-

Technical Introduction

-

Technology Features

-

Application Scenarios

-

Core Metrics

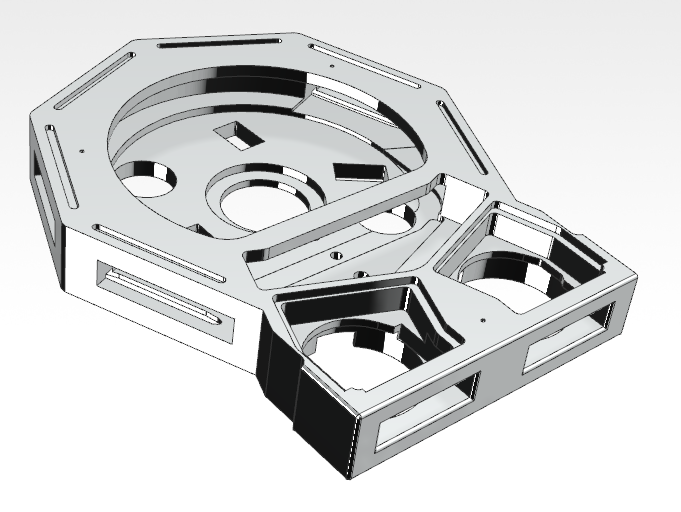

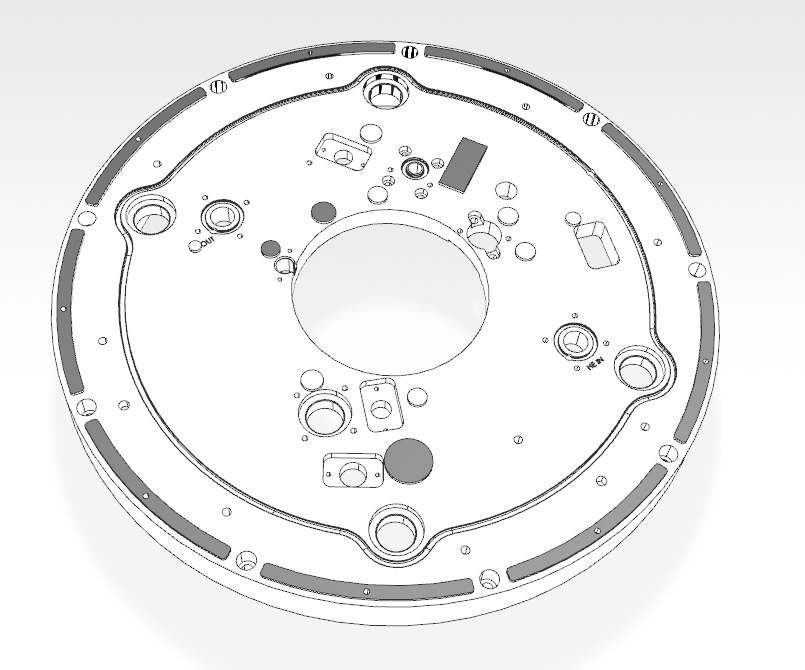

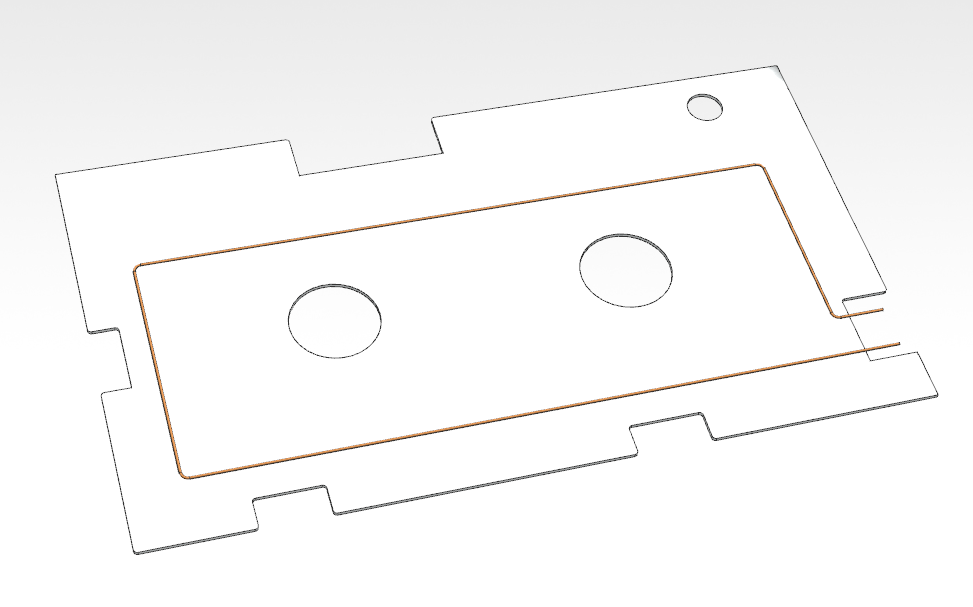

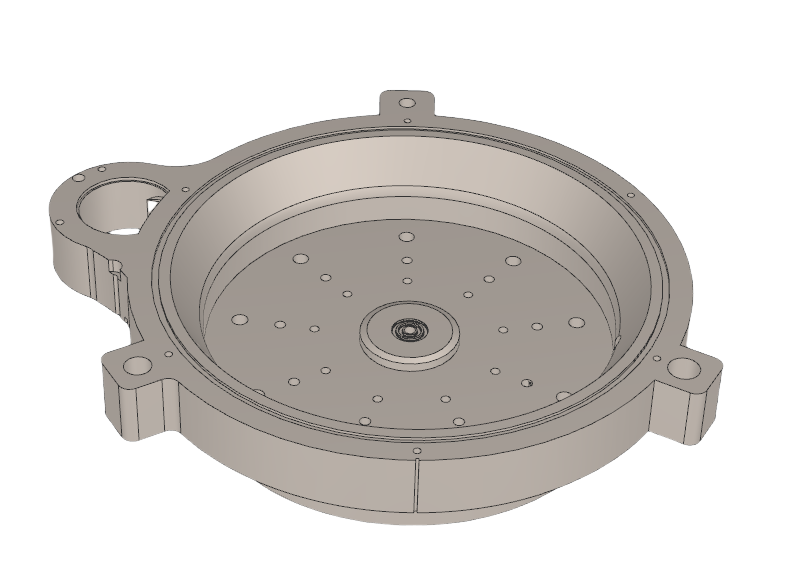

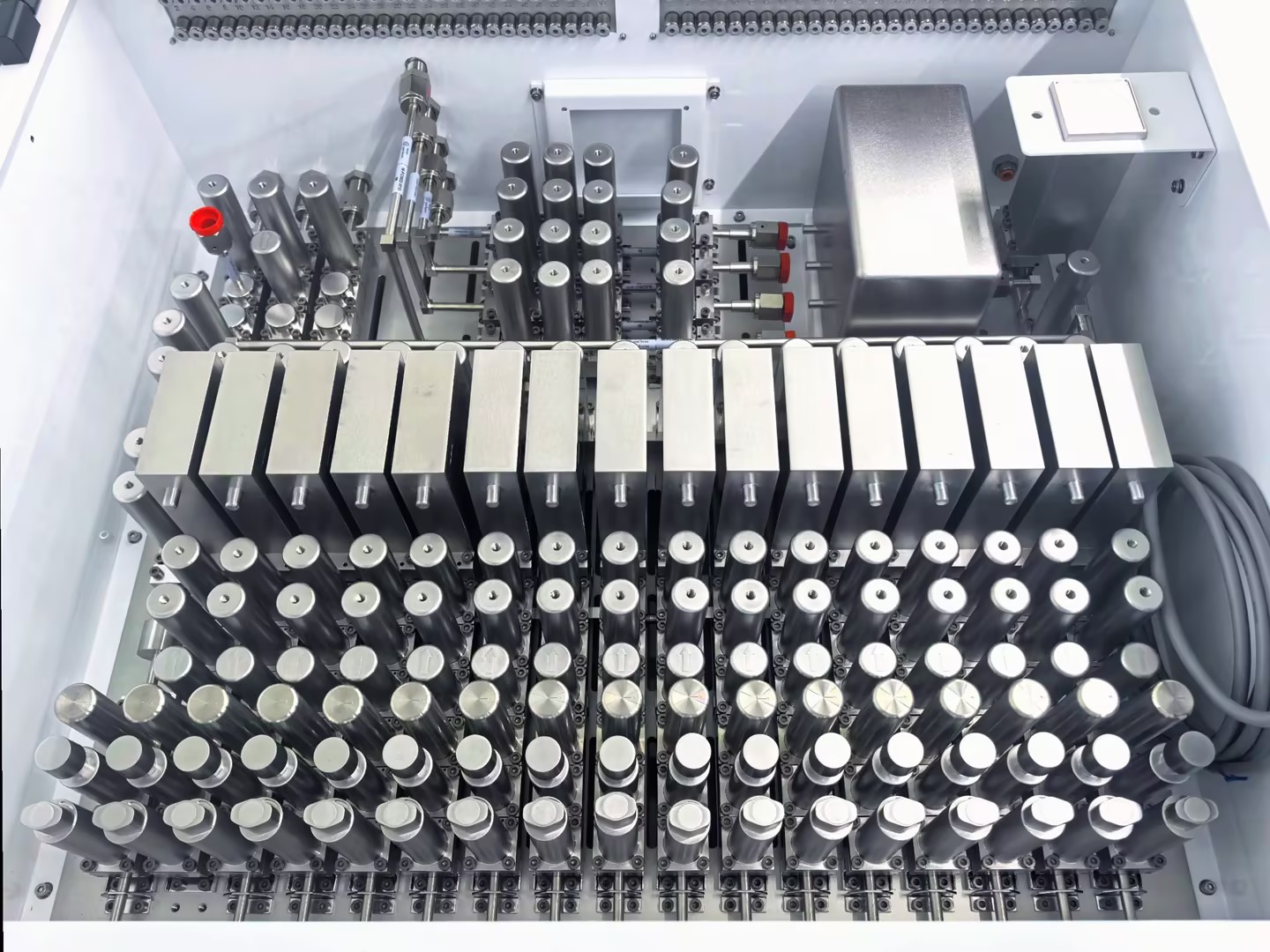

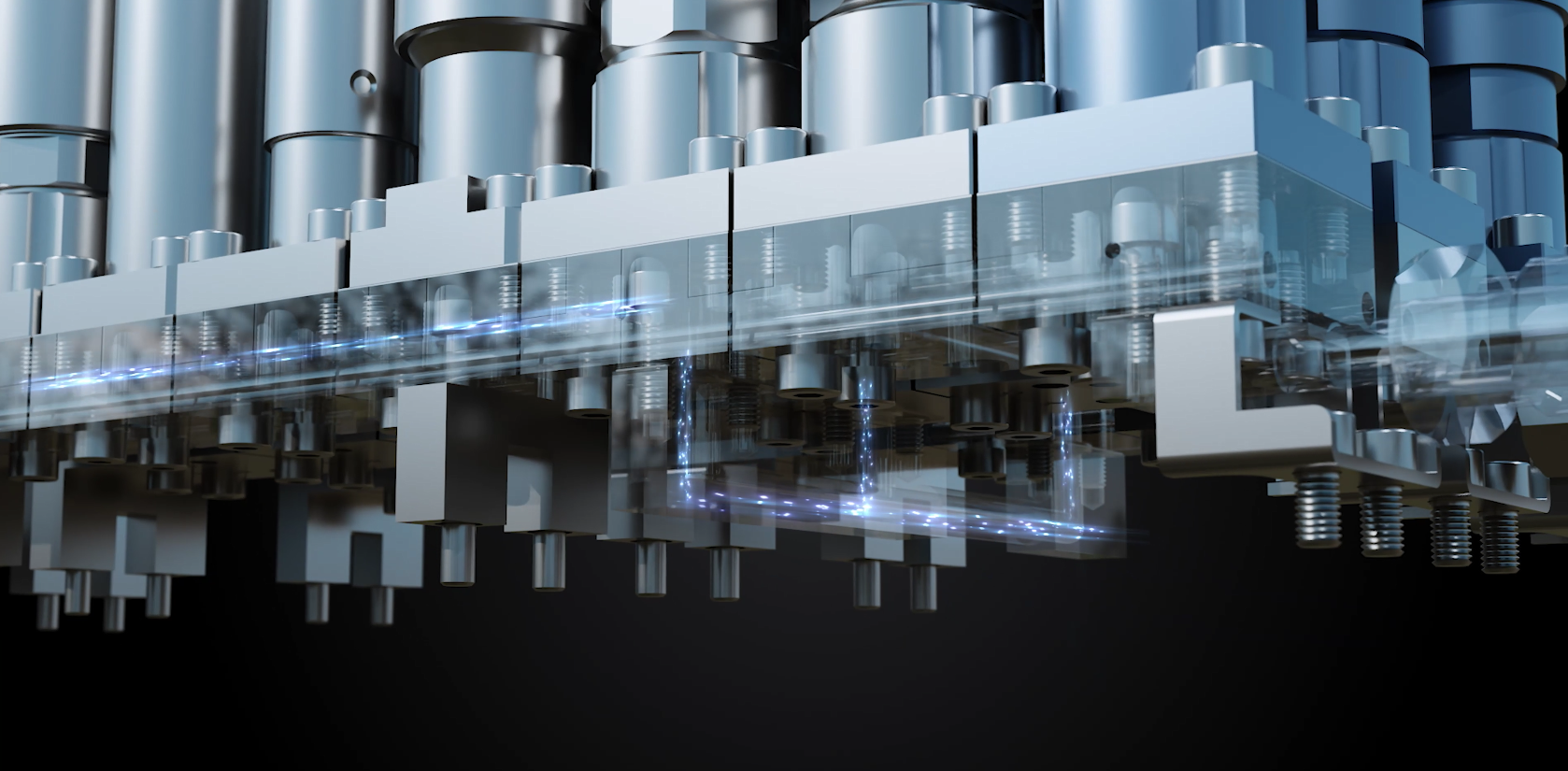

Stainless Steel Ultra-High Surface Finish Stainless Steel Manufacturing Technology

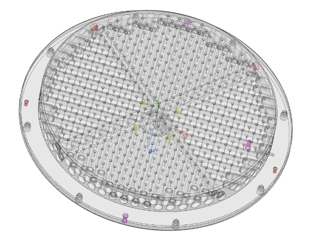

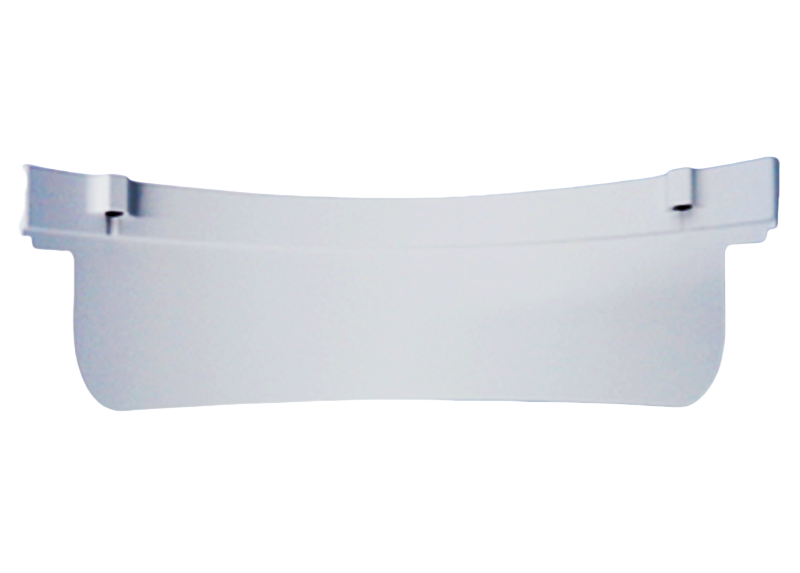

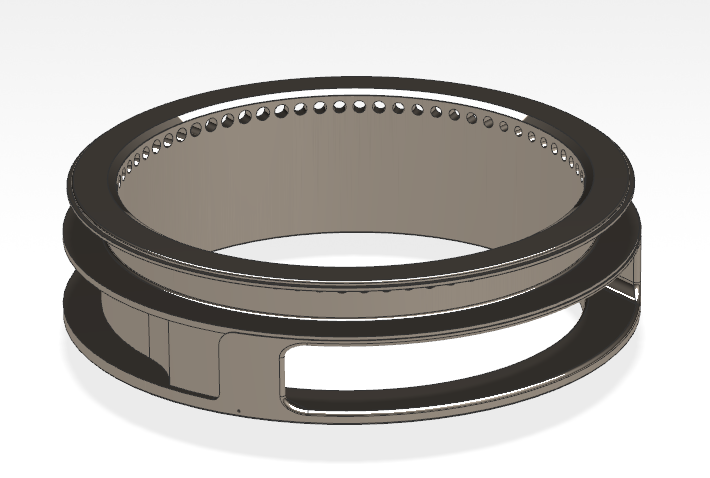

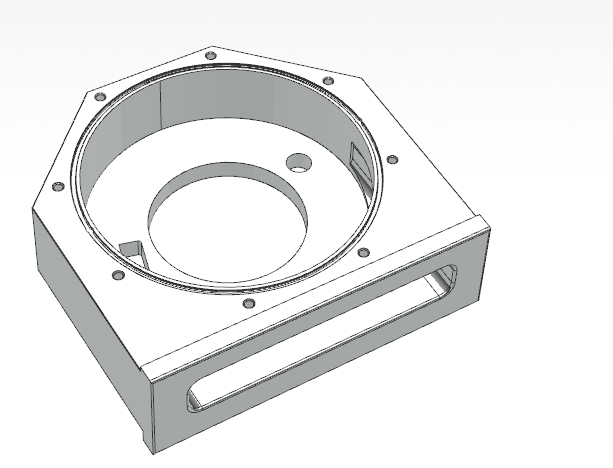

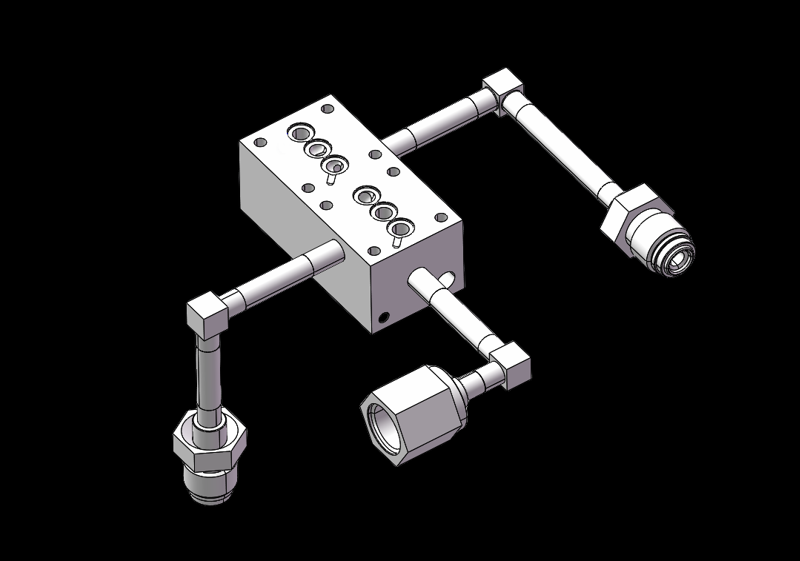

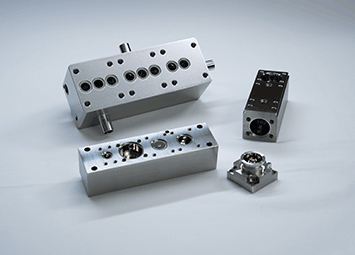

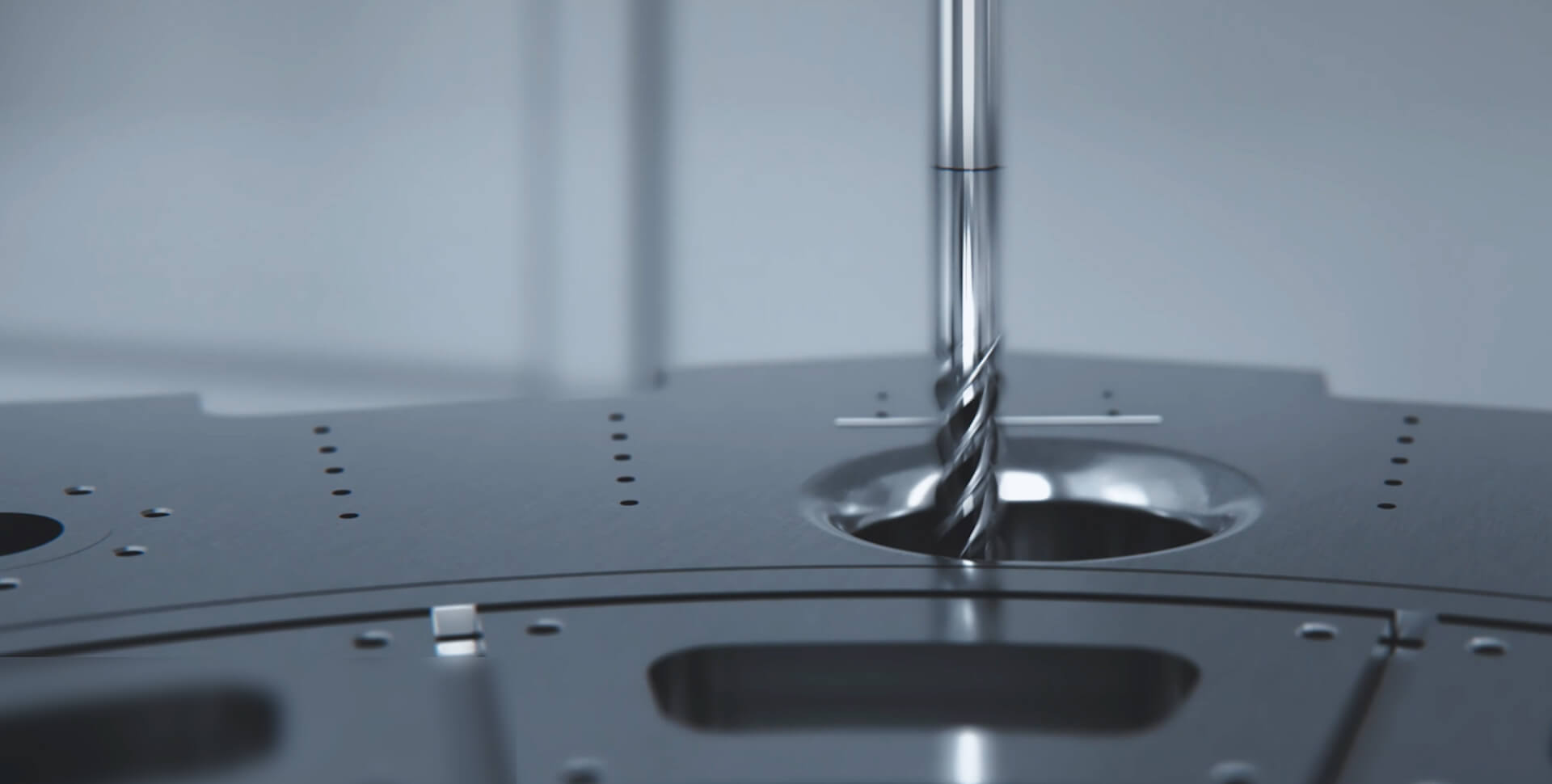

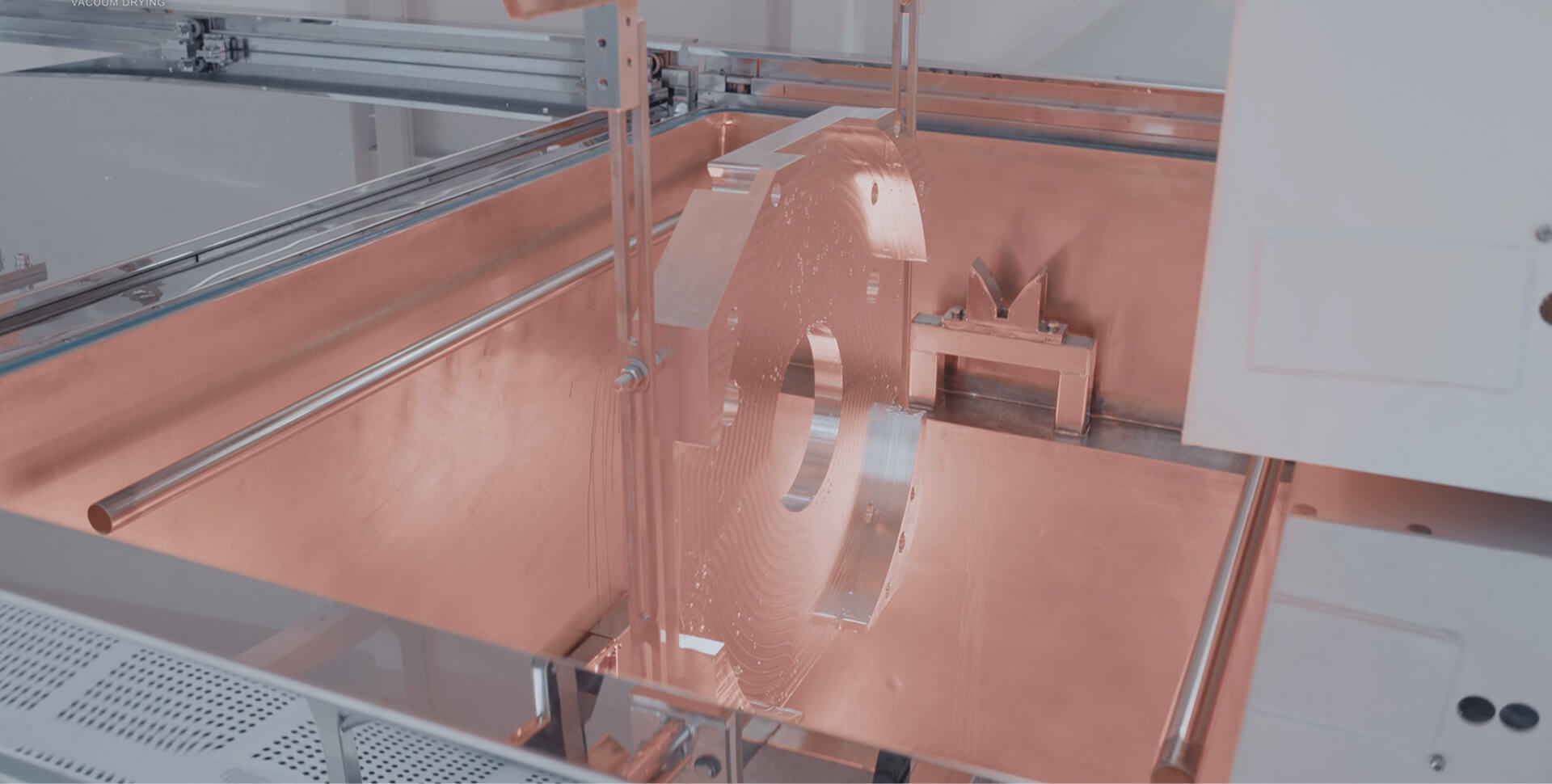

Employing self-designed tooling in conjunction with precision machining technology such as drilling, milling, and reaming, this technology achieves the stringent surface roughness and hardness specifications required for flow channels, functional surfaces, and sealing surfaces.

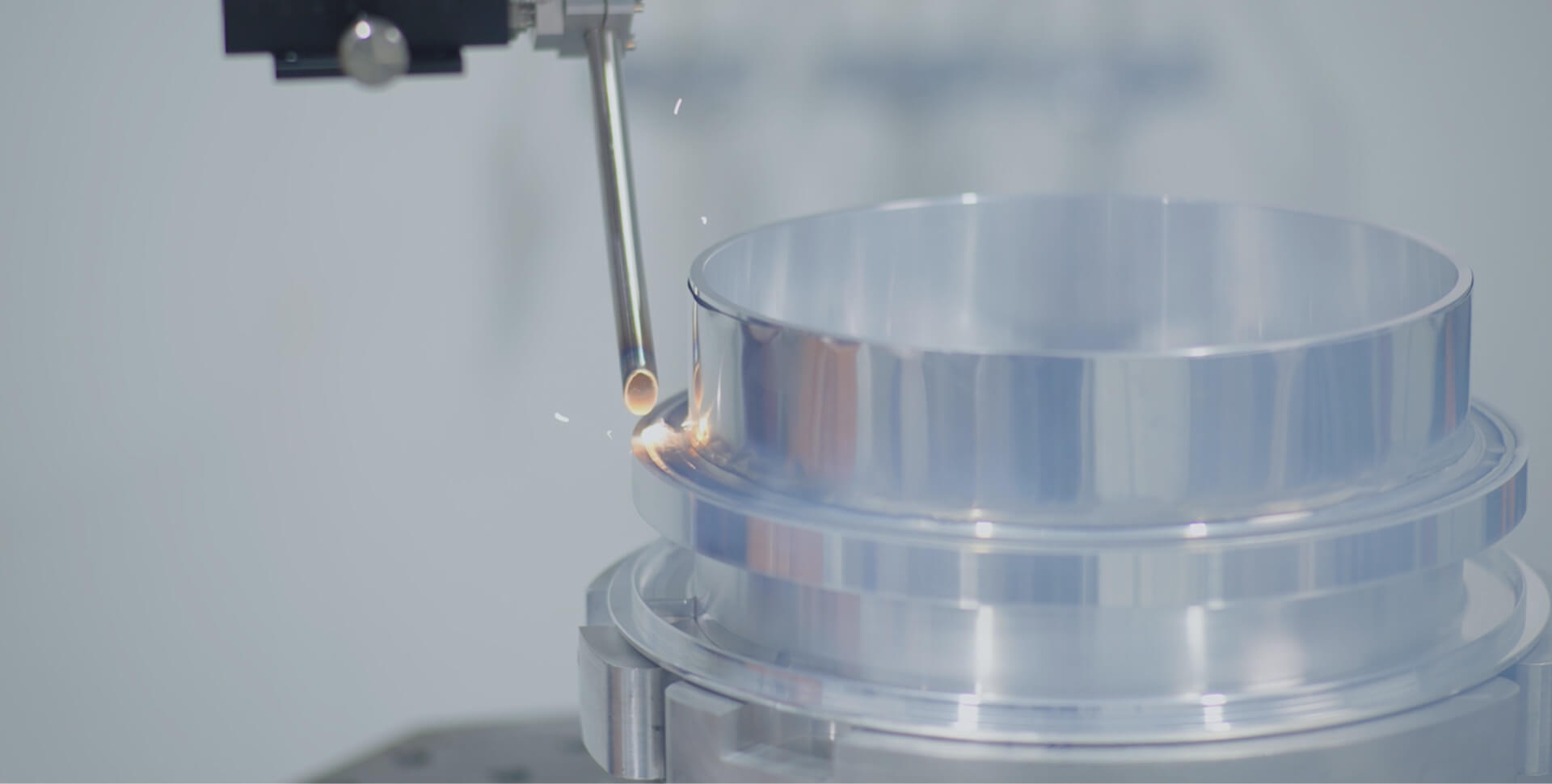

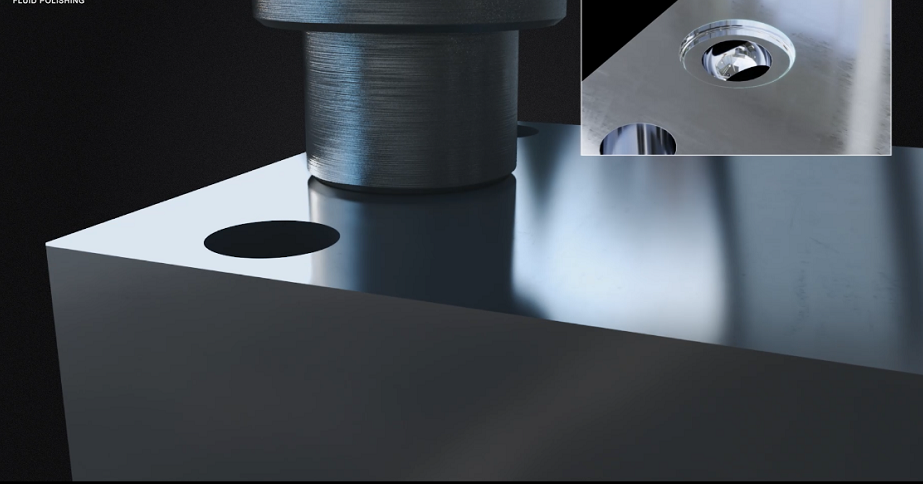

Following machining, stainless steel mirror polishing technology is utilized to improve wetted surface roughness, enabling high-quality, high-efficiency mirror polishing even on complex features.

The product's wetted surface roughness meets SEMI standards and surpasses the stringent requirements of leading international clients, enabling laminar gas flow with minimal turbulence to achieve rapid gas delivery response and corrosion resistance.

Consult an Expert

Consult an Expert

Technology Features

Surface Roughness

Flow Channel Ra < 0.1μm ;Seal Surface Ra < 0.1

01

Flatness

<0.02mm

02

Seal Surface Hardness

>300HV

03

Application Scenarios