Technology

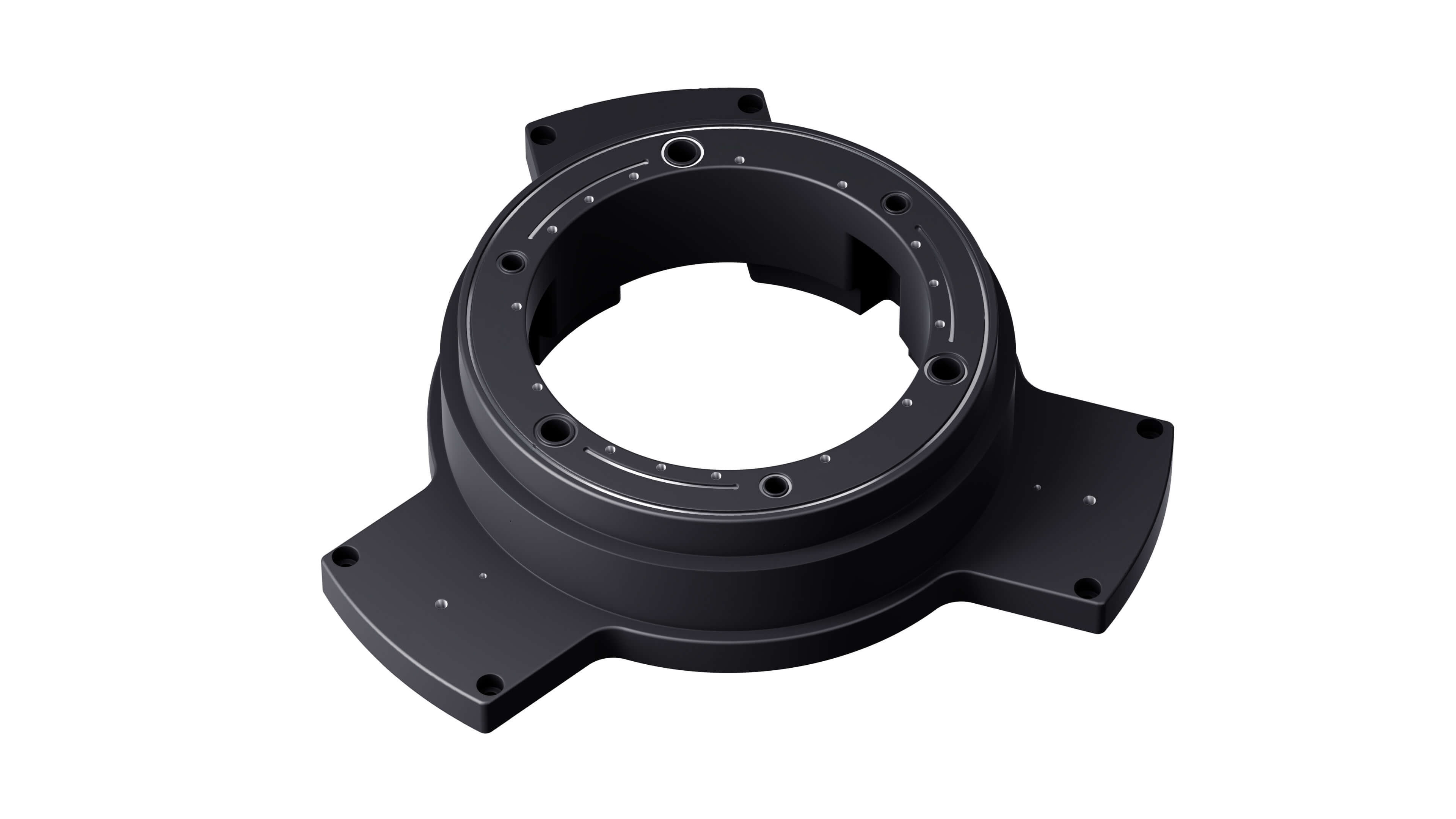

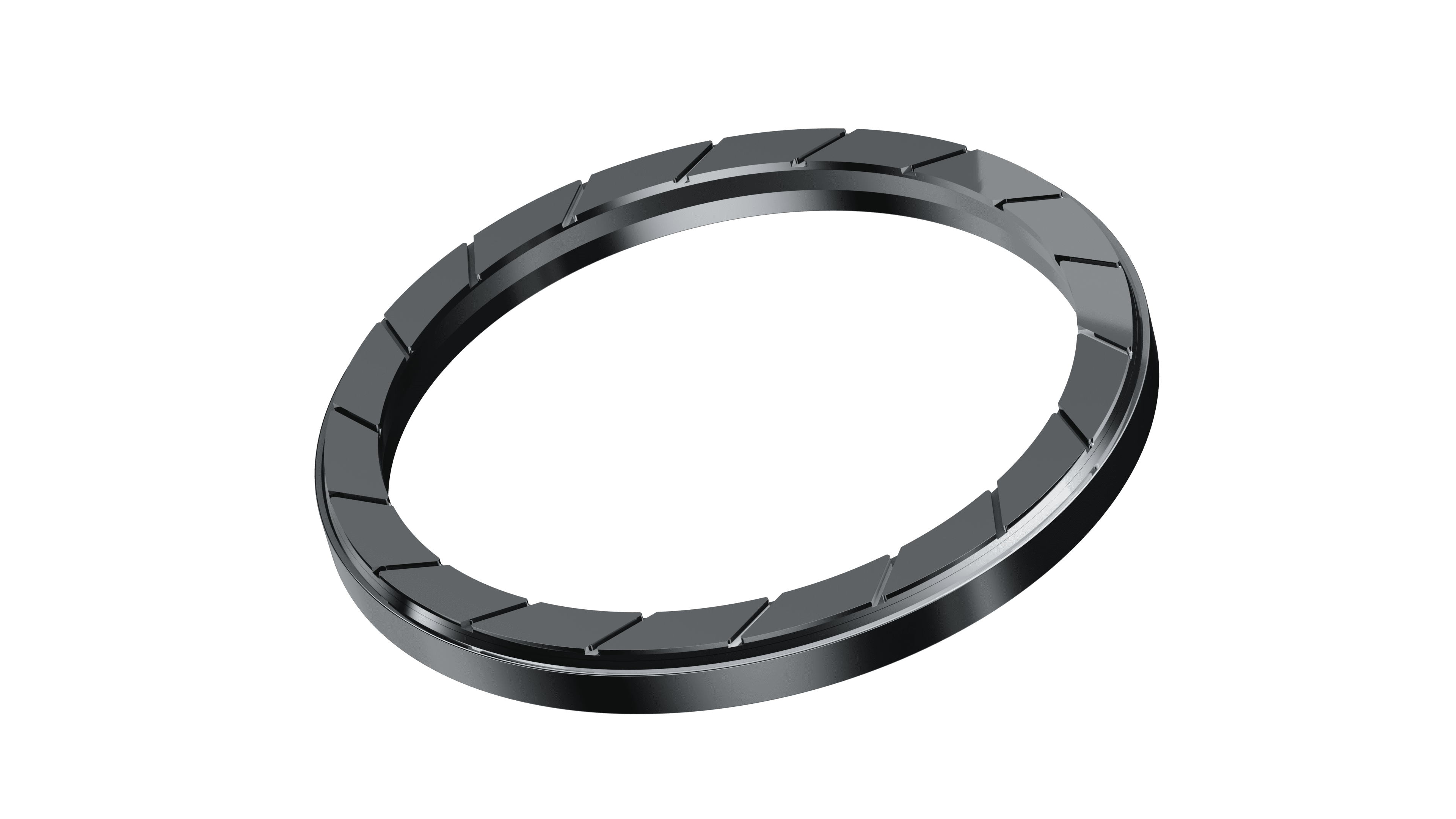

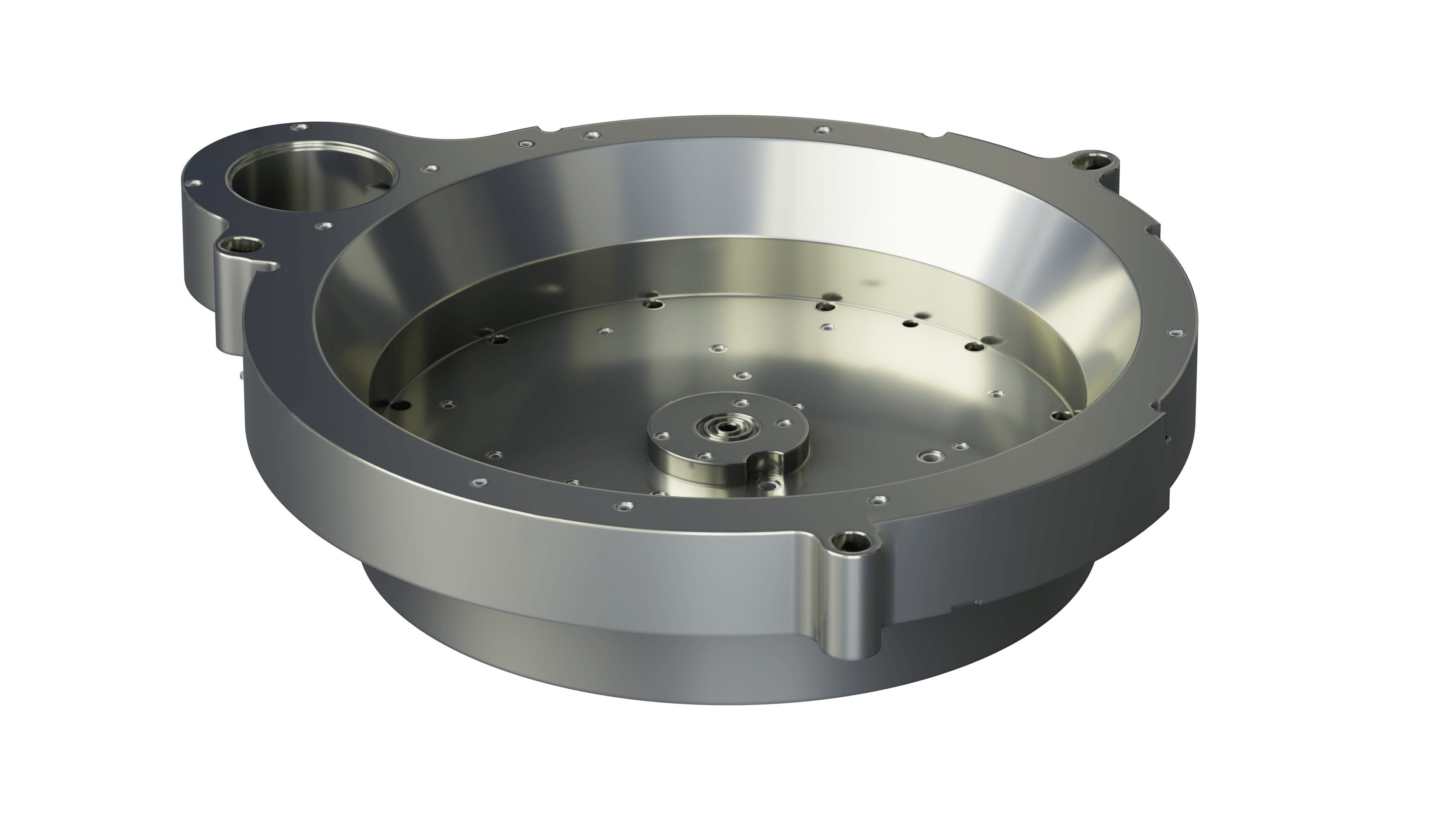

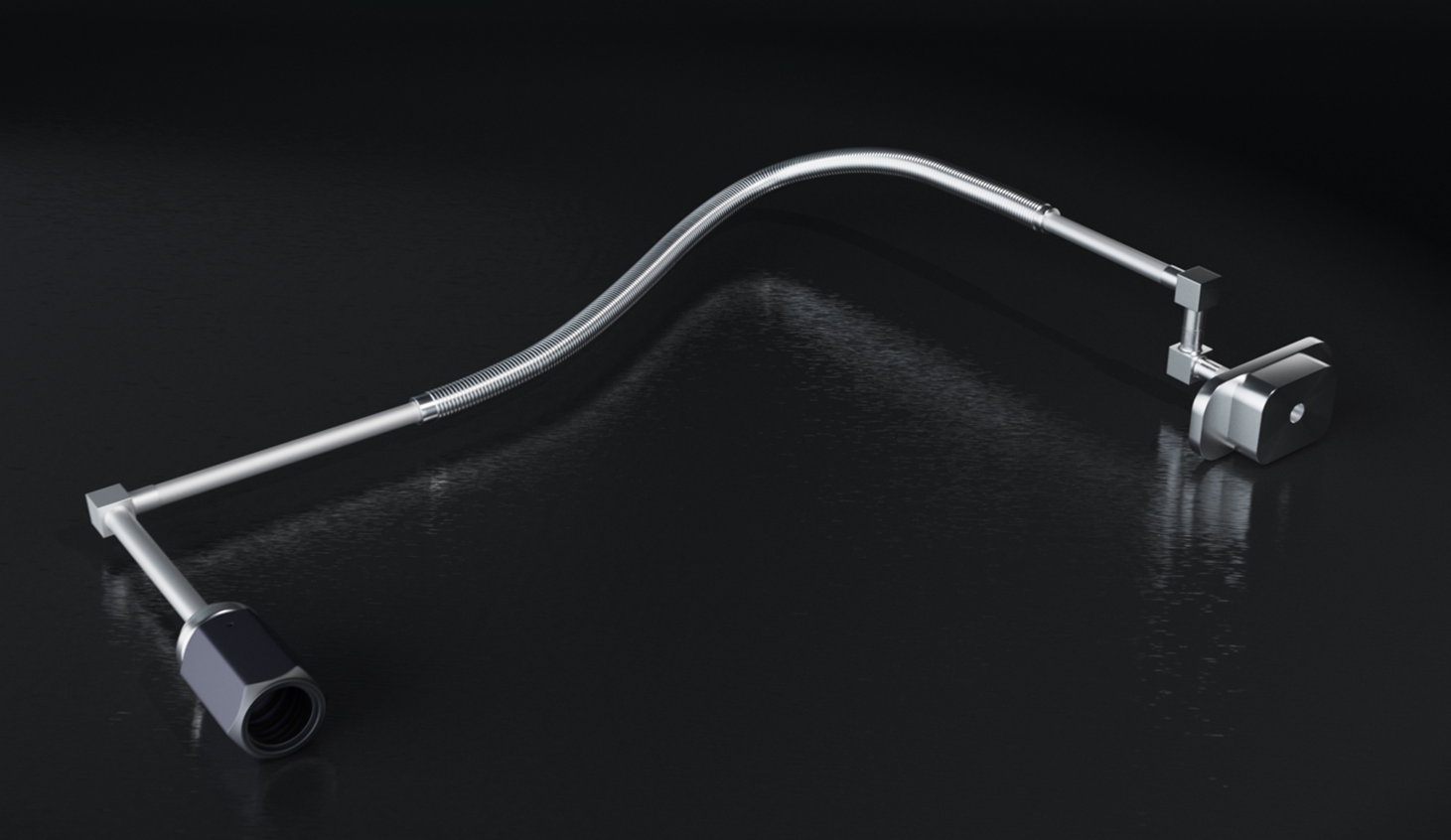

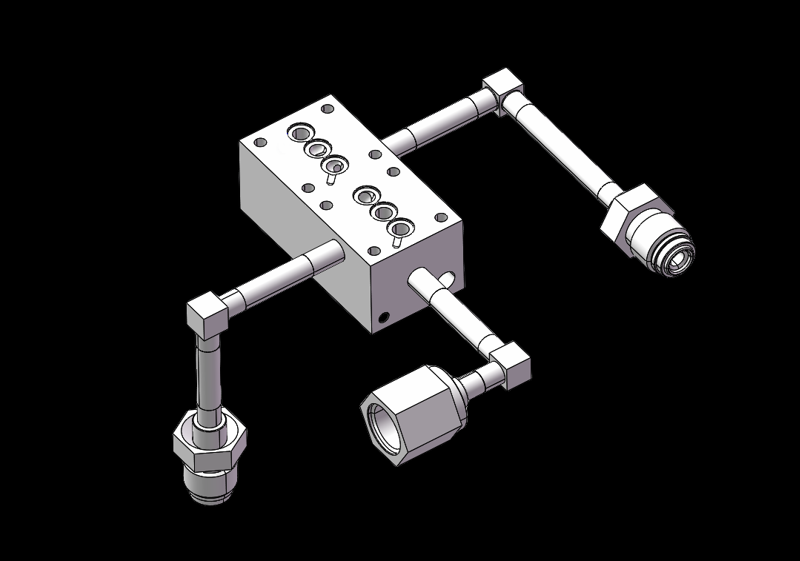

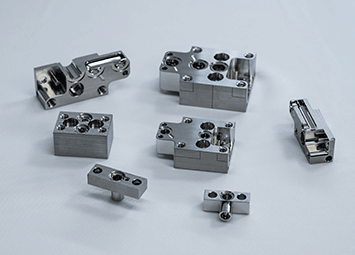

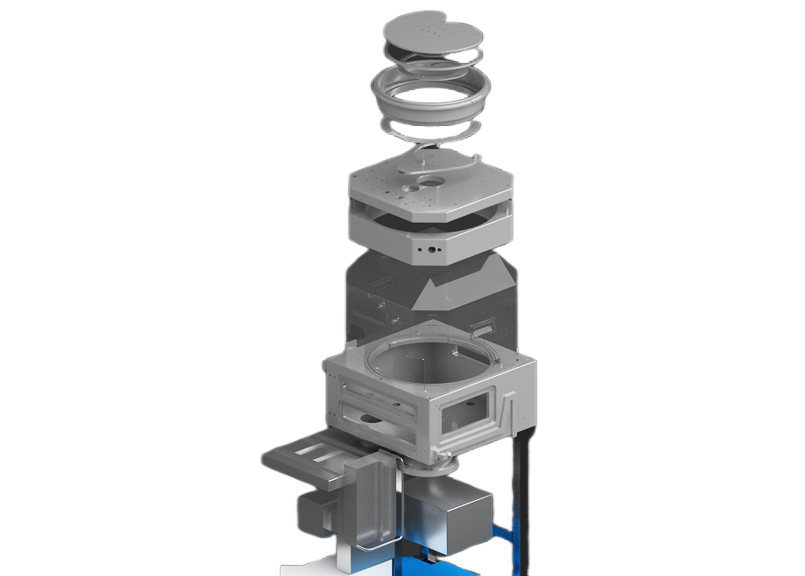

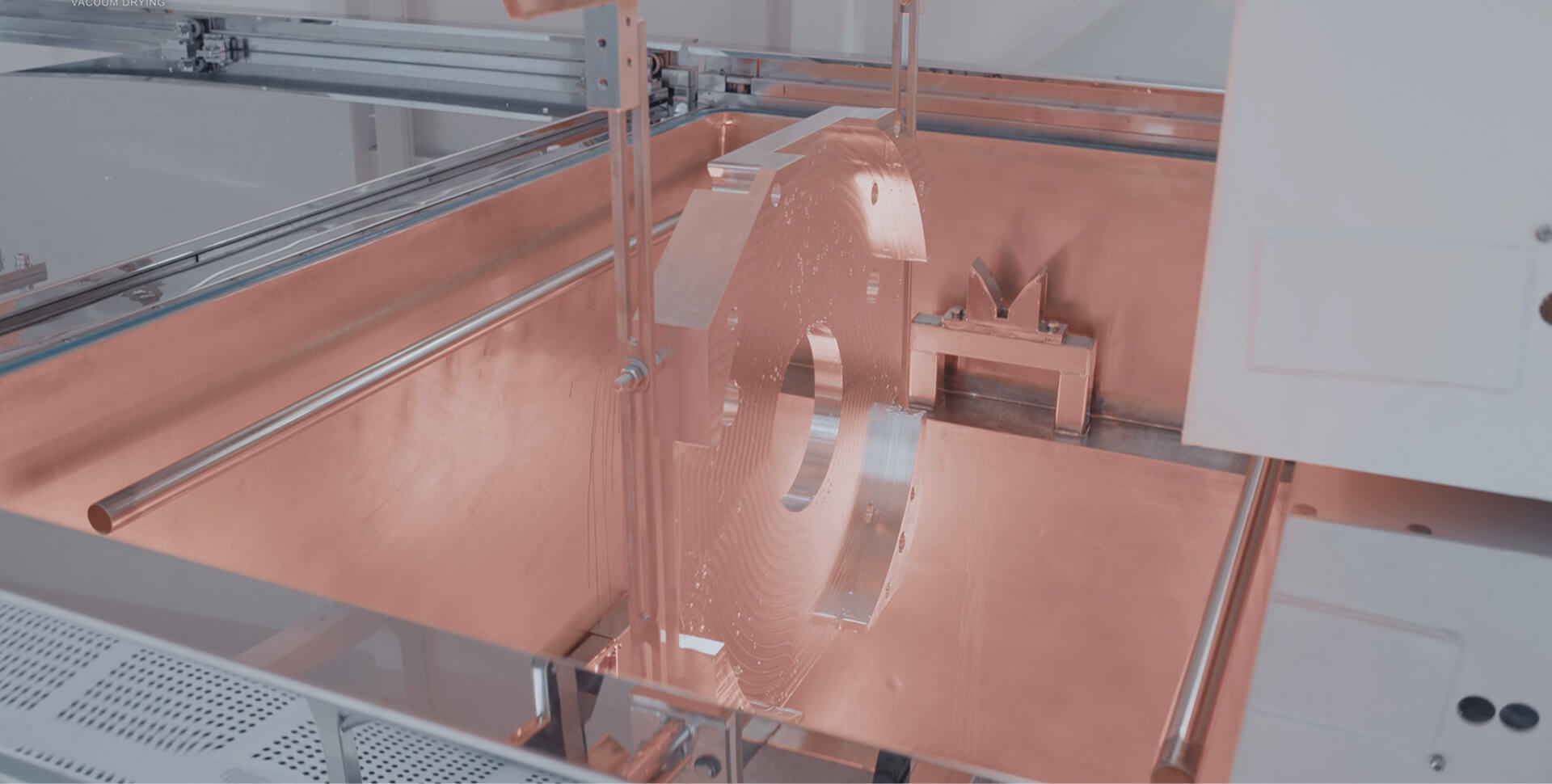

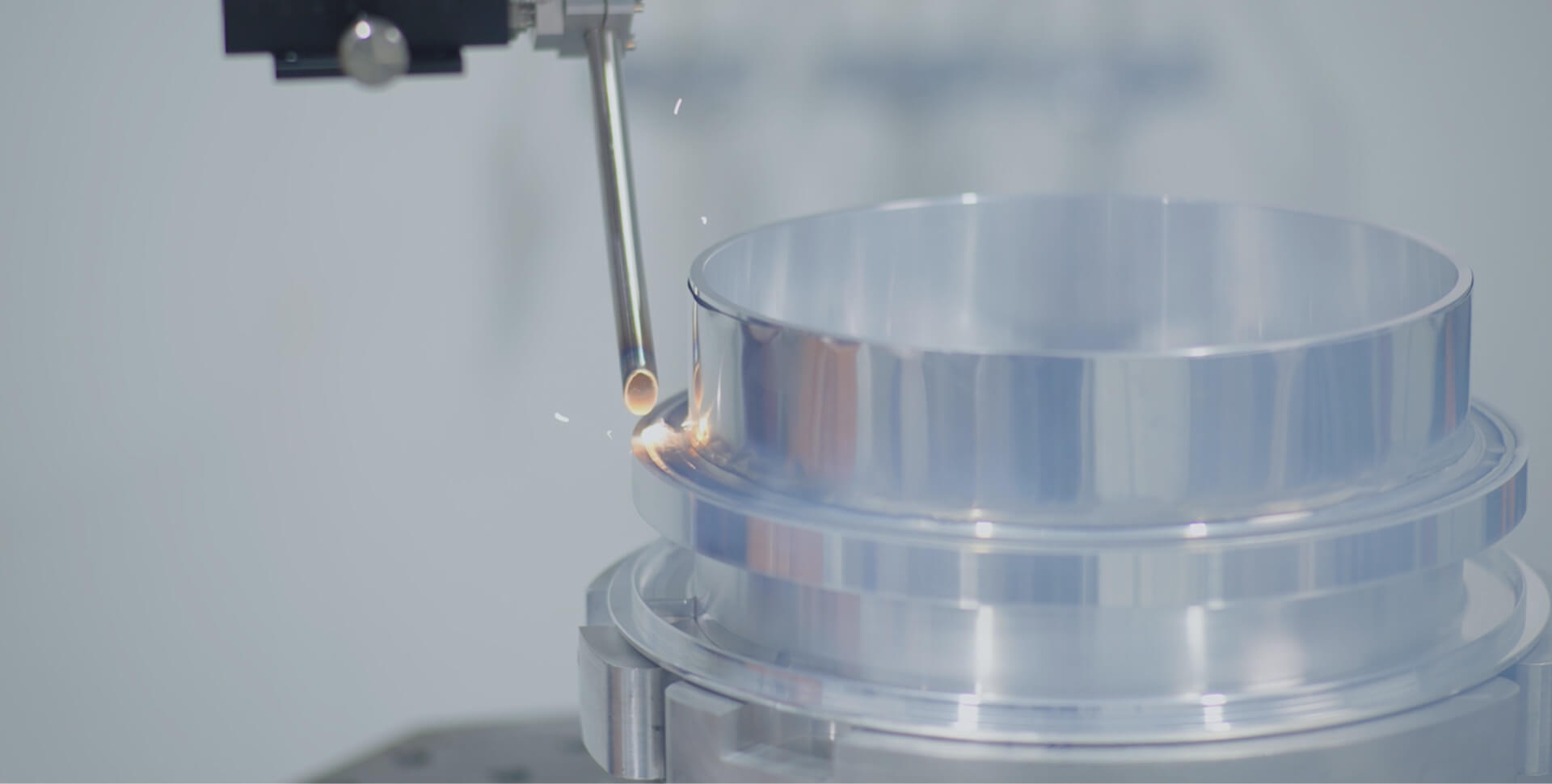

Stainless Steel Ultra-High Surface Finish Stainless Steel Manufacturing Technology

Employing self-designed tooling in conjunction with precision machining technology such as drilling, milling, and reaming, this technology achieves the stringent surface roughness and hardness specifications required for flow channels, functional surfaces, and sealing surfaces.

Following machining, stainless steel mirror polishing technology is utilized to improve wetted surface roughness, enabling high-quality, high-efficiency mirror polishing even on complex features.

The product's wetted surface roughness meets SEMI standards and surpasses the stringent requirements of leading international clients, enabling laminar gas flow with minimal turbulence to achieve rapid gas delivery response and corrosion resistance.

Learn more

Learn more

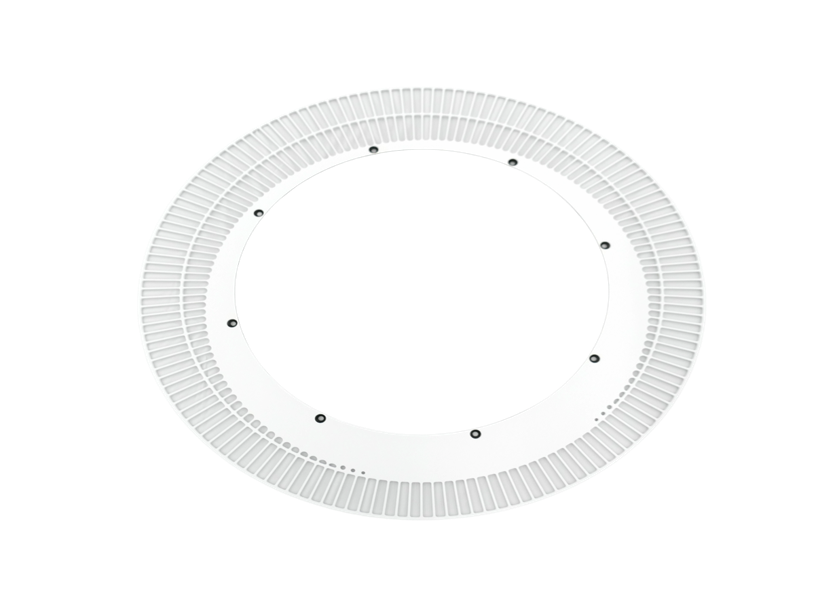

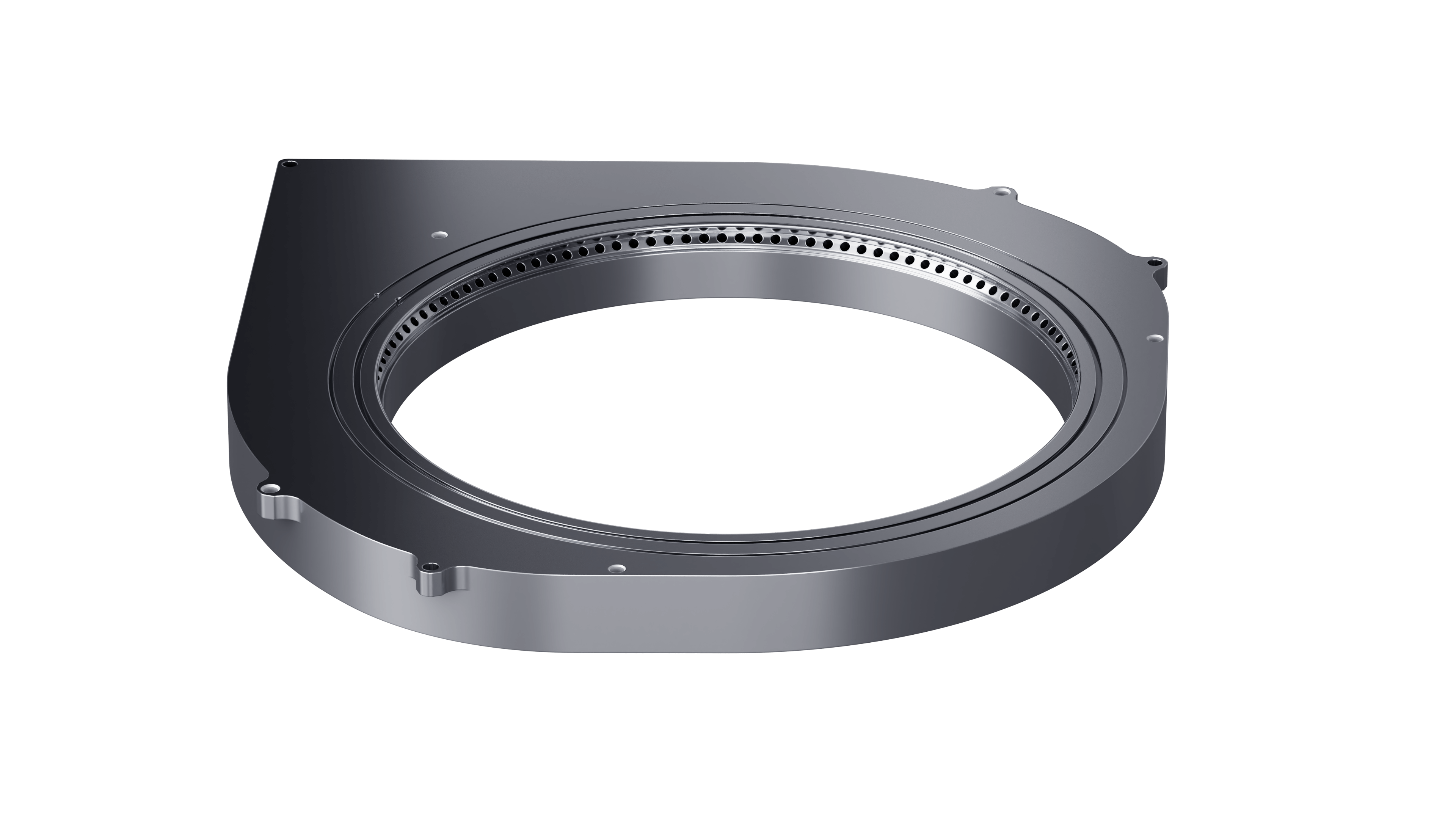

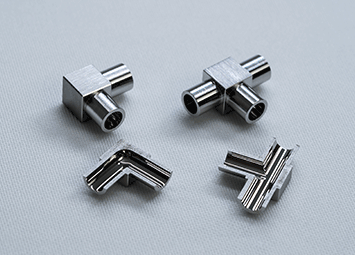

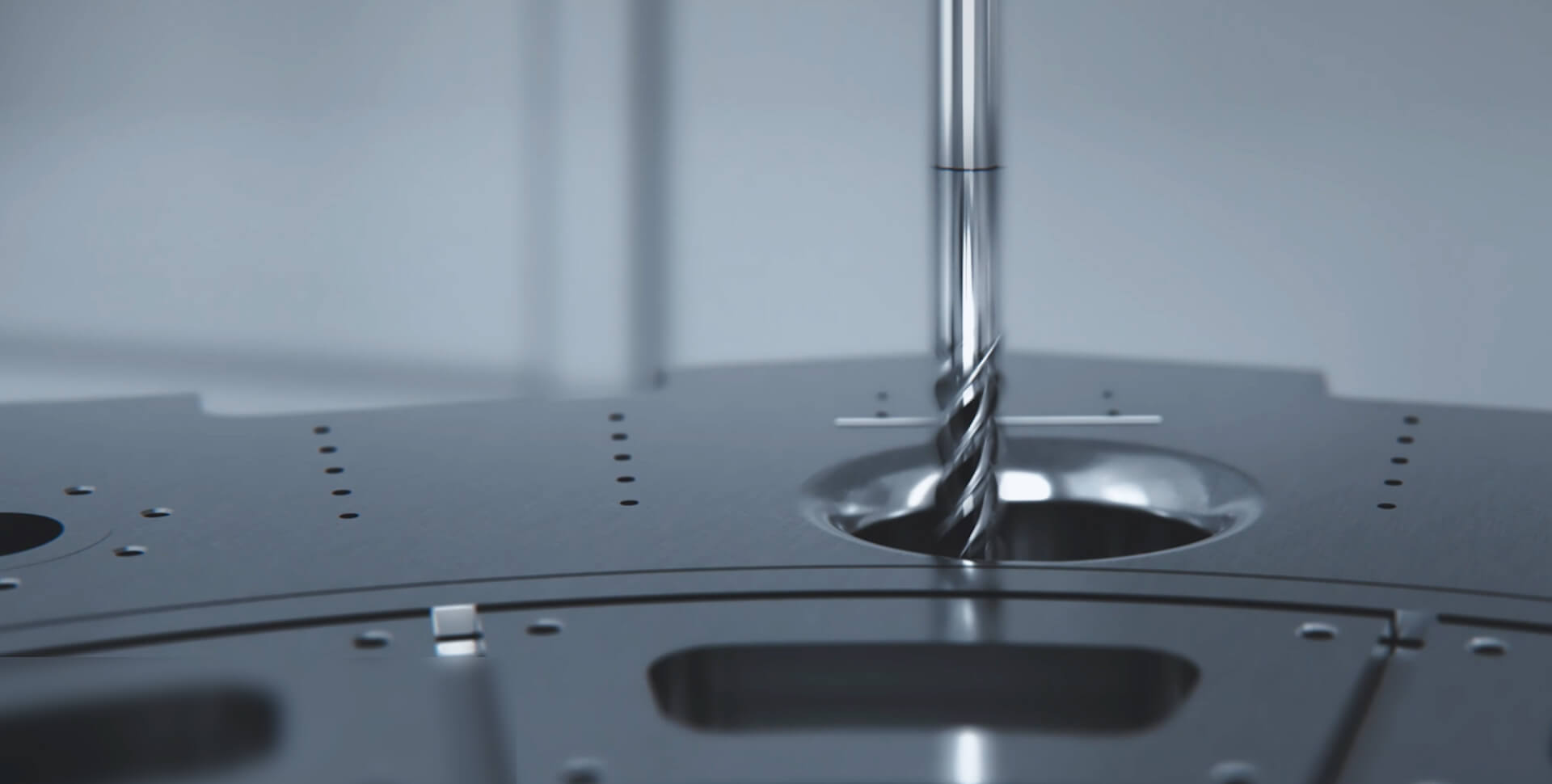

High Precision Micro-Hole Manufacturing Technology

Micro-hole fabrication is achieved through precise material control and processing. This technology also enables control over hole shape, size, and surface quality, thus meeting the requirements of diverse applications.

Professional high-speed drilling machines and AOI (Automated Optical Inspection) equipment for micro-hole processing and inspection.

Learn more

Learn more

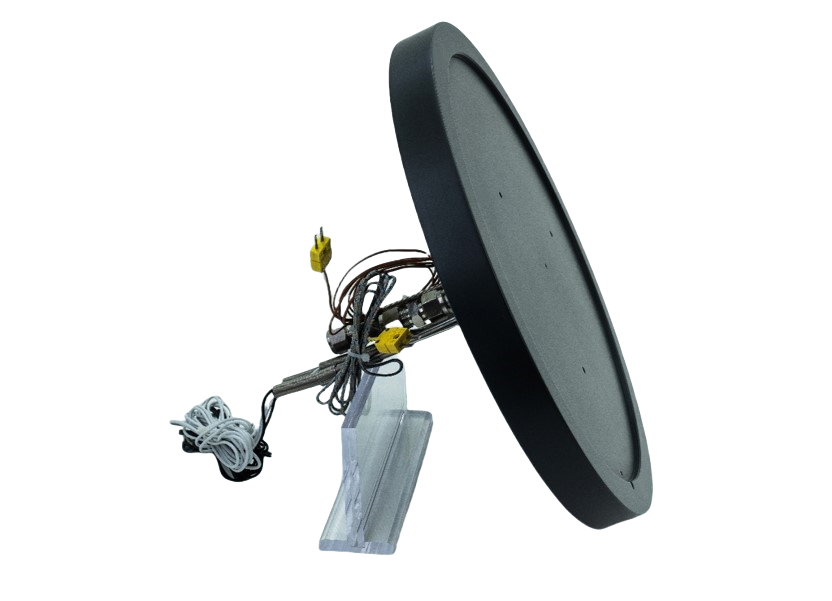

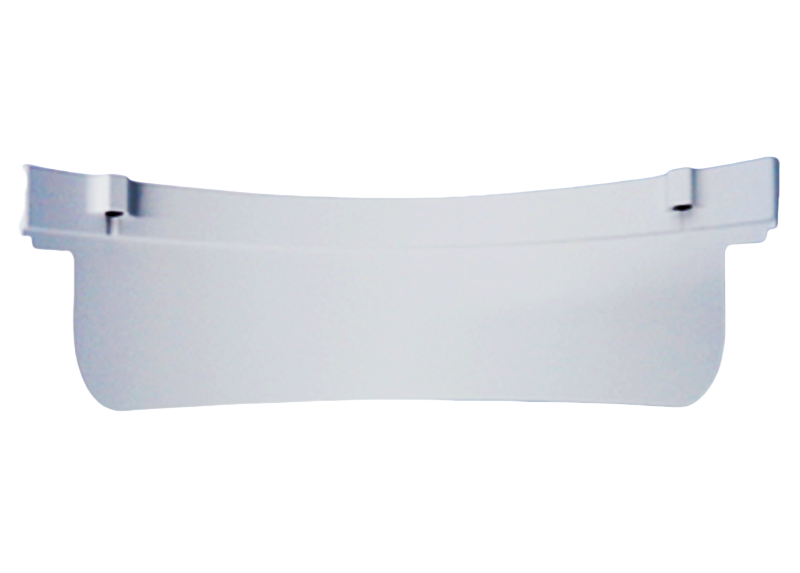

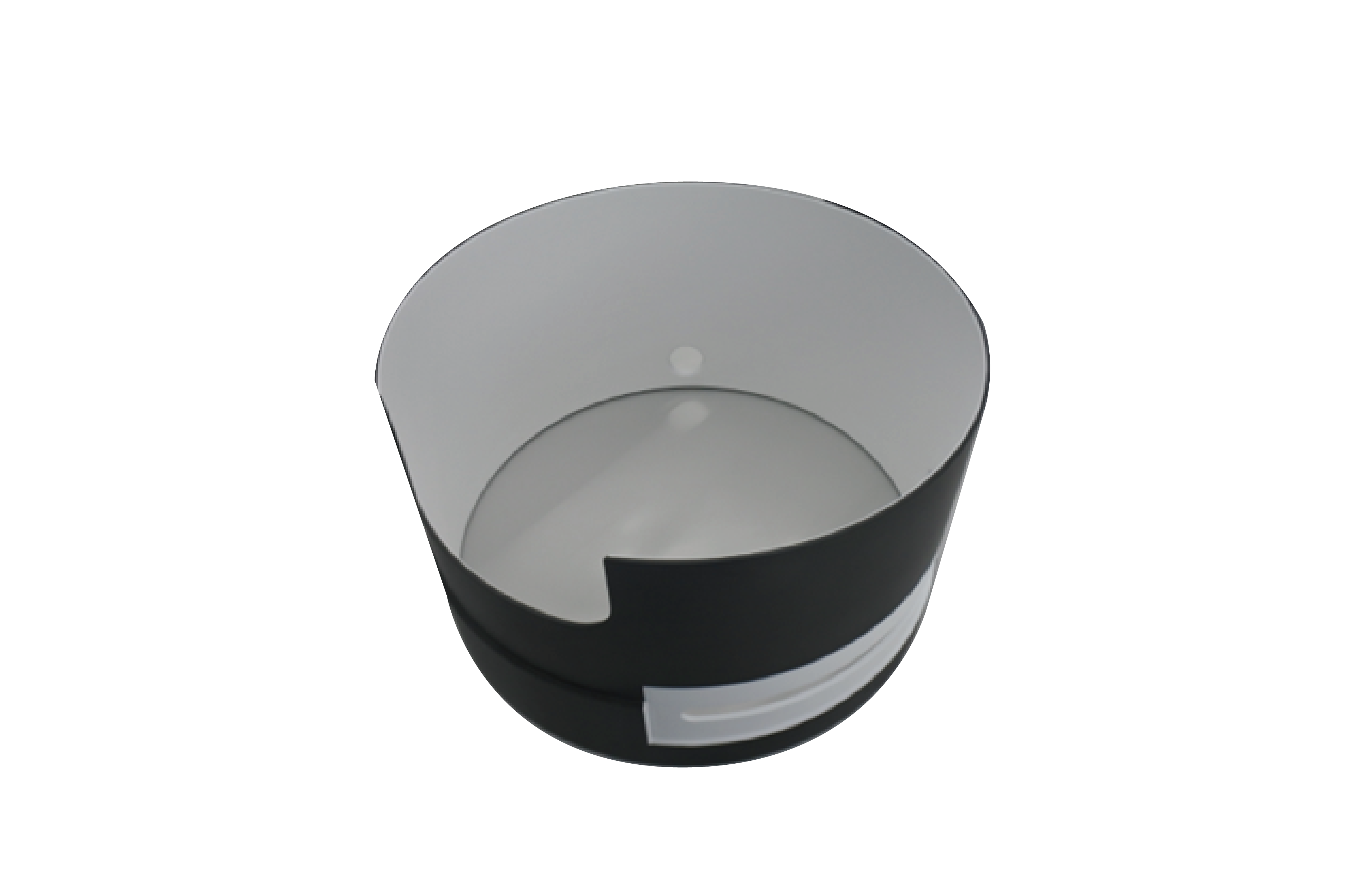

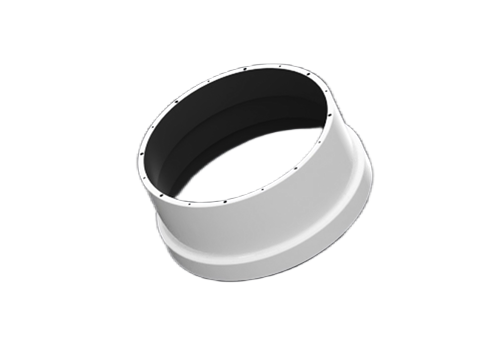

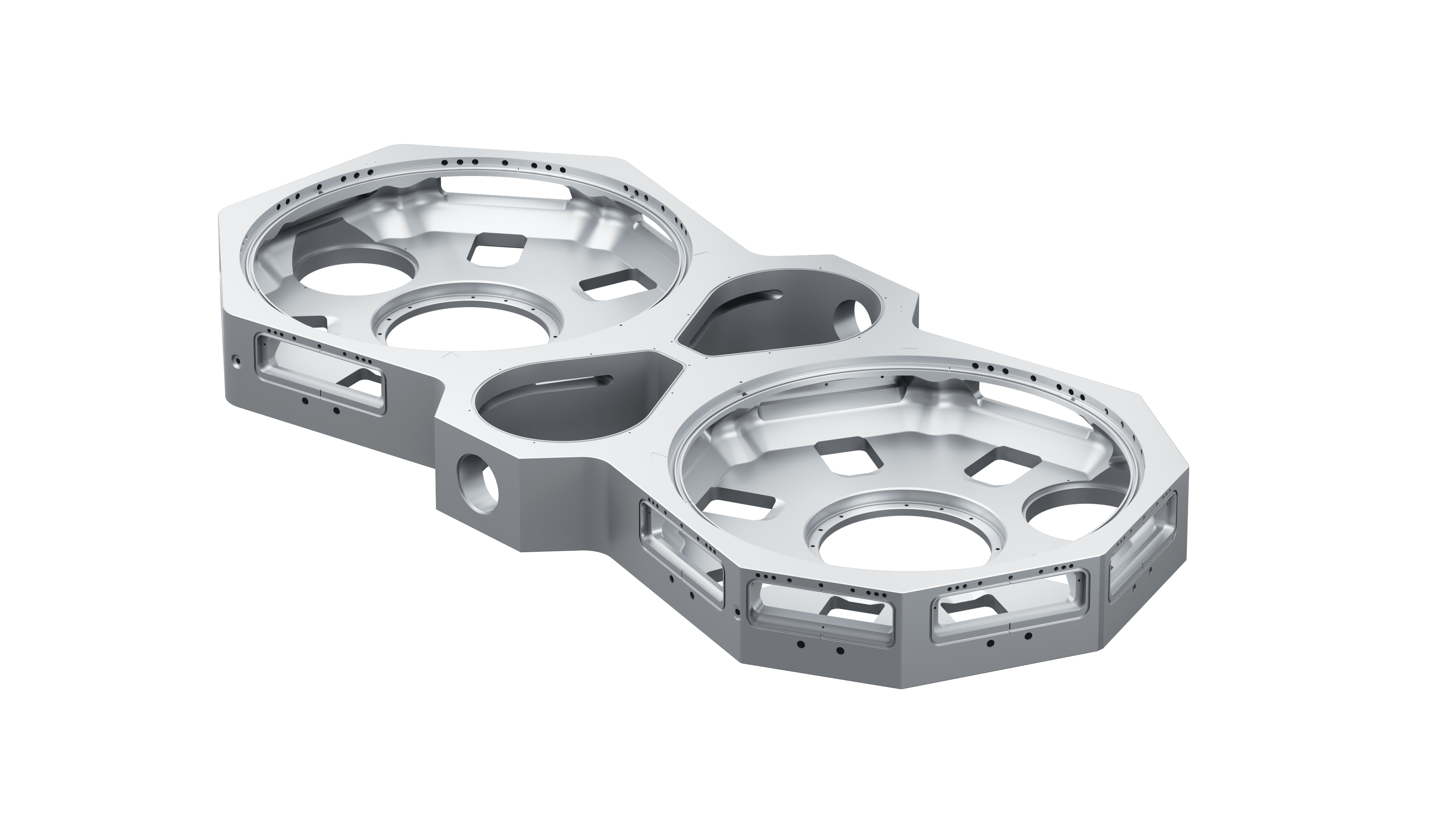

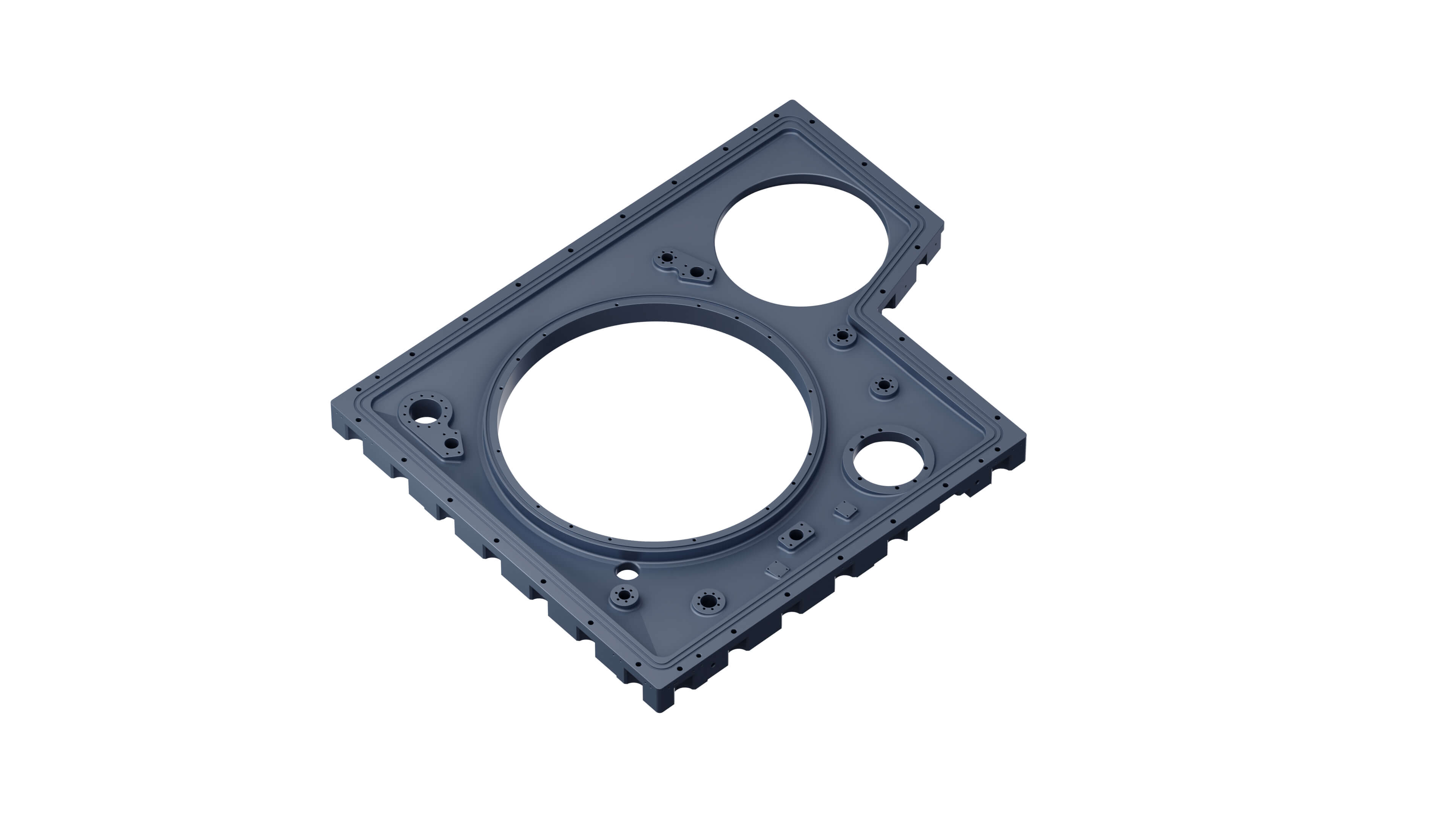

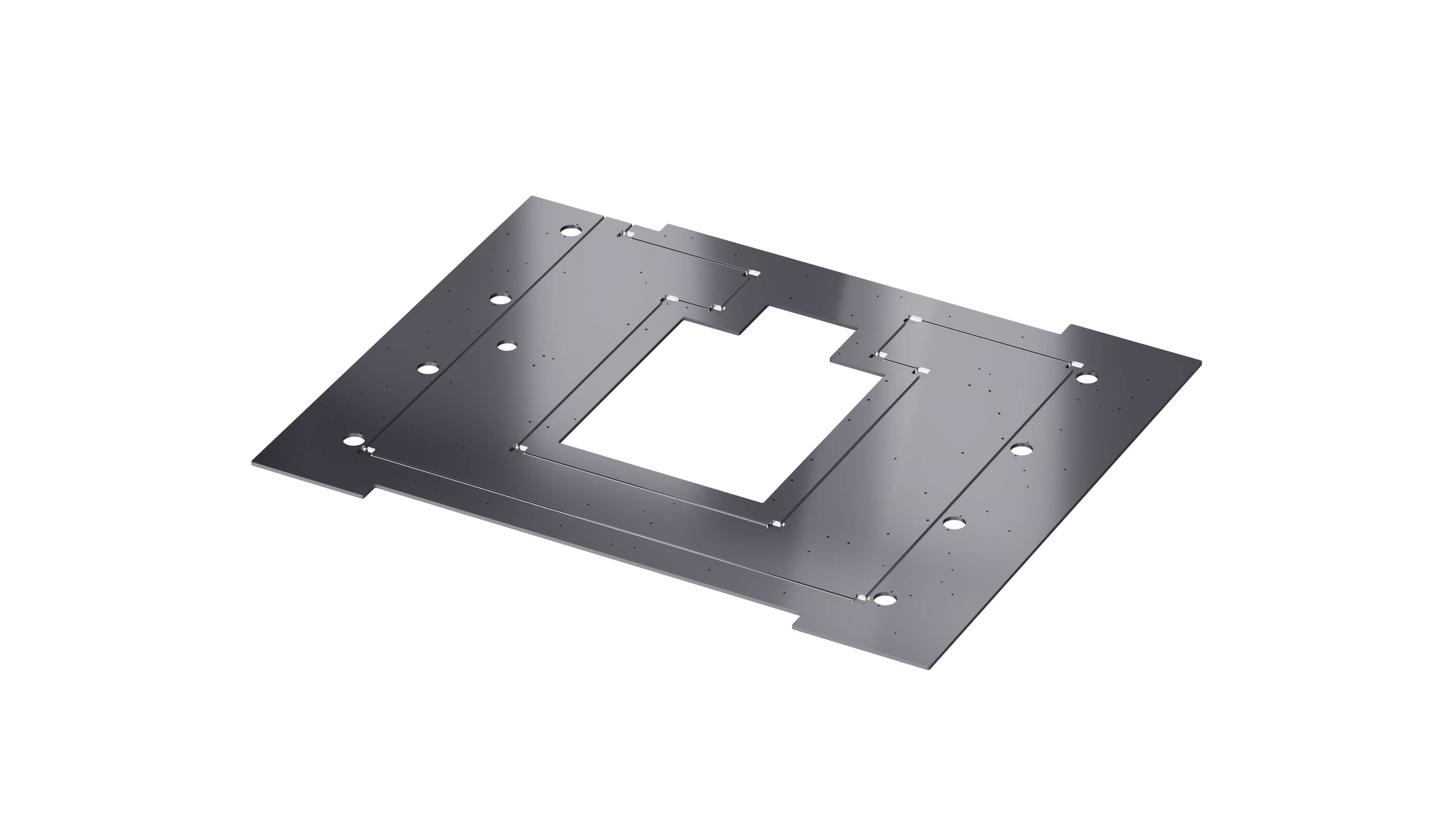

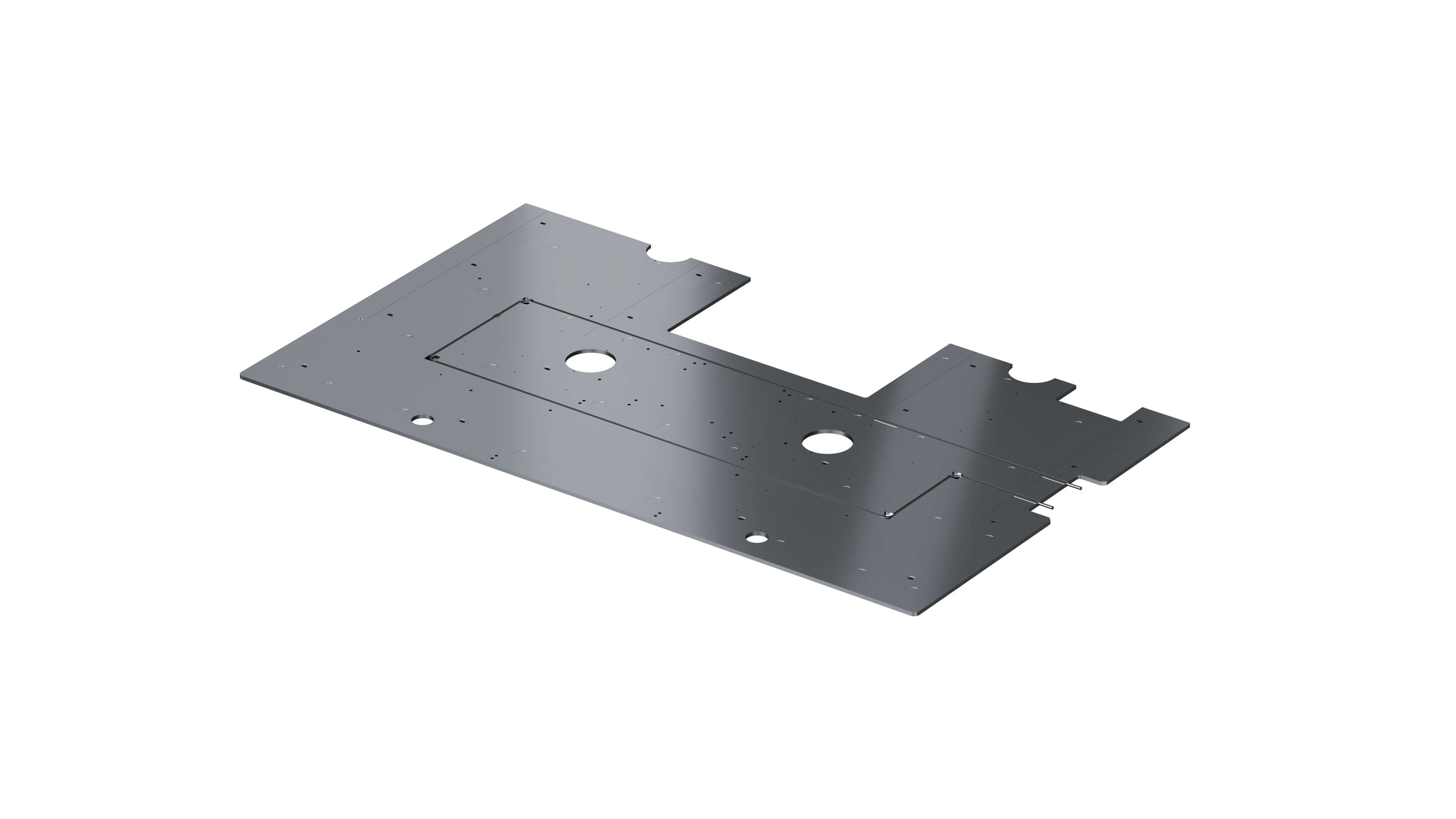

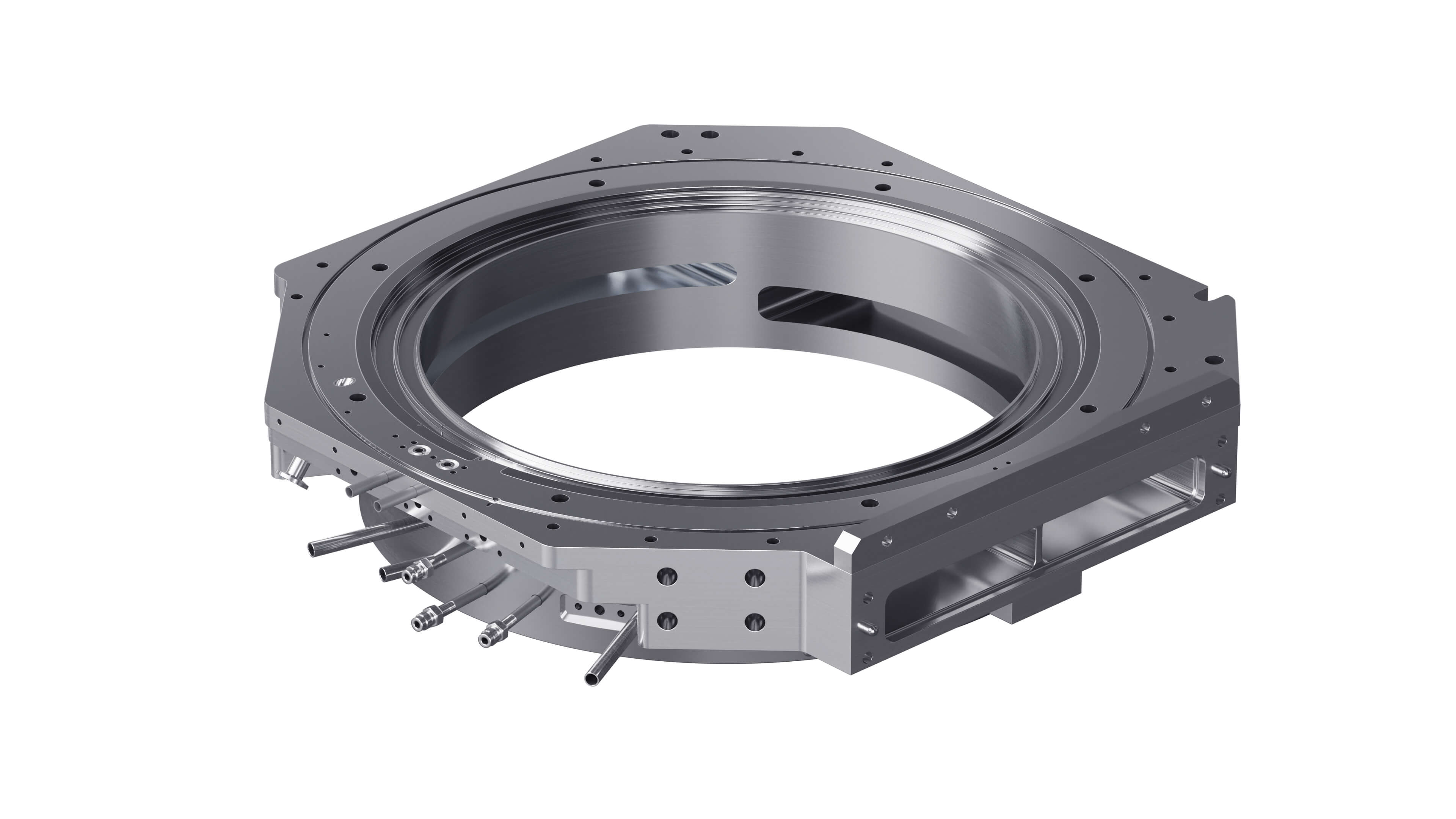

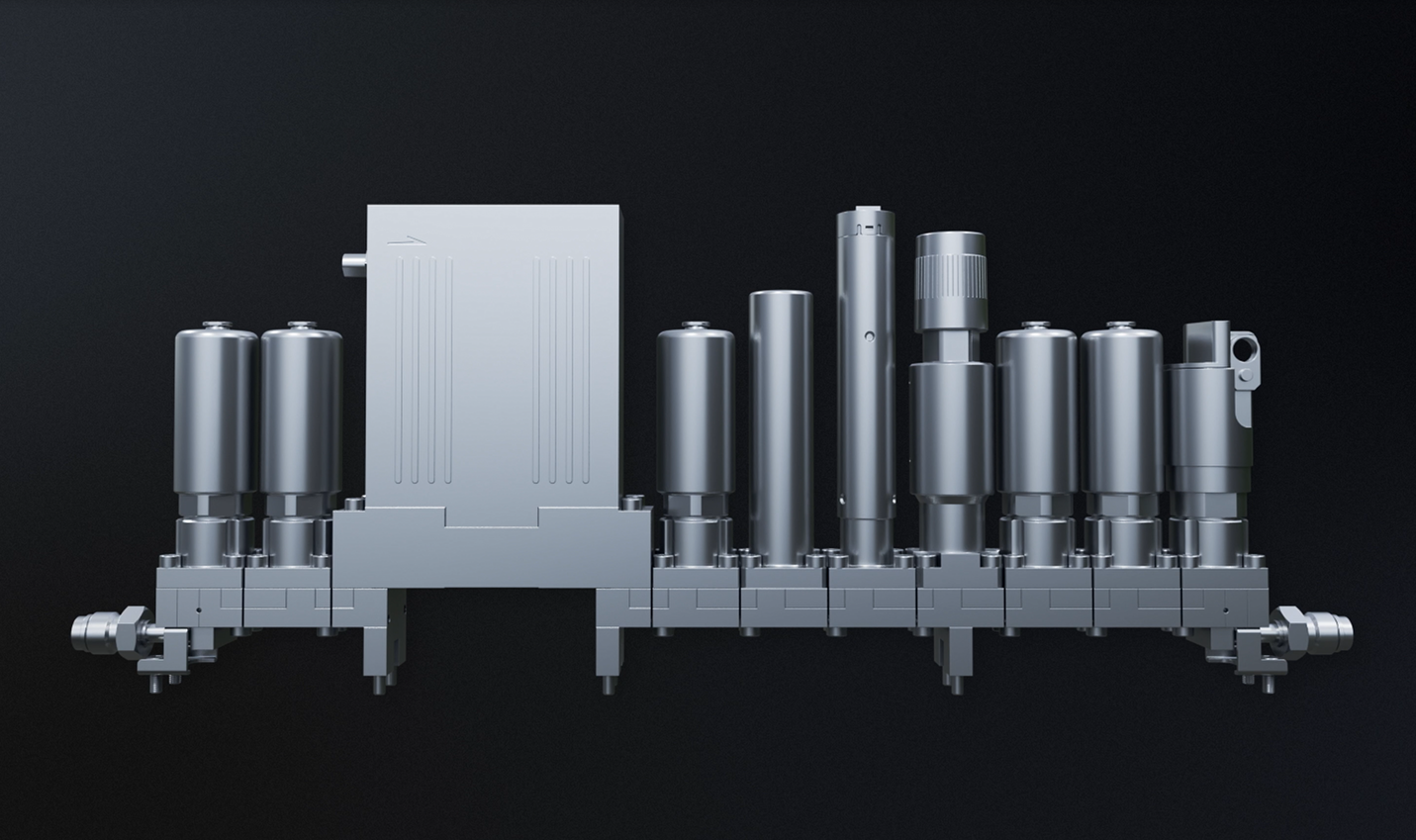

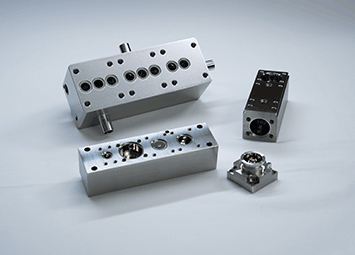

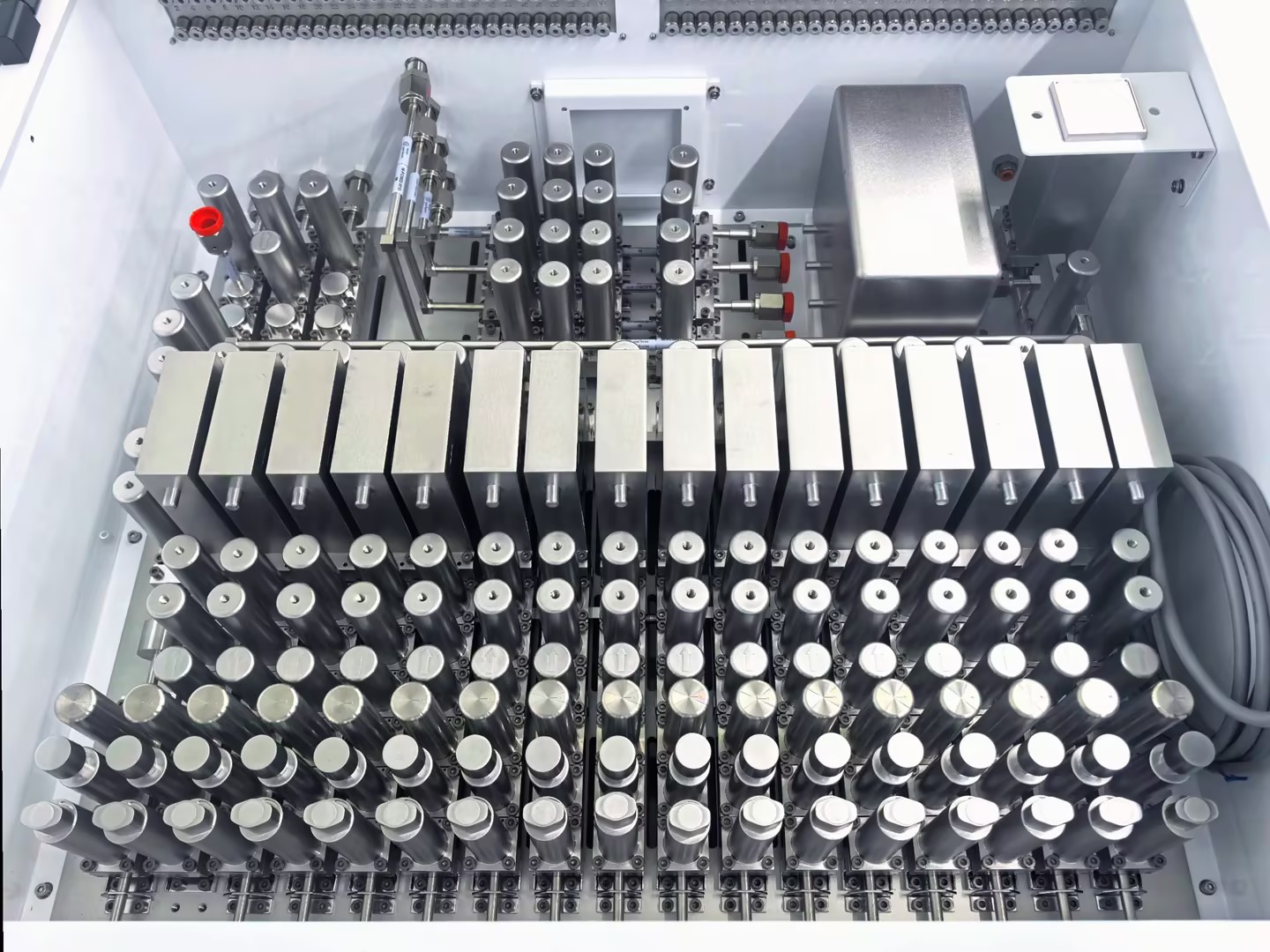

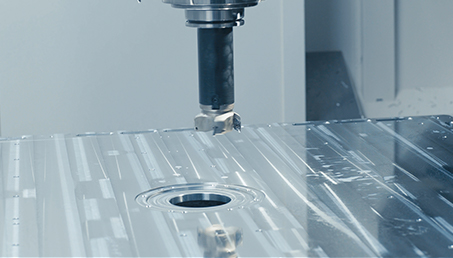

High Precision Multi-Station Complex Profile Manufacturing Technology

Complex surface multi-axis simultaneous machining enables one-stop fabrication of large-size chambers and multi-station features, while also providing integrated solutions such as chamber structure optimization and machining plan development.

Learn more

Learn more