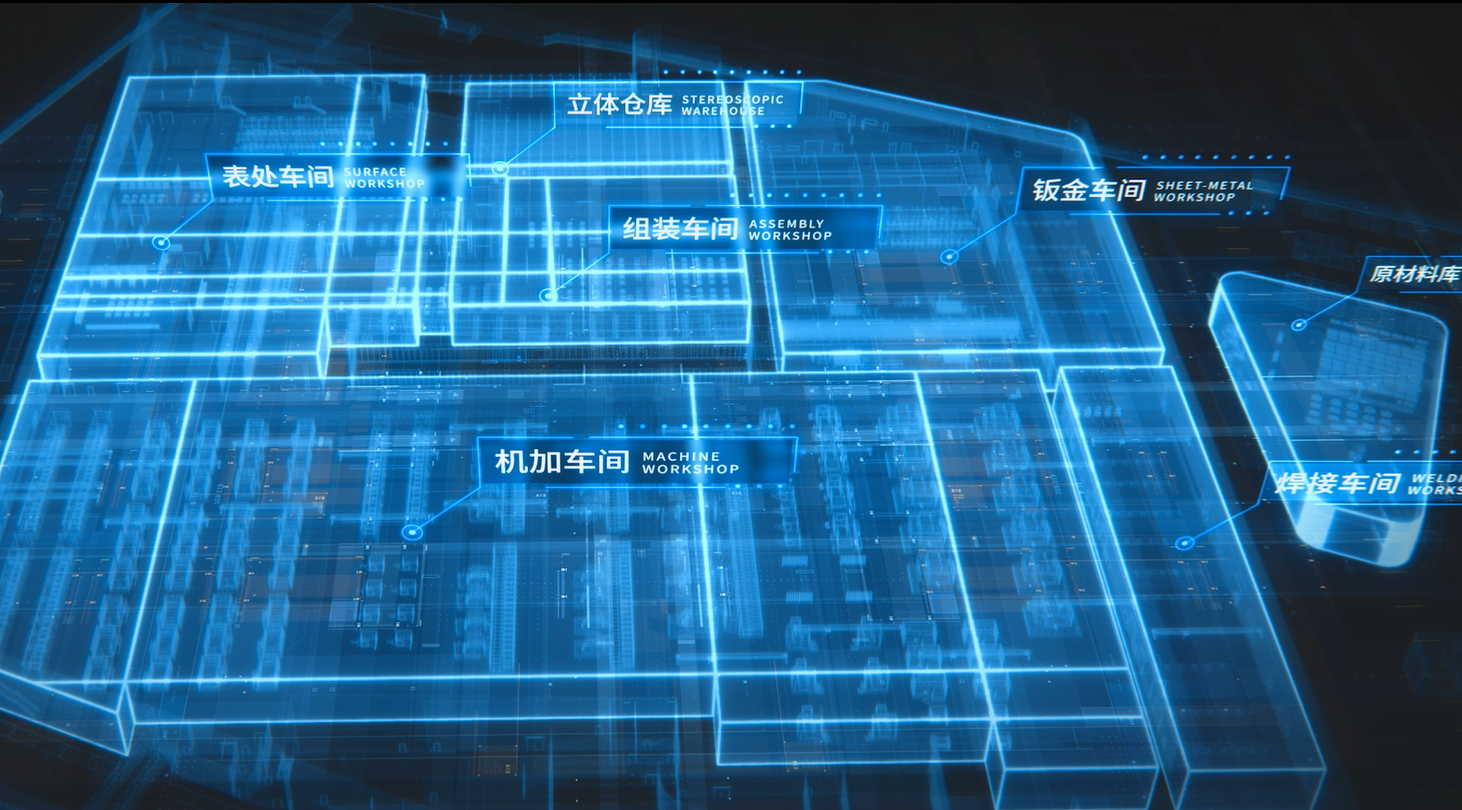

Digital Intelligence Factory

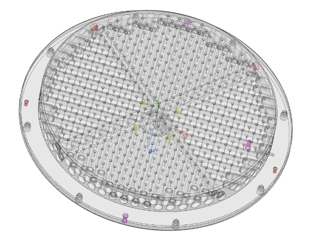

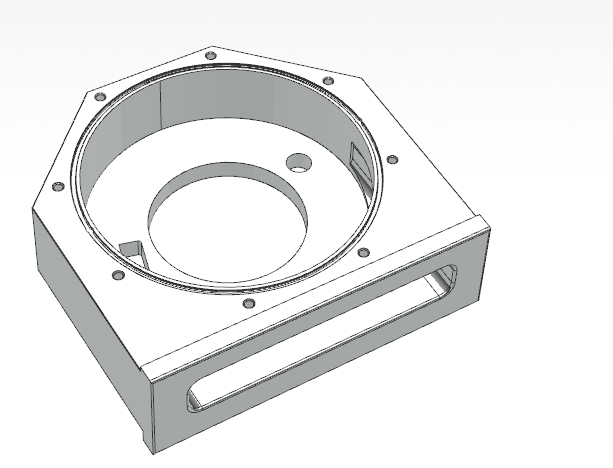

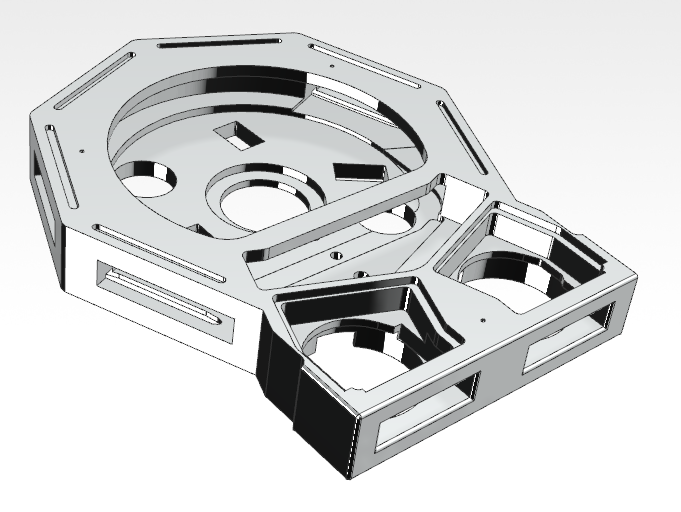

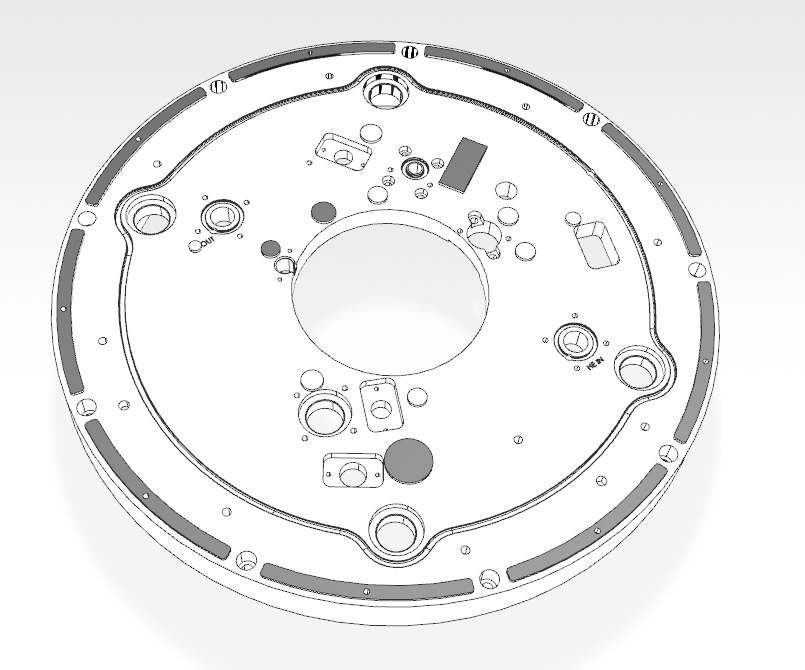

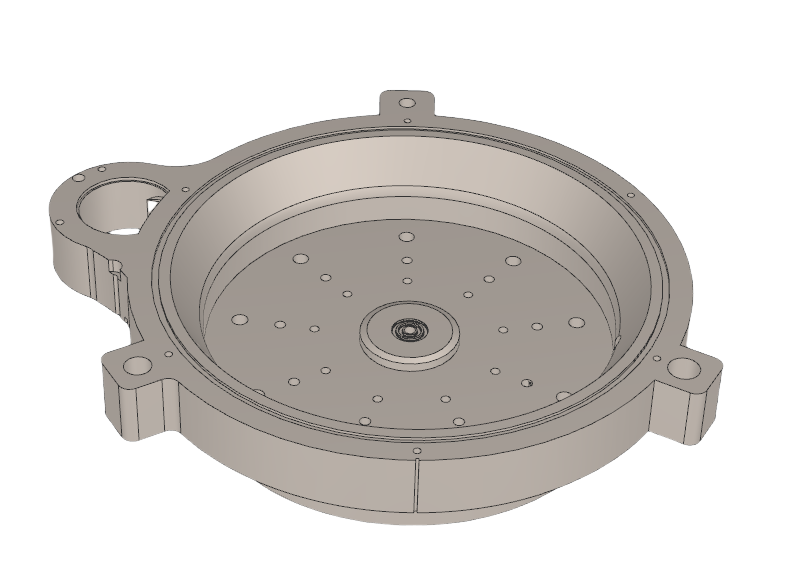

Fortune Precision utilizes core digital technologies like big data, cloud computing, IoT, and AI to build a digital platform centered around an intelligent process expert system, achieving an intelligent manufacturing management model for multi-variety, small-batch, customized discrete products.

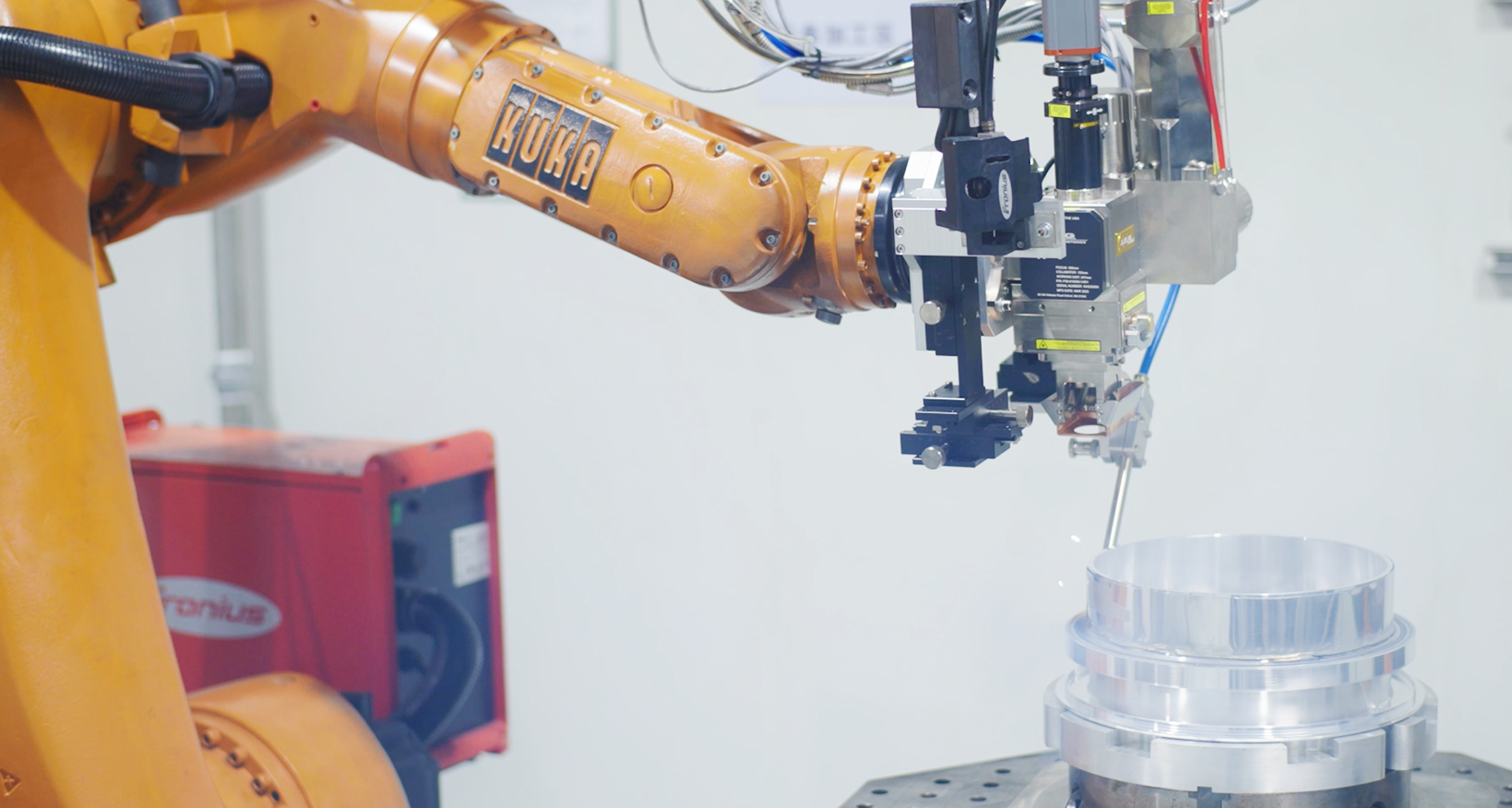

Intelligence and Automation

Step-01

One-Click Process

Conduct secondary development of industrial software, organize industrial technical knowledge, establish a knowledge base, and realize intelligent process design for IC equipment components. On one hand, the one-click process improves process efficiency and facilitates the inheritance of industrial technical knowledge; on the other hand, it outputs large amounts of structured data, providing strong data support for digital workshop construction.

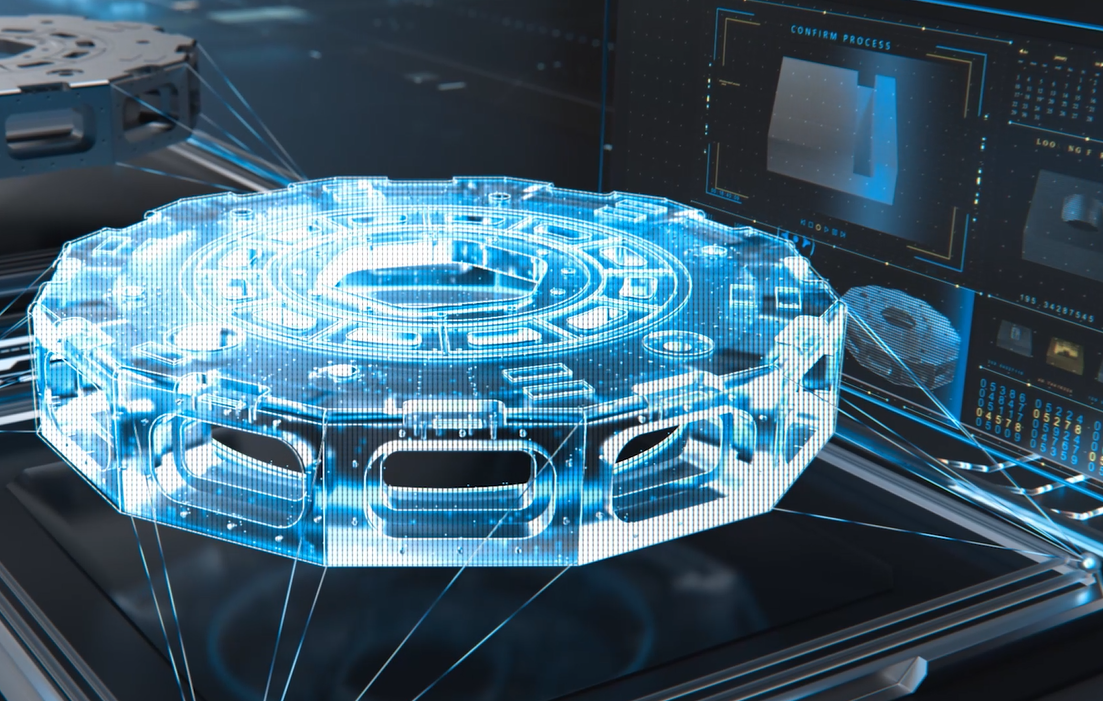

Step-02

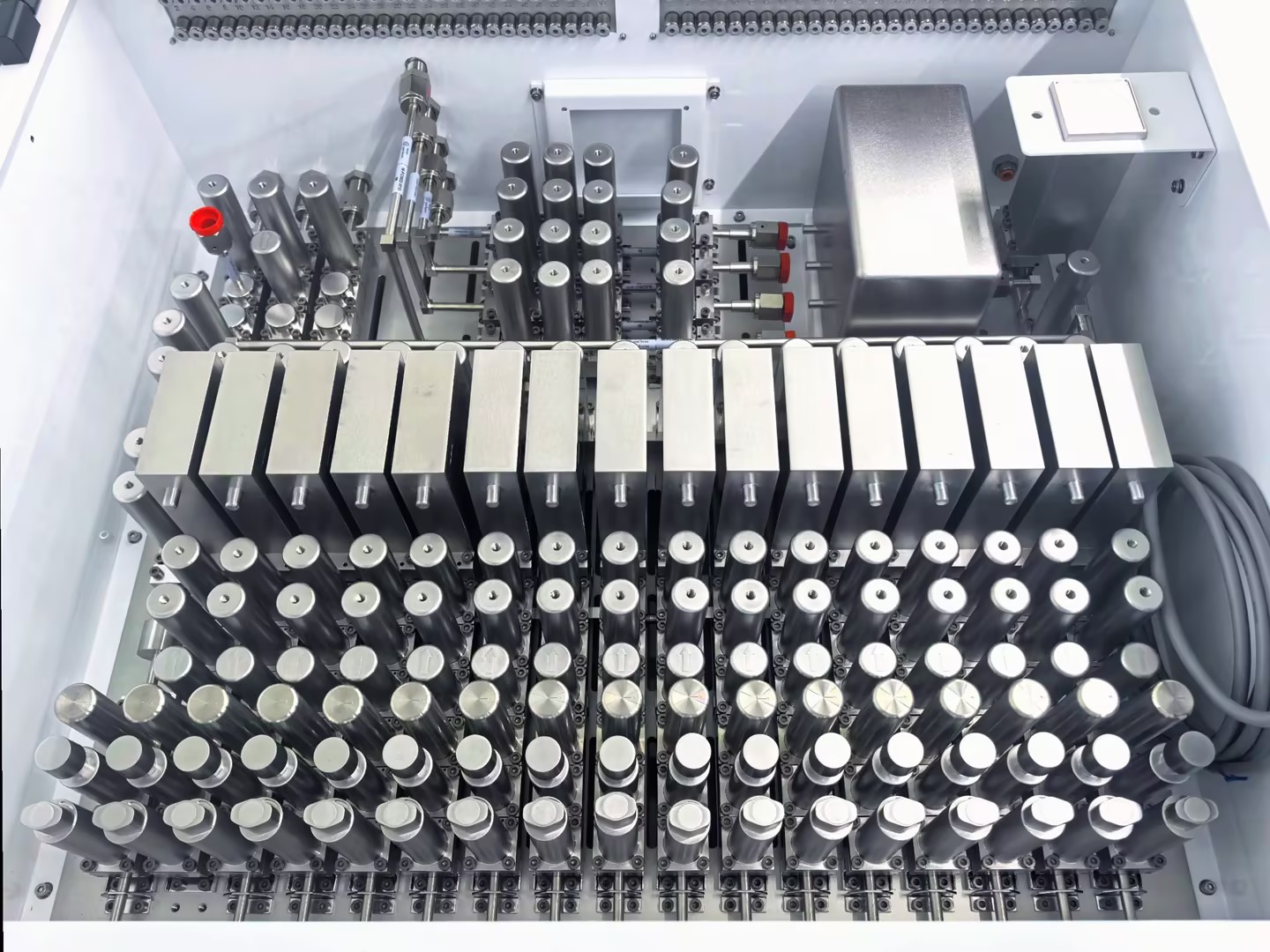

One-Click Manufacturing

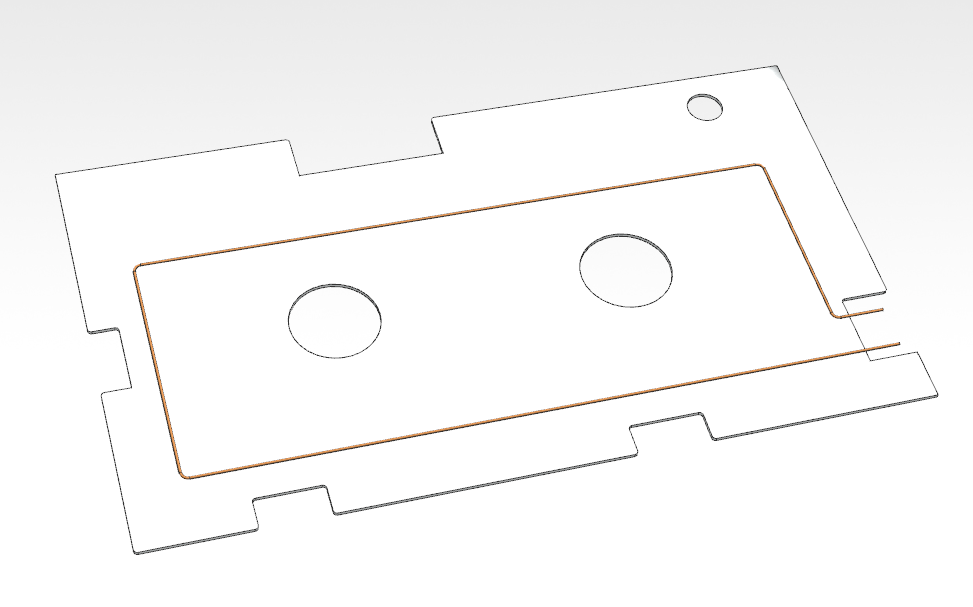

One-click manufacturing is the implementation of the one-click process on the manufacturing side; it is the integration of virtual and real, a digital twin. Based on the large amount of structured data from the one-click process, achieve different production scheduling modes in the workshop, and use custom APPs for task reception and dispatch for turnover positions.

Step-03

One-Click Quality Inspection

In the test program development stage, programs can be automatically generated, reducing reliance on manual operations and personnel skills, achieving leaner operations at the operator level, enhancing the utilization rate of testing equipment, and integrating virtual and real aspects of test program development and execution.

Step-04

One-Click Management

By collecting and monitoring business data to trigger event calls to the knowledge base, the system achieves automatic decision-making, drives indicator judgment and process determination, realizing employee self-drive, leaner management, and business automation.

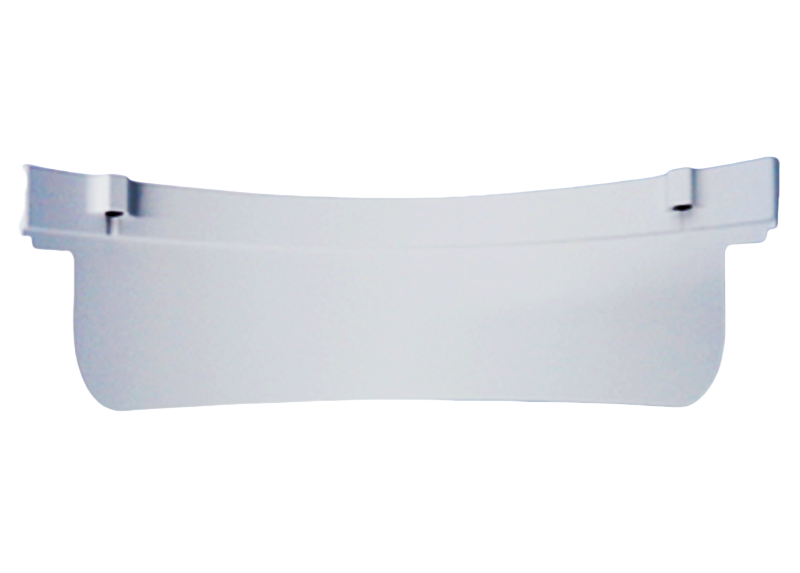

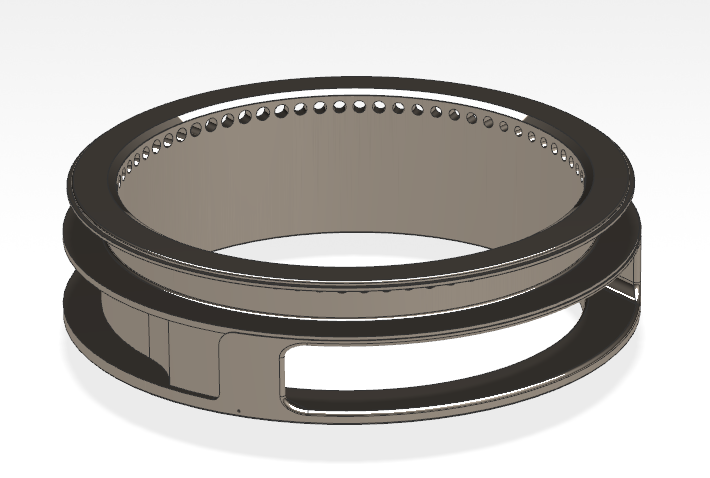

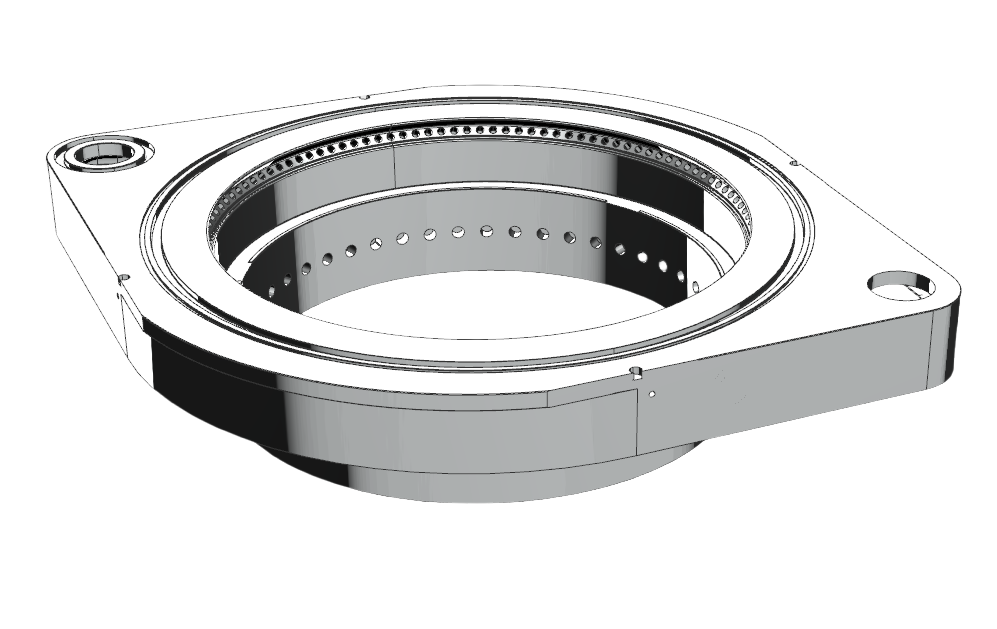

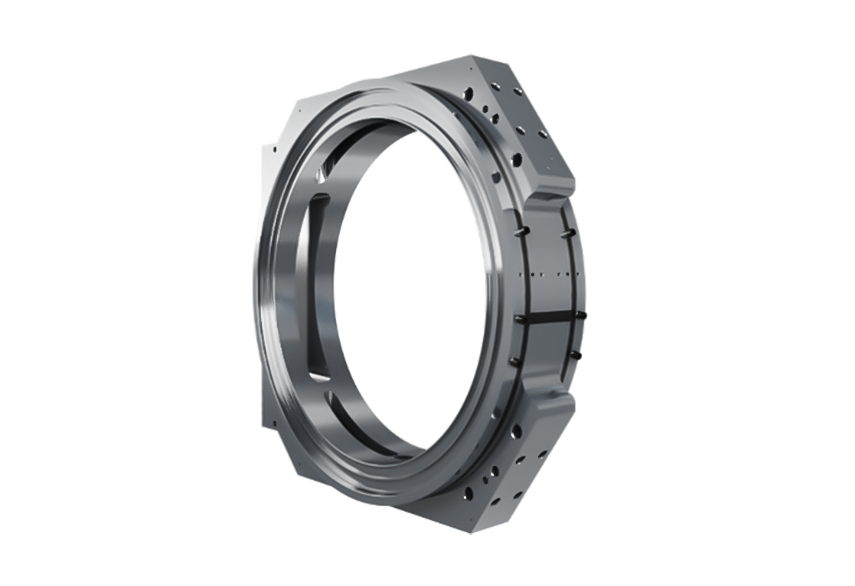

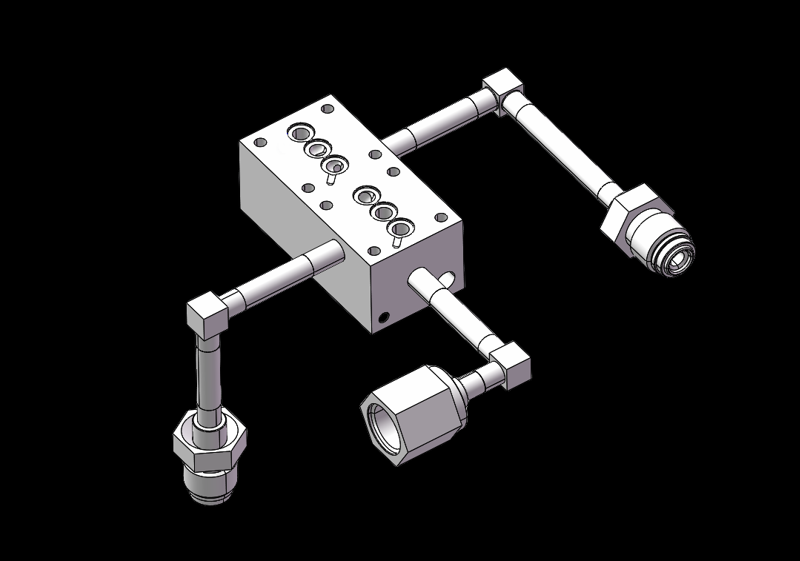

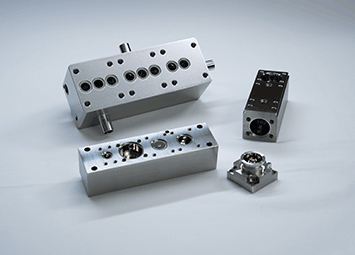

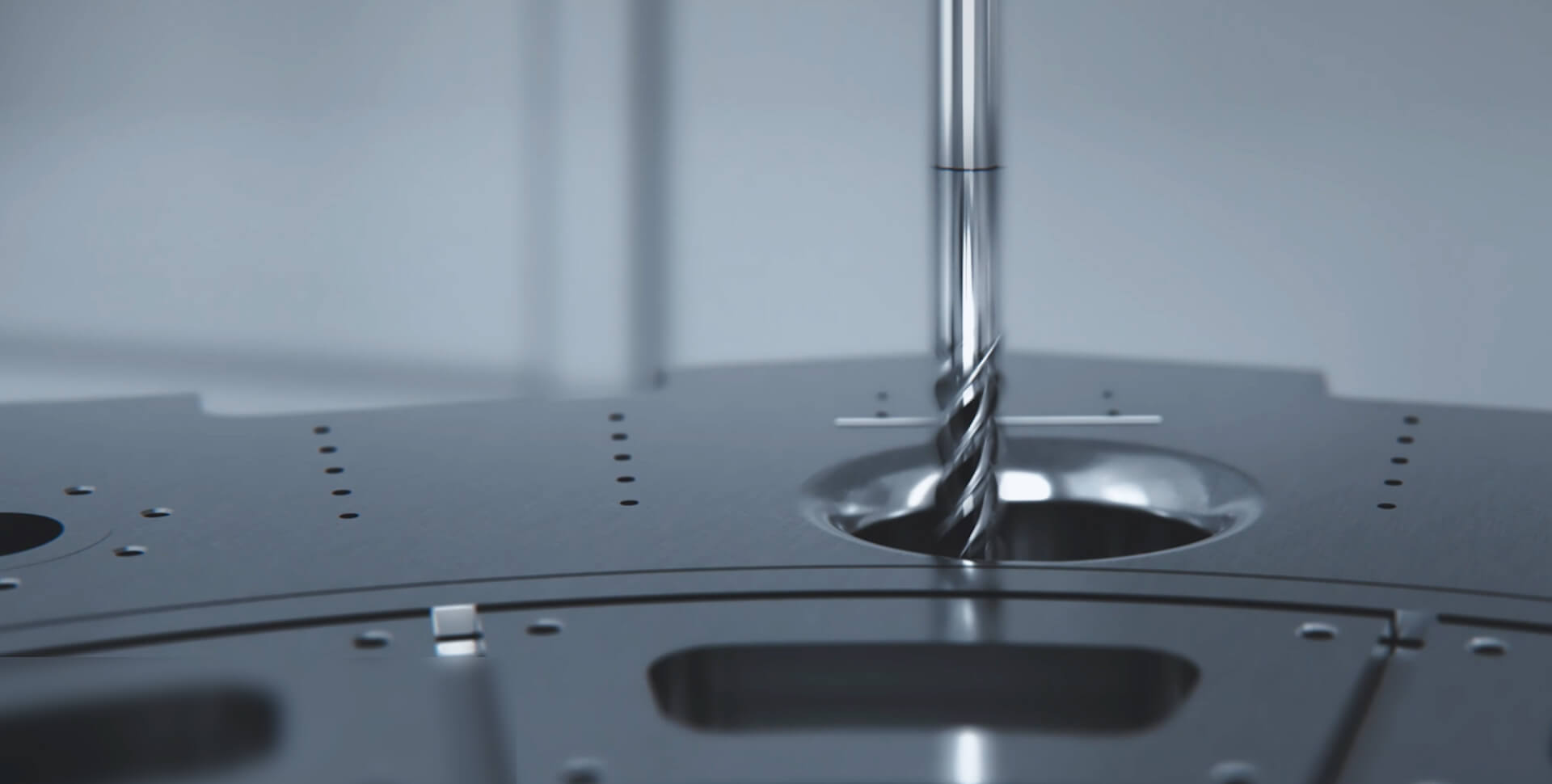

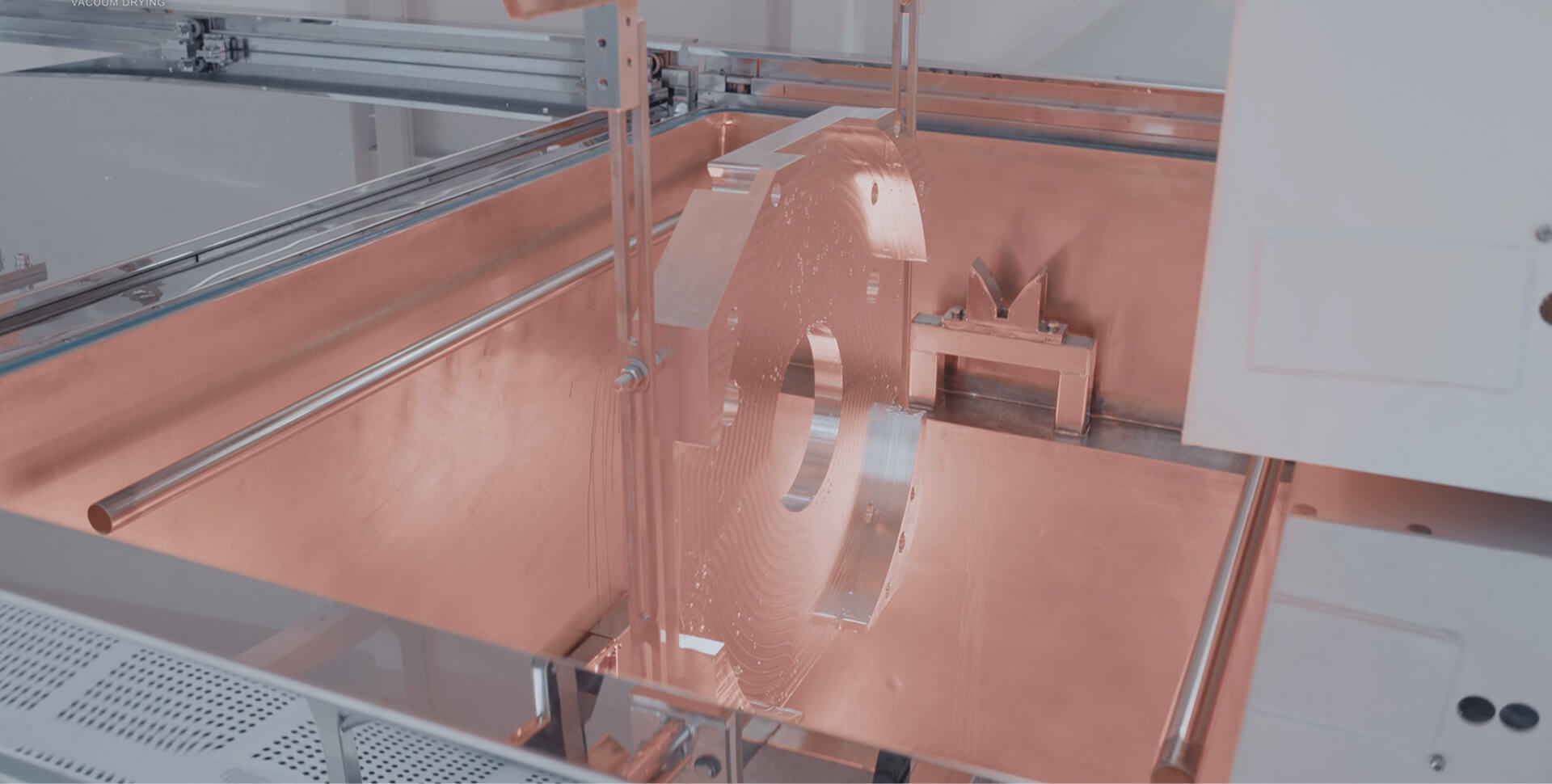

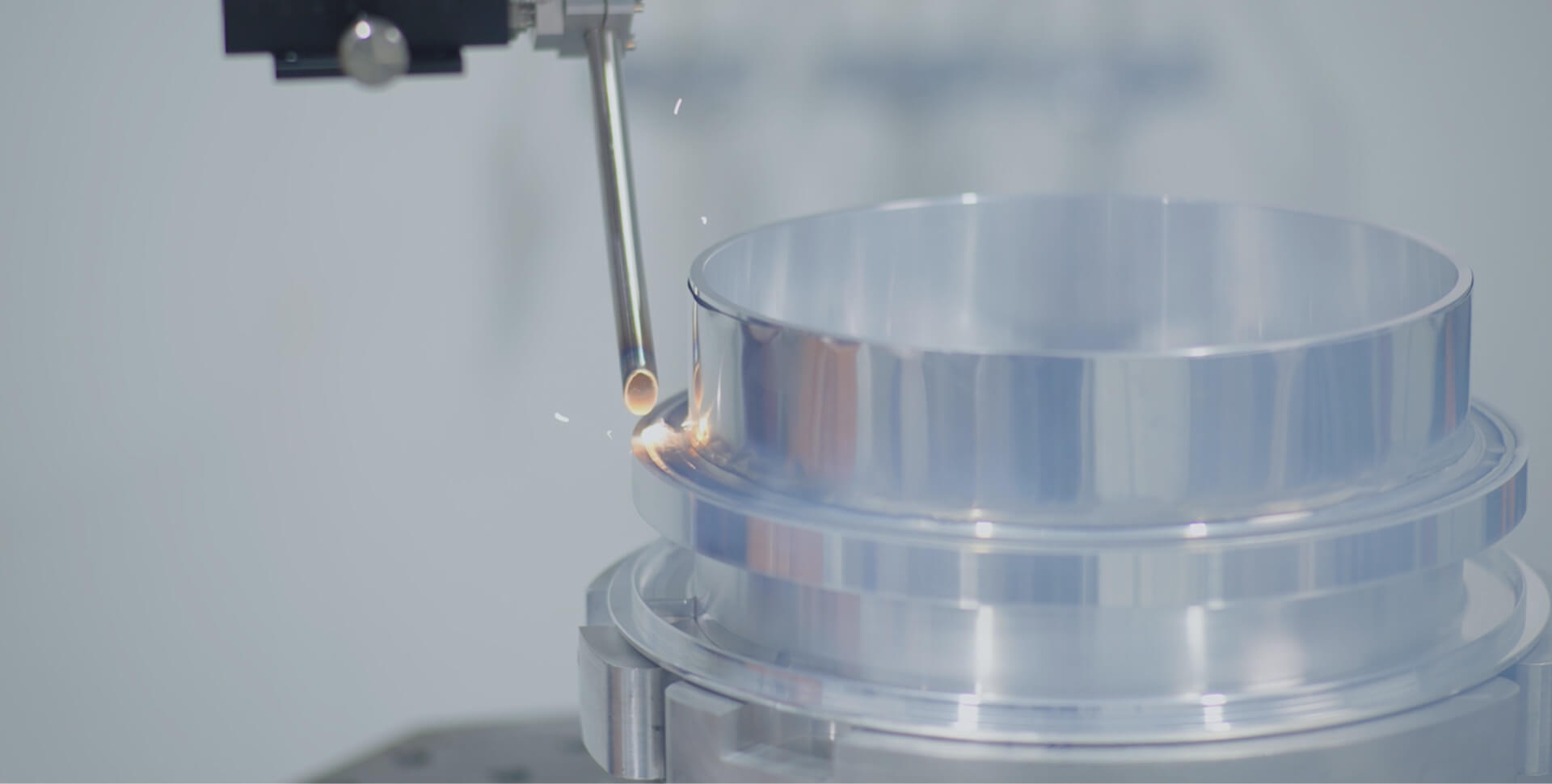

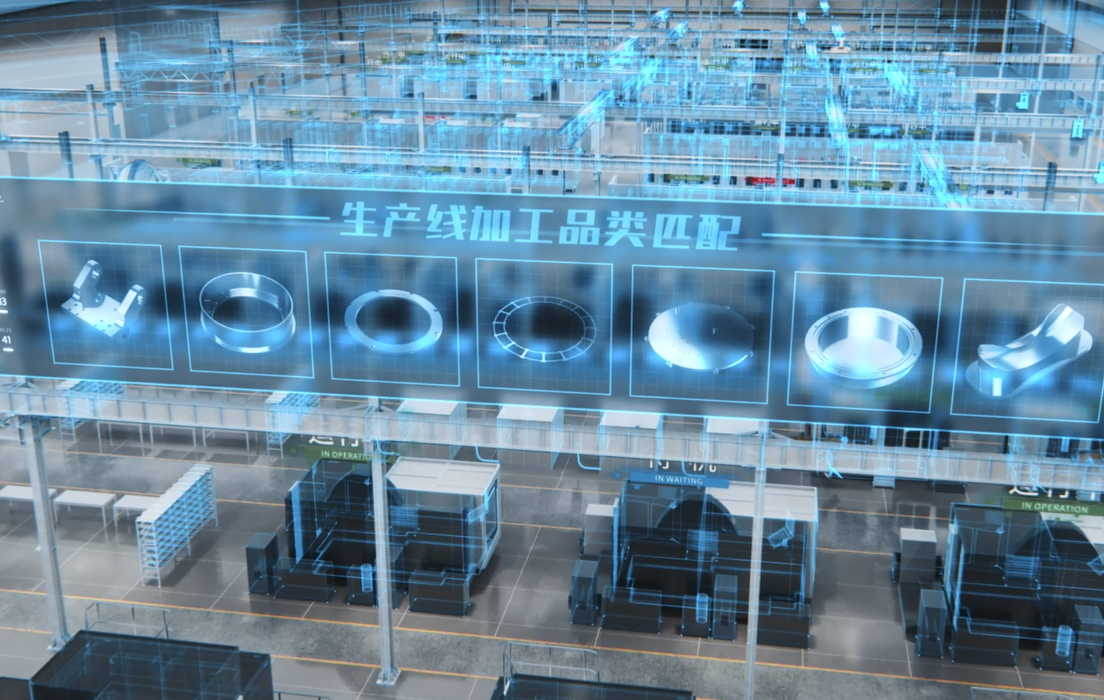

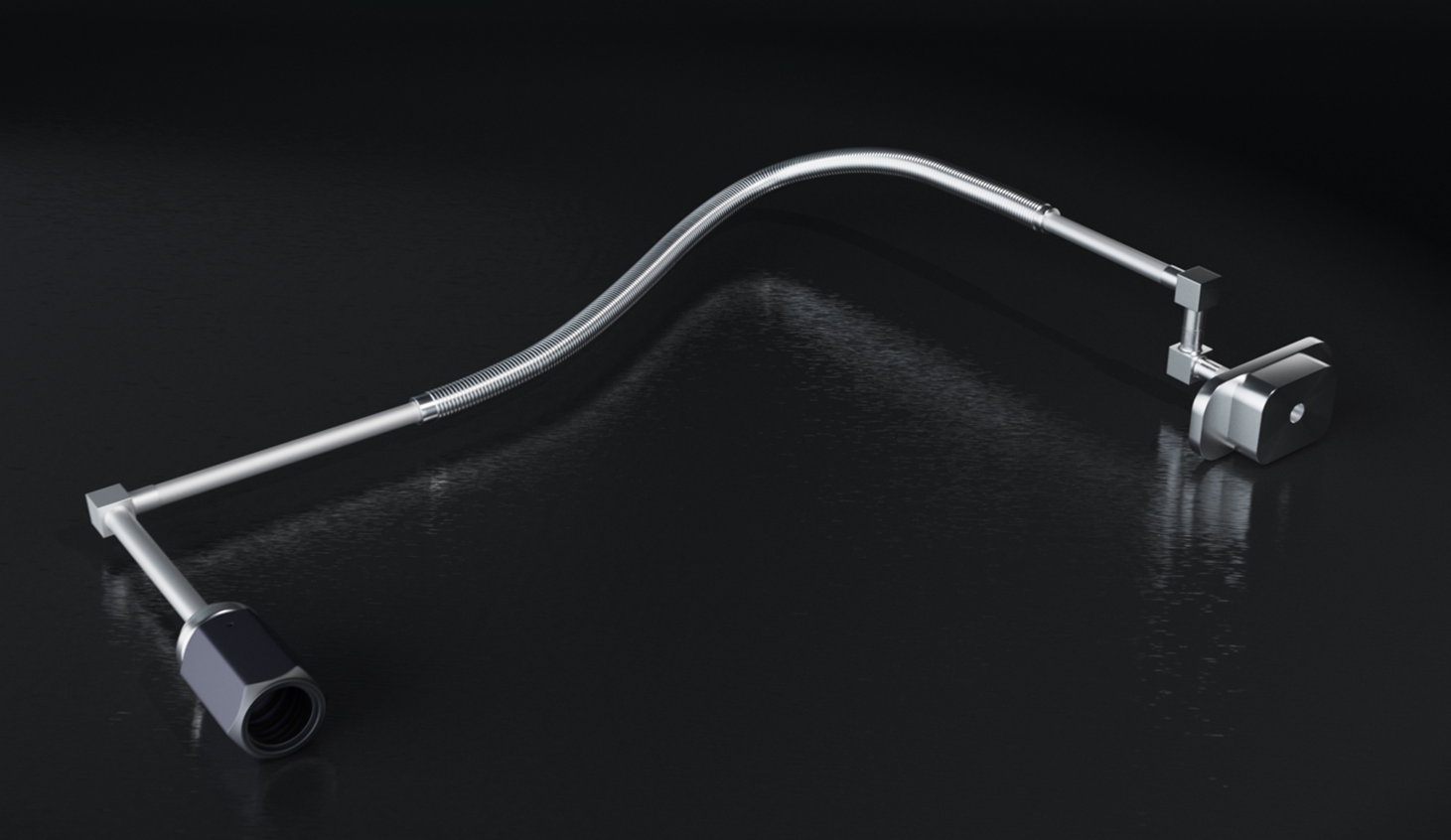

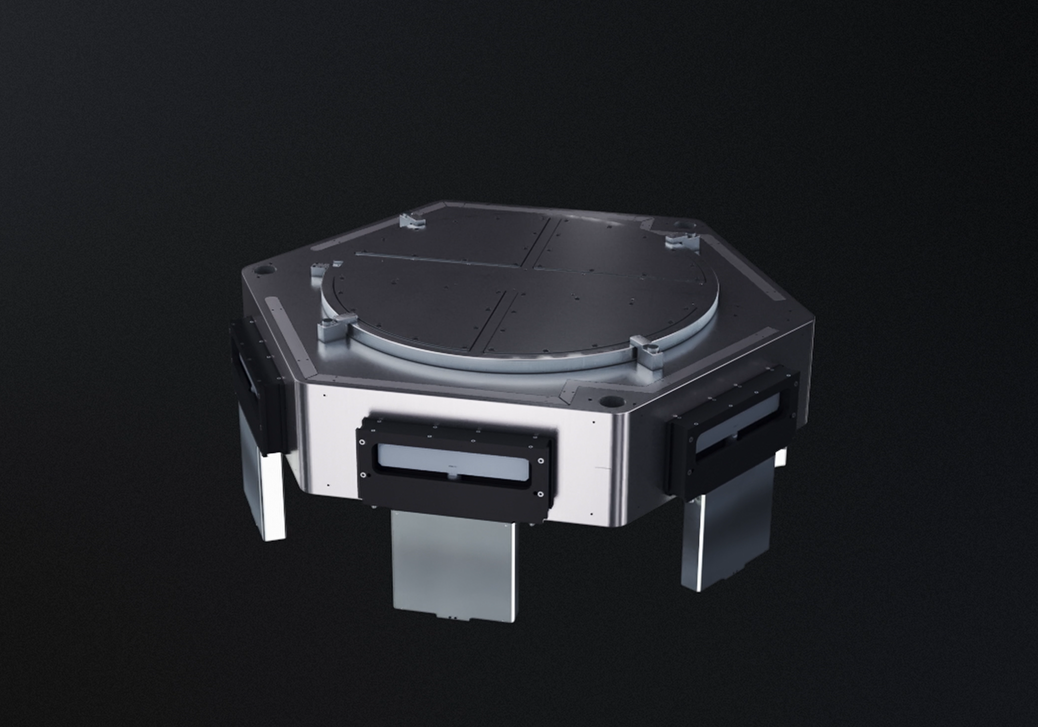

One-Stop Manufacturing

Fortune Precision is one of the few multi-product category suppliers in the global semiconductor industry, possessing one-stop vertical integration service capabilities. Providing global clients with refined management throughout the entire product lifecycle.