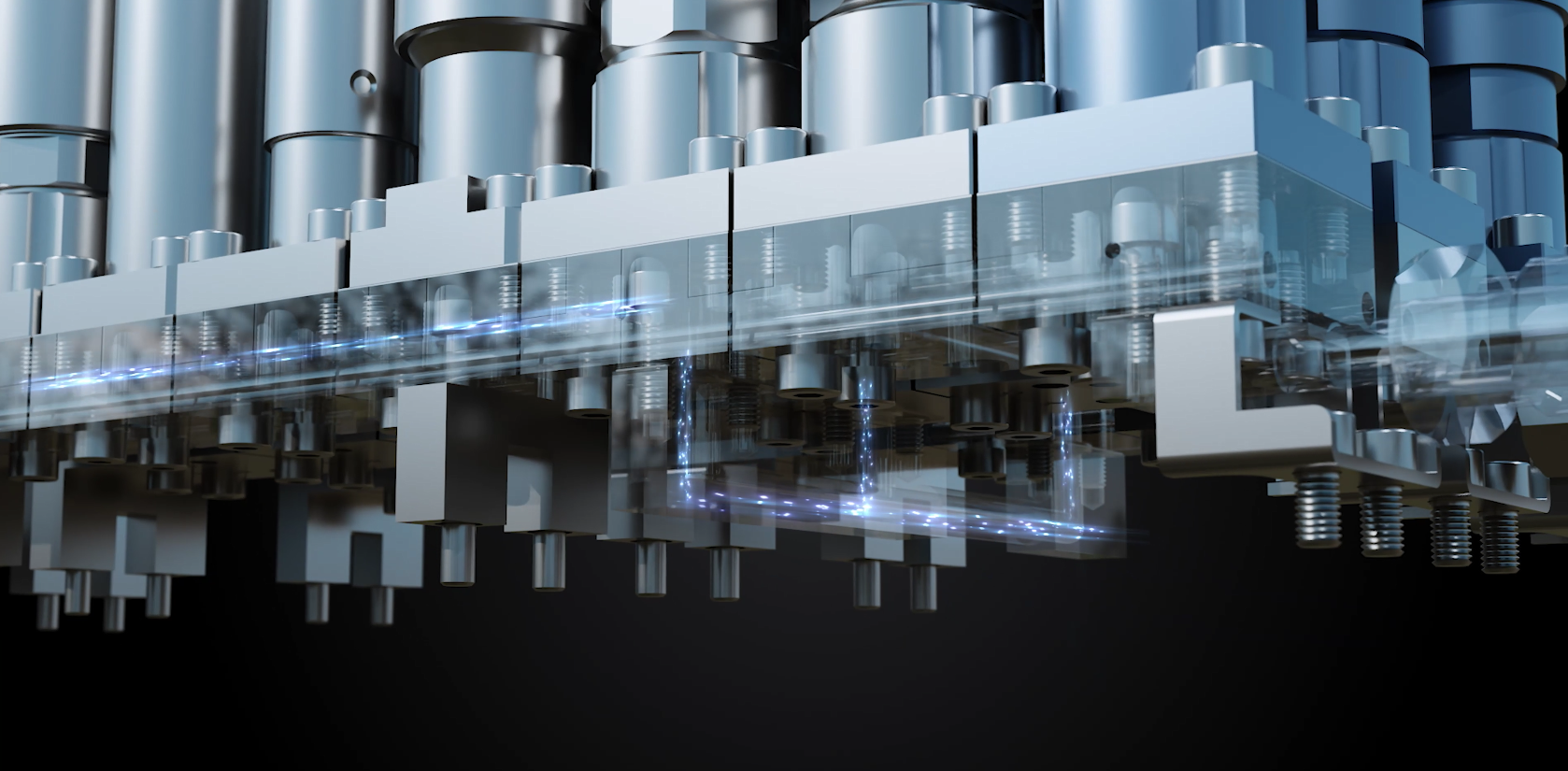

ALD Process GasCabinet

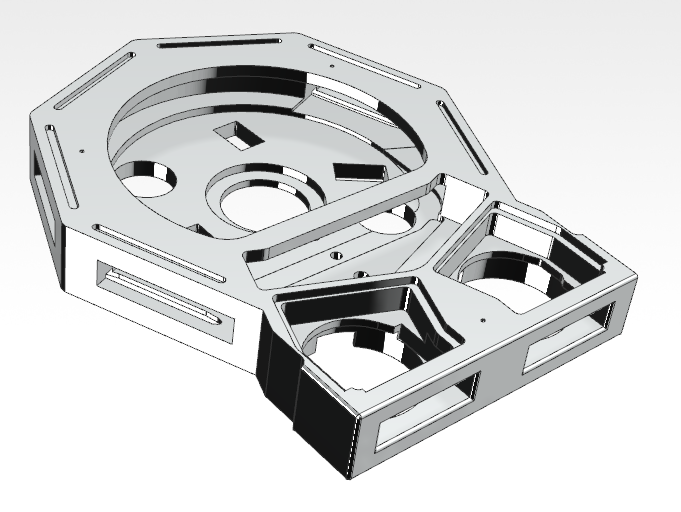

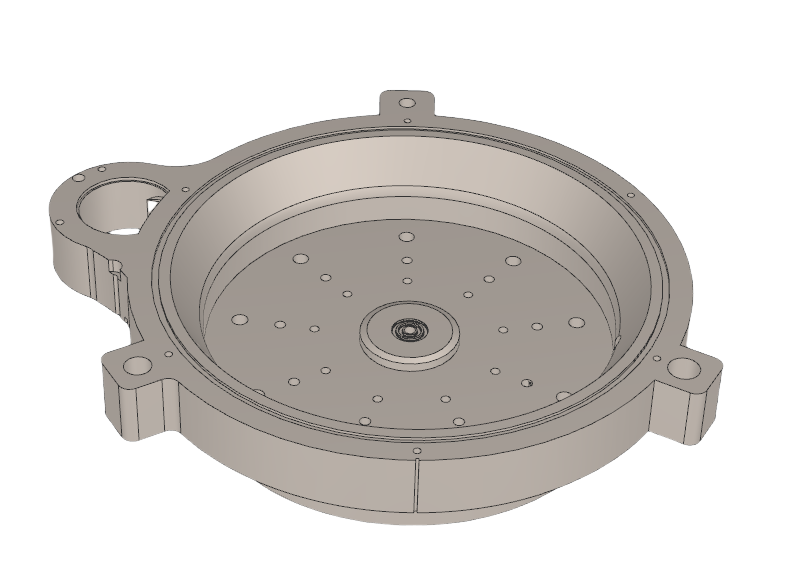

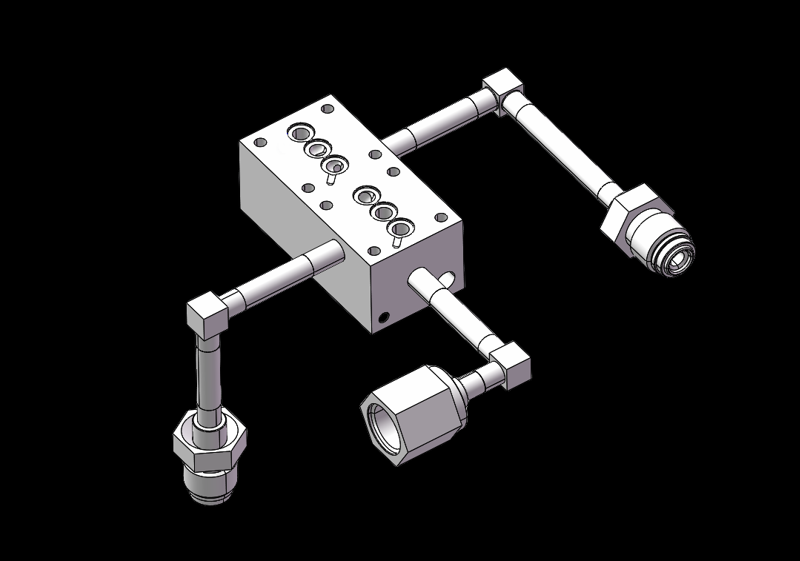

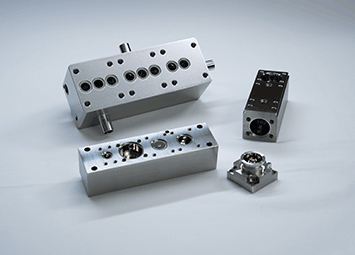

Atomic Layer Deposition (ALD) is a precise thin film deposition technique capable of achieving atomic layer-level precise control and growth on material surfaces at the nanoscale. The ALD Process Gas Delivery Control Cabinet is equipment specifically used during the ALD process to ensure stable, precise, and safe gas transmission. This control cabinet uses high precision control to guarantee accurate regulation of gas flow, pressure, and temperature, meeting the strict requirements of the ALD process for gas supply.

Consult an Expert

Consult an Expert

-

Product Features

-

Product Parameters

Product Features

High precision flow control:

Precise control of reactant gas introduction into the reaction chamber is achieved through the use of high precision gas mass flow controllers, ensuring stable process conditions.

Rapid gas switching is achieved through the implementation of fast-acting pneumatic valves, thereby ensuring process stability.

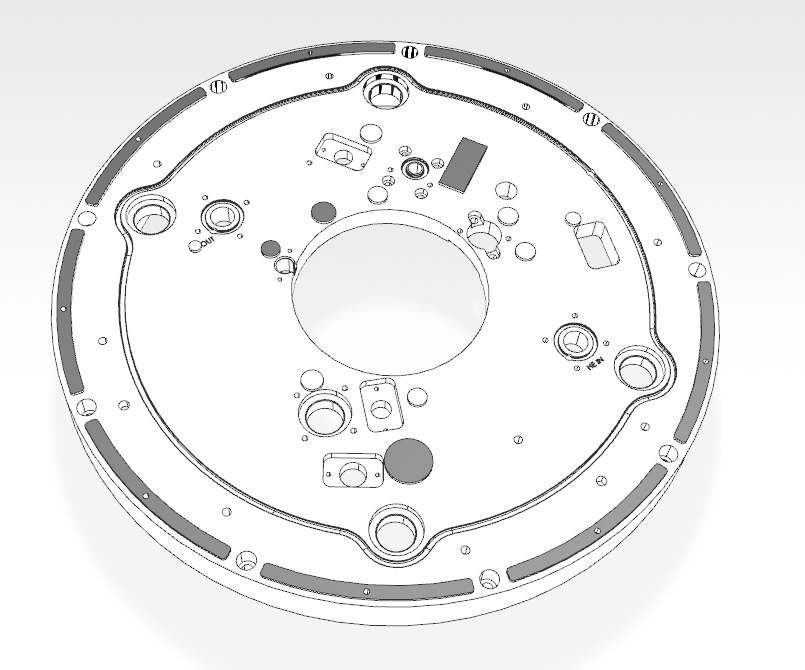

Safety and Stability:

The gas box is equipped with safety components such as door interlock switches, pressure safety switches, and check valves to ensure safety.

Simultaneously, the equipment incorporates explosion-proof, corrosion-resistant designs, enhancing safety performance.

High Airtightness:

The product utilizes IGS and VCR interface types to achieve high airtightness for semiconductor equipment.

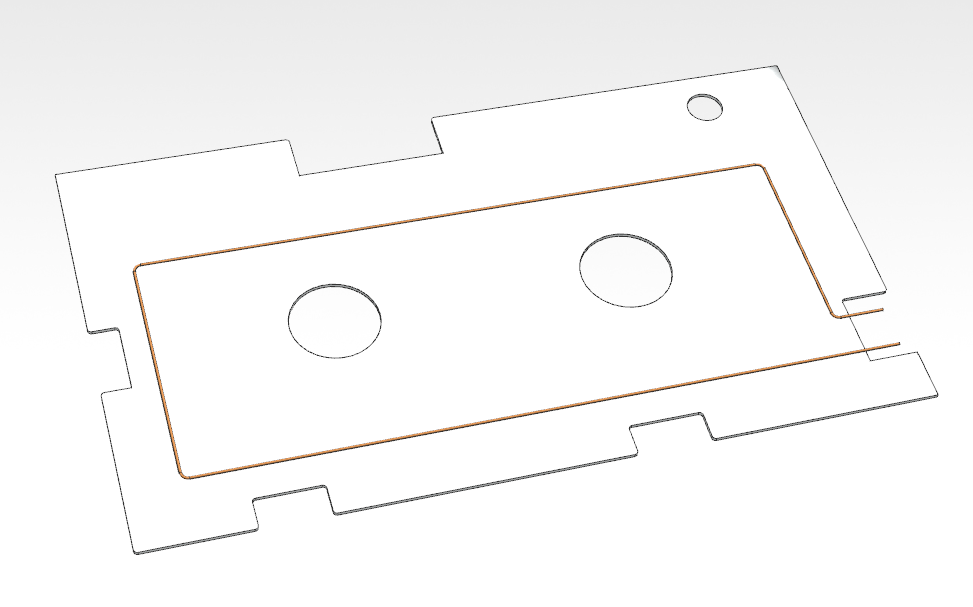

High Cleanliness:

High precision filters are employed to remove particle contaminants exceeding 3 nm in diameter.

Safety Certification:

Passed SEMI S6 safety certification testing.

Product Parameters

| Outboard leakage rate test: | ≤1.0X10-11/mbar·L/s |

| Inboard leakage rate at seat: | ≤1.0X10-9/mbar·L/s |

| Pressure hold test 50psi: | Nitrogen pressure hold test, hold for 12h, pressure drop ≤1% |

| Helium into a bag leakage rate: | ≤1.0X10-9/mbar·L/s;(Optional) |

| Particle test: | (5 particle @ >0.1um) |

| Moisture and oxygen test: | Moisture content ≤10 PPB, Oxygen content ≤10 PPB; (Optional) |