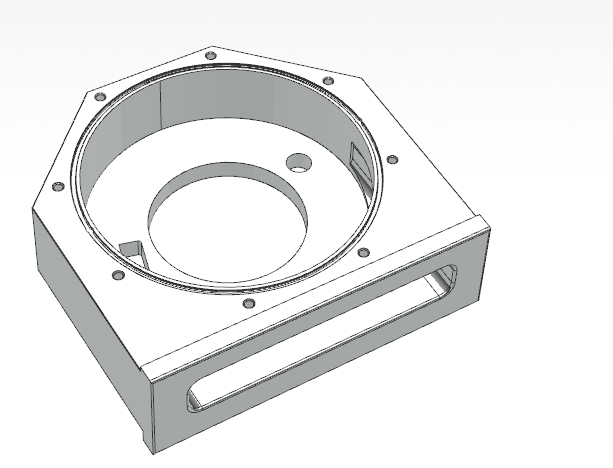

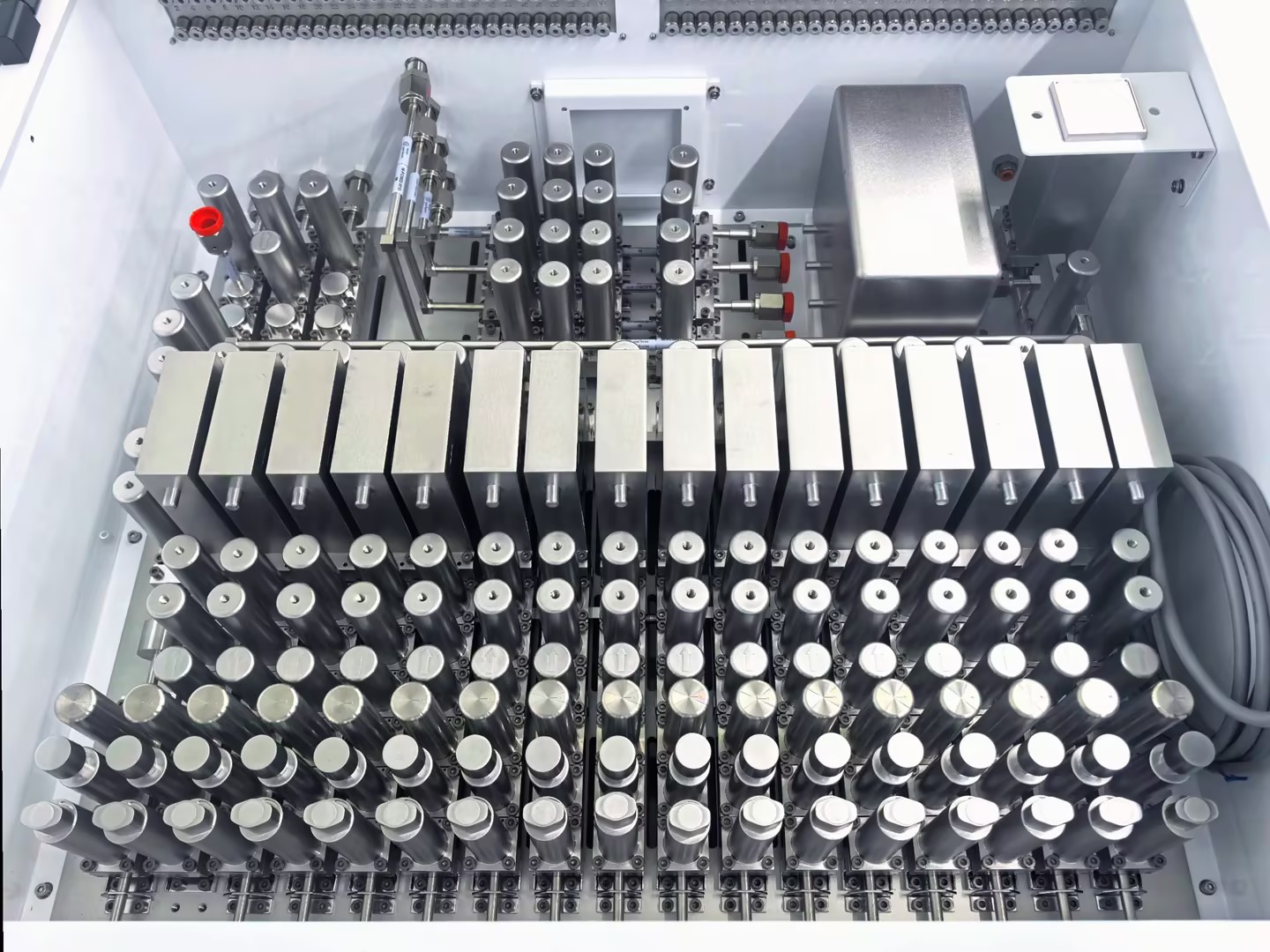

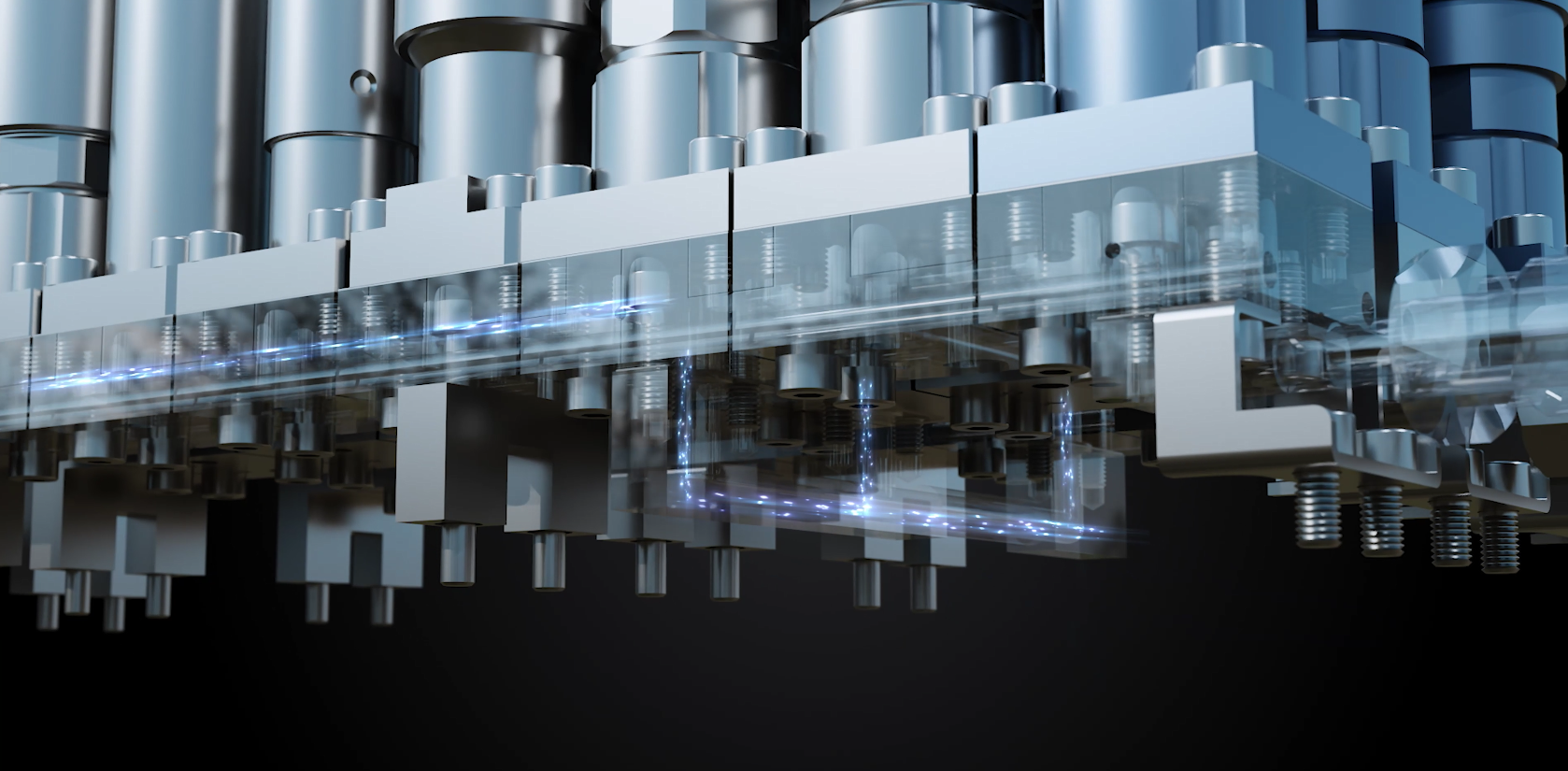

ETCH Process GasCabinet

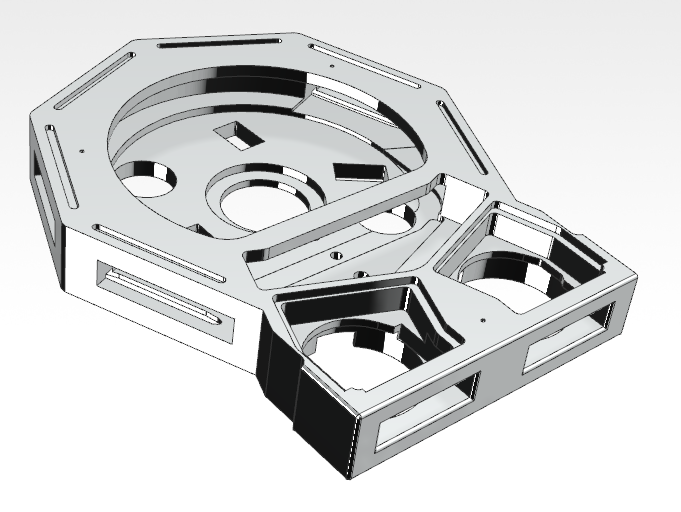

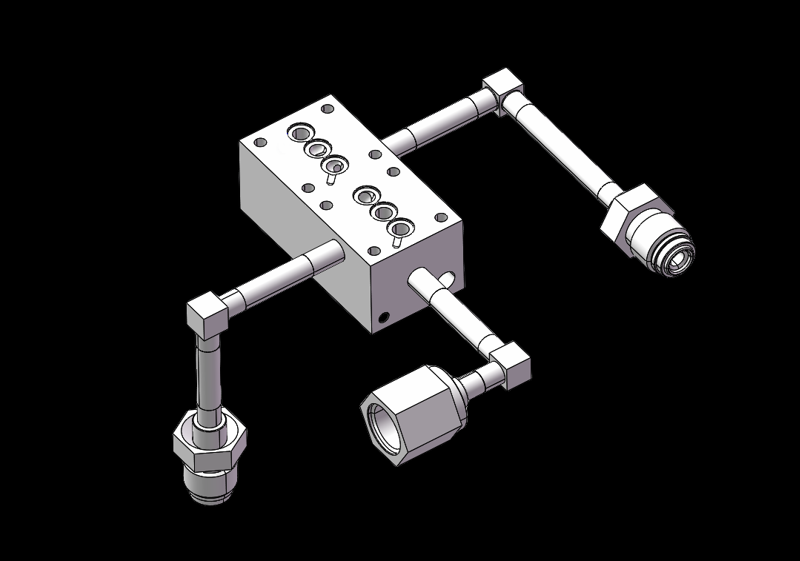

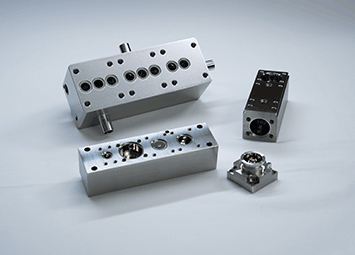

Among the three major processes – thin film deposition, photolithography, and etching – the etching process is of paramount importance, demanding adherence to stringent technical and procedural requirements. The Etch Process Gas Delivery Control Cabinet serves as the core part of gas source control component in etching equipment.

Consult an Expert

Consult an Expert

-

Product Features

-

Product Parameters

Product Features

High precision flow control:

Characterized by a pressure-based Mass Flow Controller (MFC), this design facilitates intricate gas path control and gas mixture formulation.

Optimized gas path design minimizes dead zones. This, in turn, reduces gas flow path length and mitigates the impact of flow fluctuations, improving system stability and control accuracy.

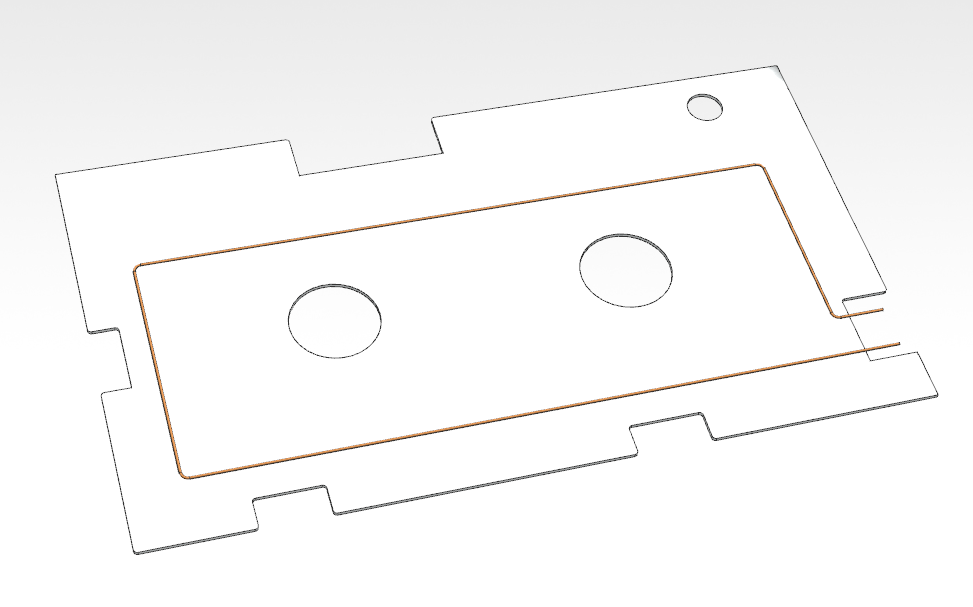

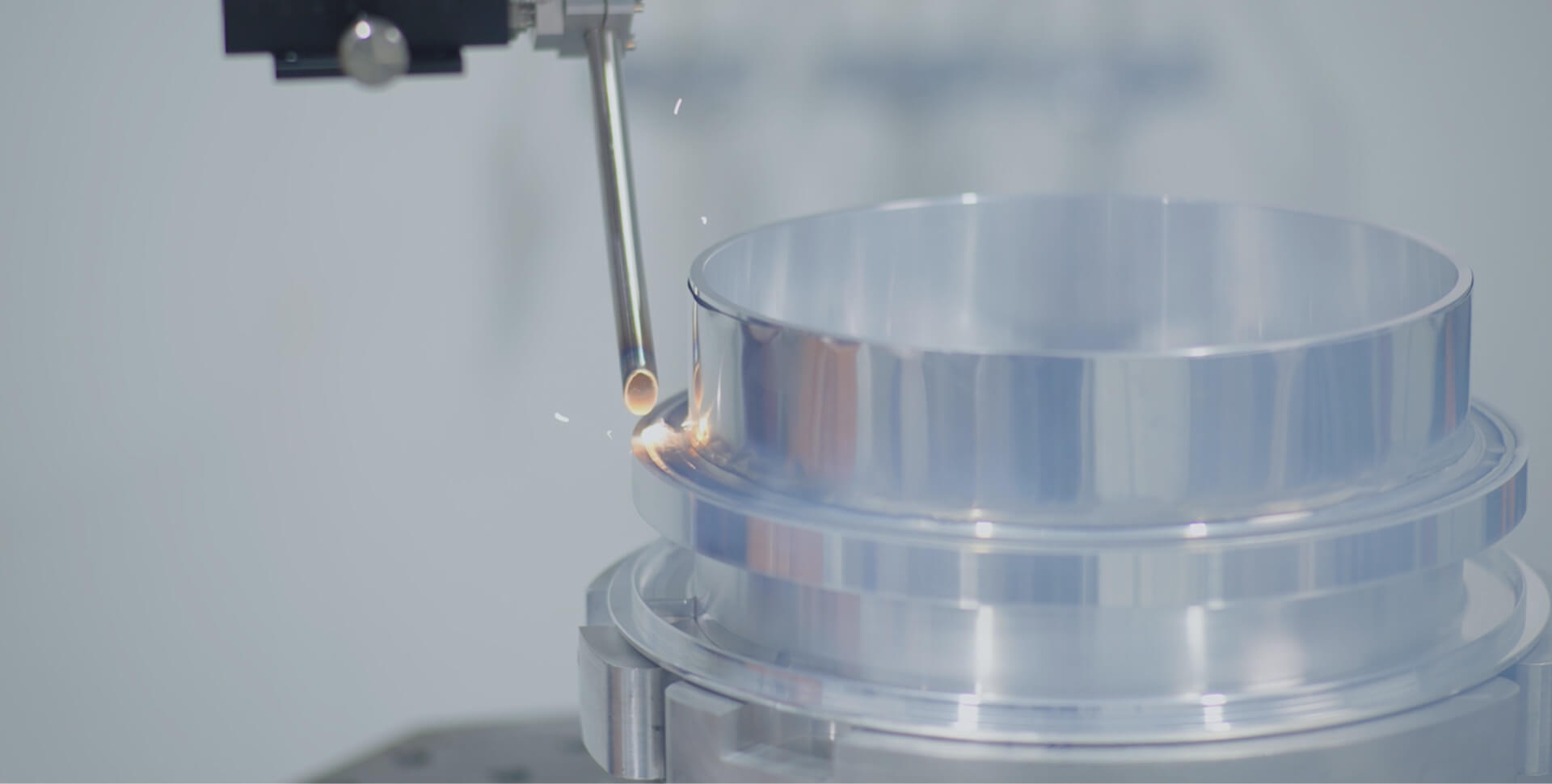

Safety and Stability:

The gas box is equipped with safety components such as door interlock switches, pressure safety switches, and check valves to ensure safety.

The equipment incorporates explosion-proof, corrosion-resistant designs, enhancing safety performance.

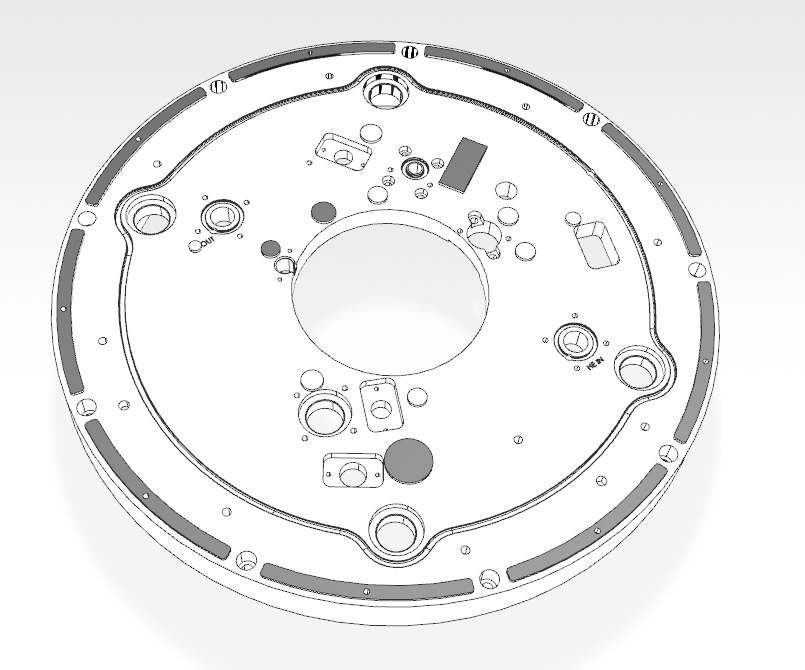

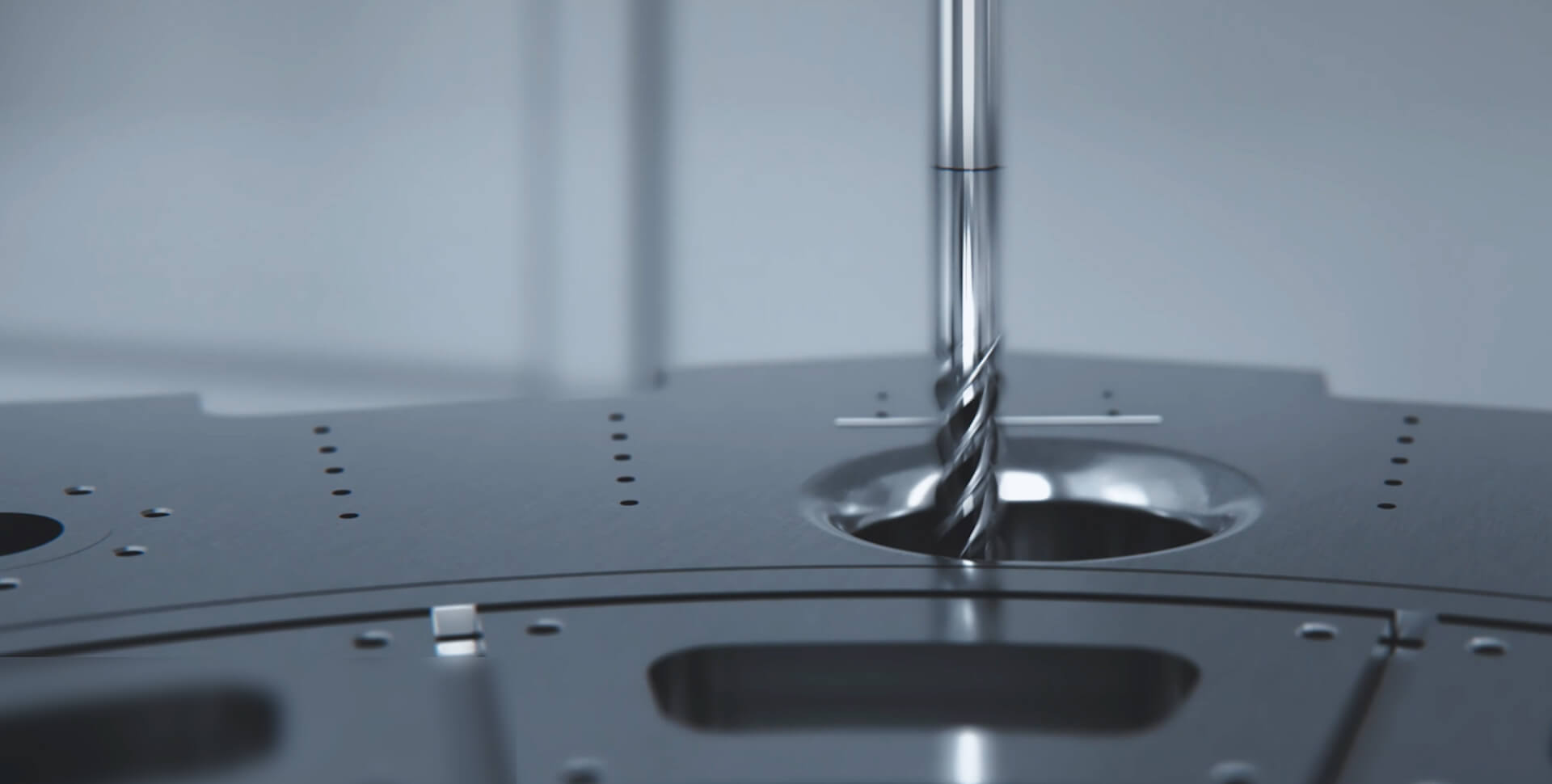

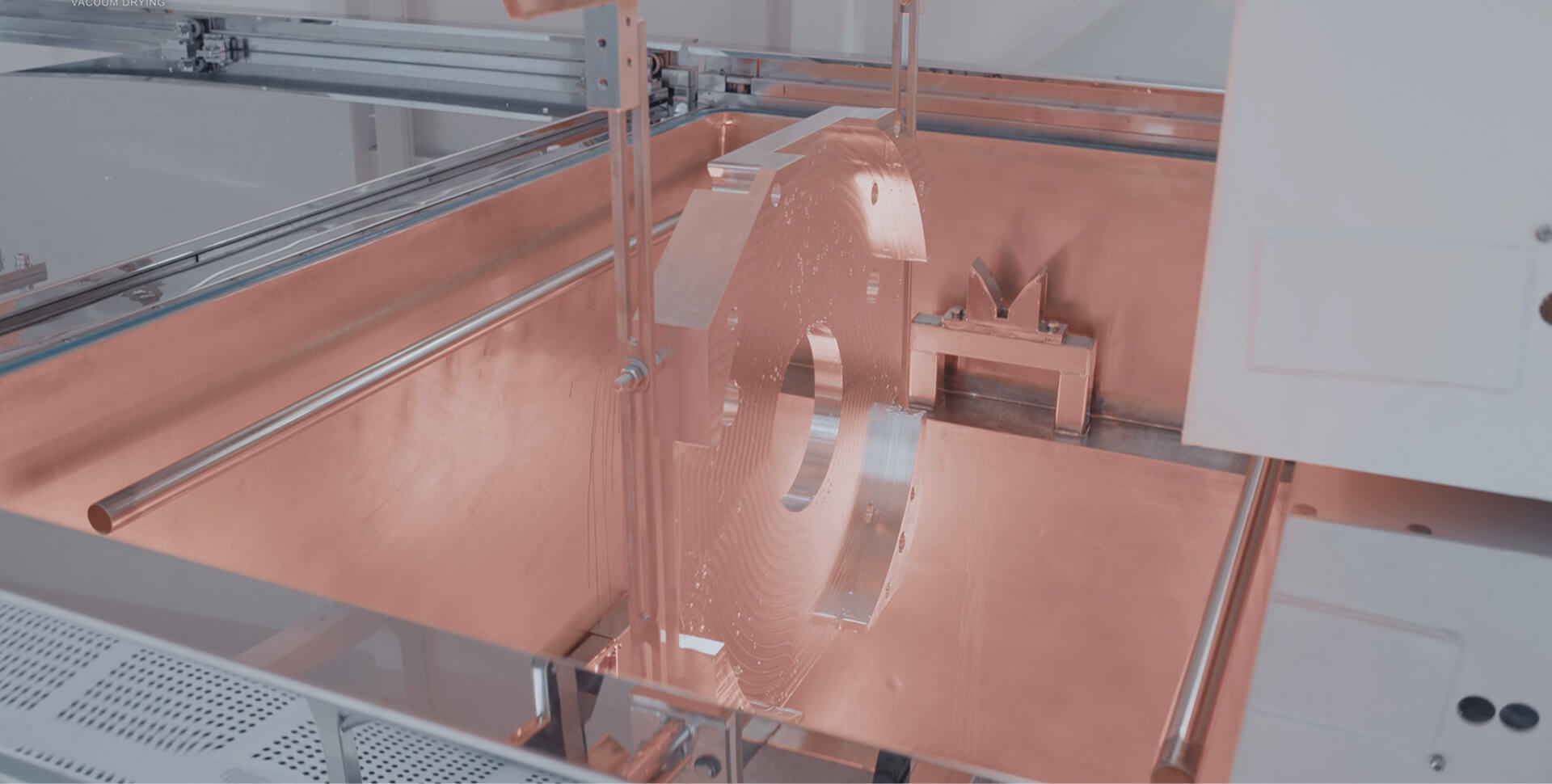

High Airtightness:

The product utilizes IGS and VCR interface types to achieve high airtightness for semiconductor equipment.

High Cleanliness:

Designed for the removal of particle impurities, this system utilizes high precision filters with a retention rating of 3 nm.

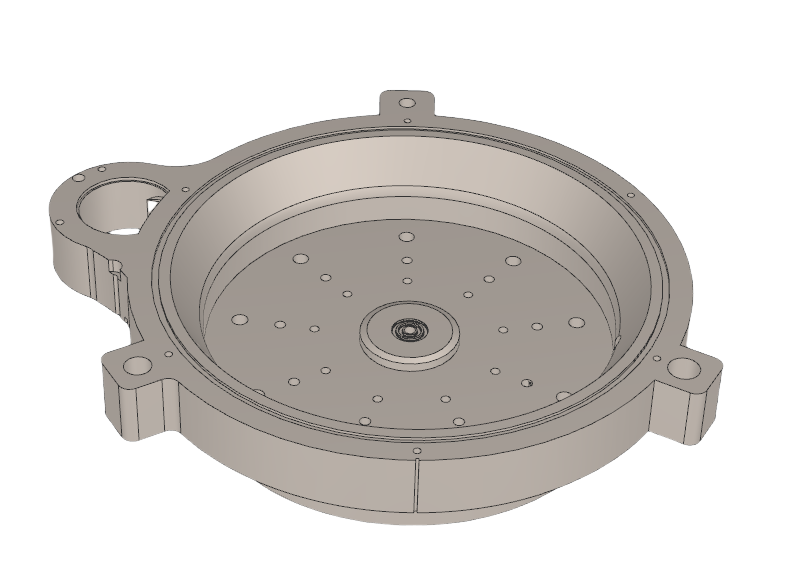

Safety Certification:

Passed SEMI S6 safety certification testing.

Product Parameters

| Outboard leakage rate test: | ≤1.0X10-11/mbar·L/s |

| Inboard leakage rate at seat: | ≤1.0X10-9/mbar·L/s |

| Pressure hold test 50psi: | Nitrogen pressure hold test, hold for 12h, pressure drop ≤1% |

| Helium into a bag leakage rate: | ≤1.0X10-9/mbar·L/s; (Optional) |

| Particle test: | (5 particle @ >0.1um) |

| Moisture and oxygen test: | Moisture content ≤10 PPB, Oxygen content ≤10 PPB; (Optional) |