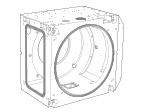

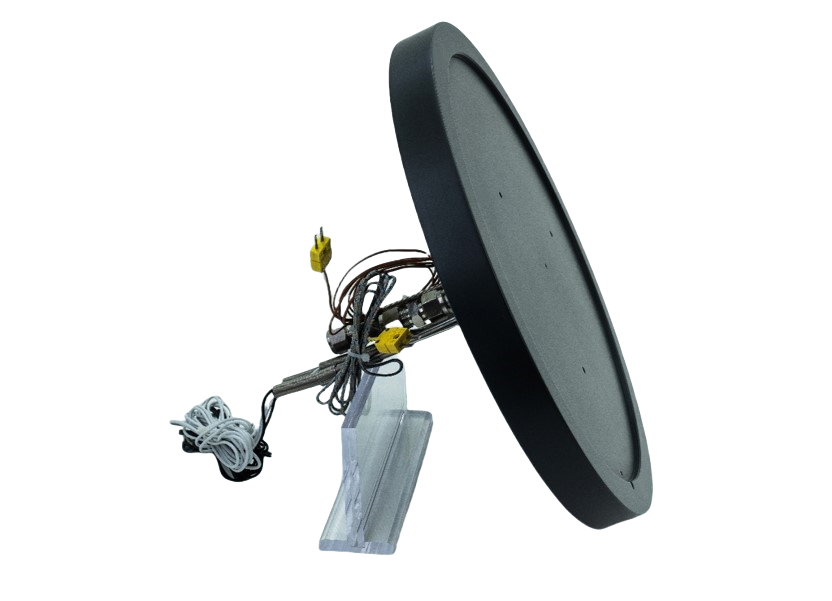

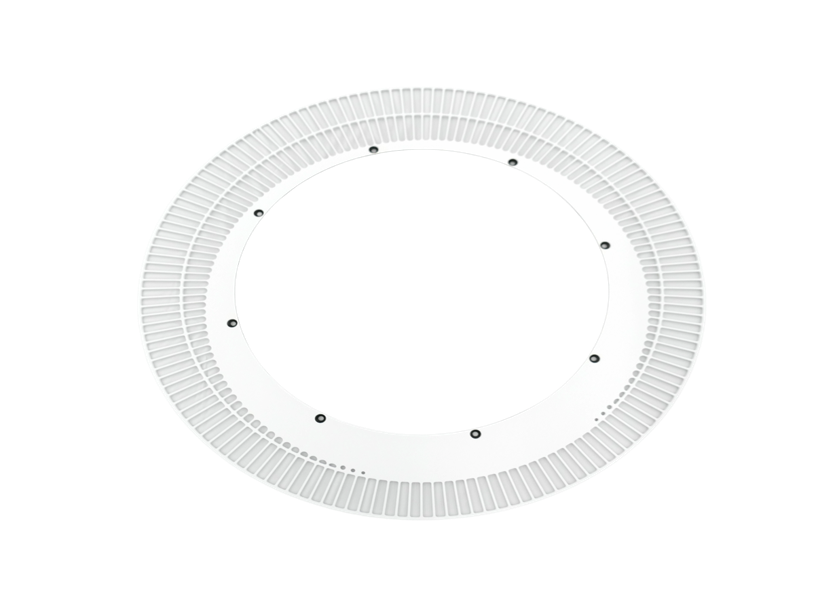

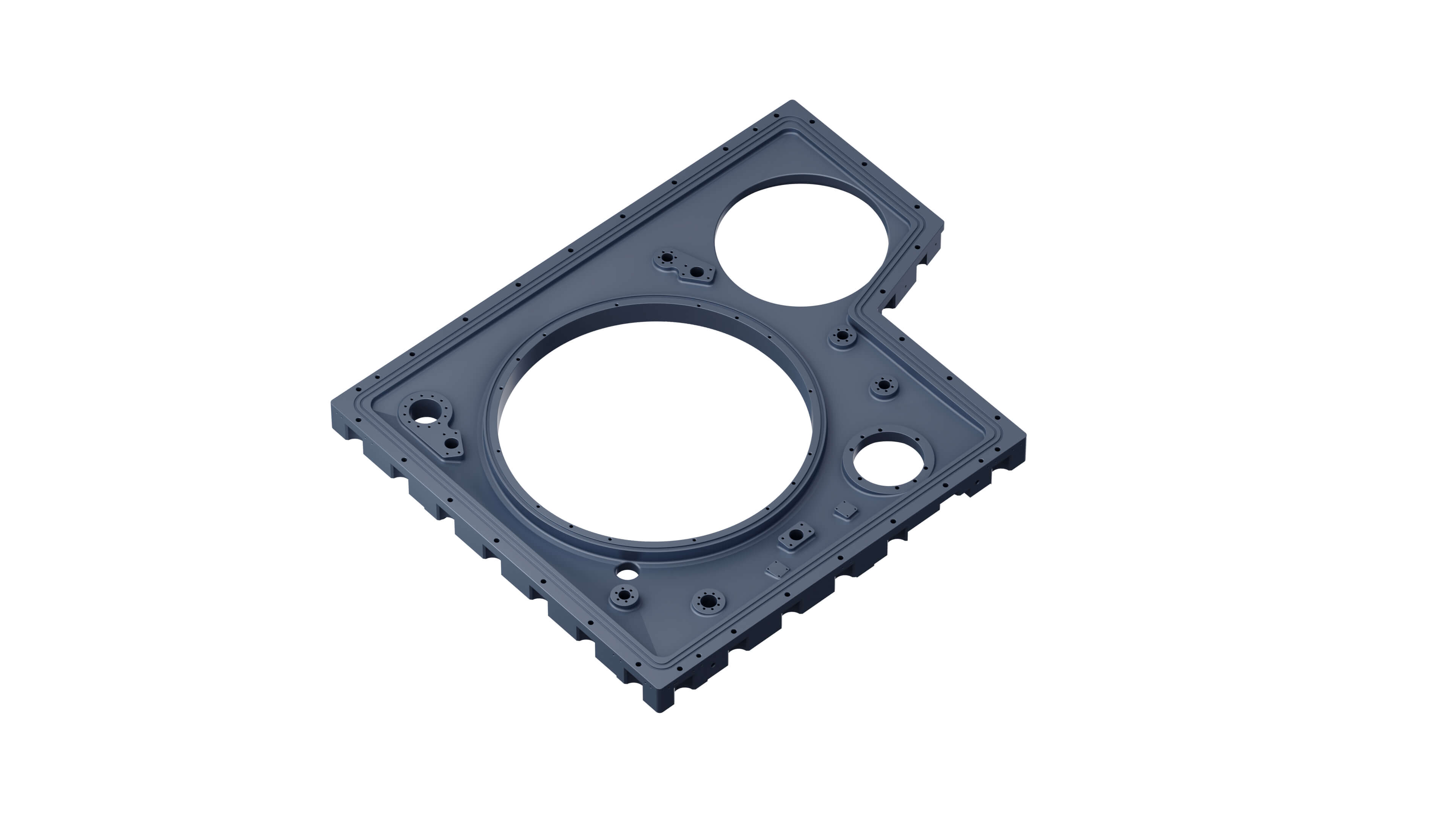

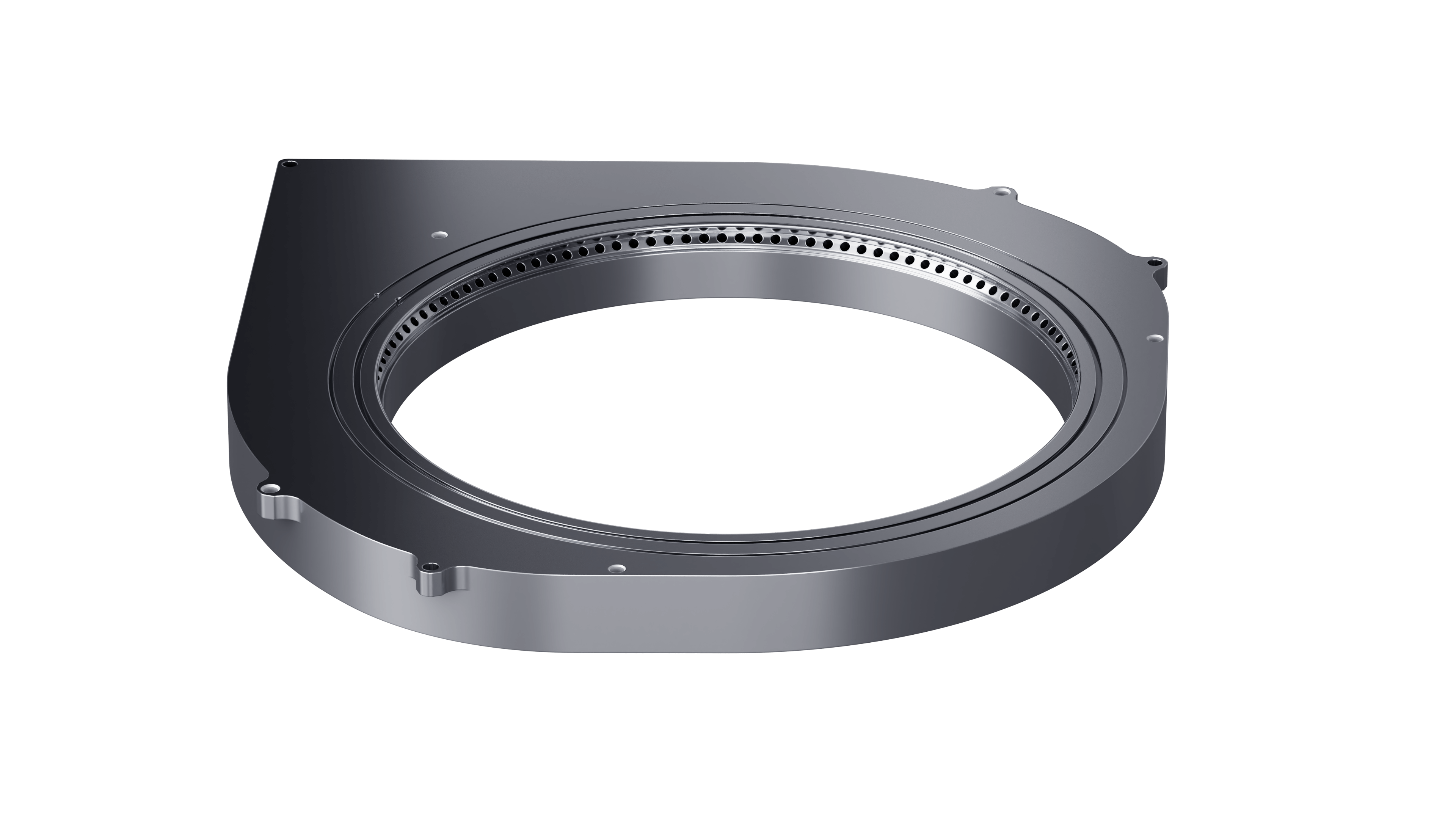

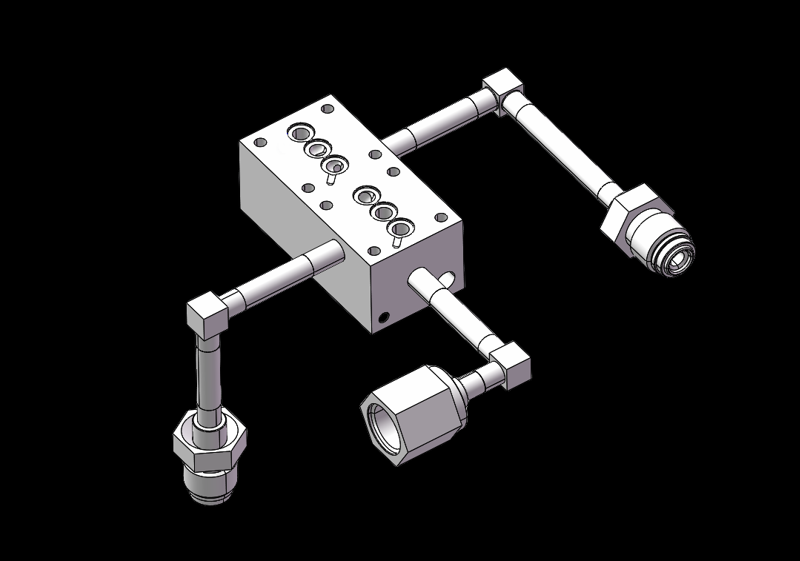

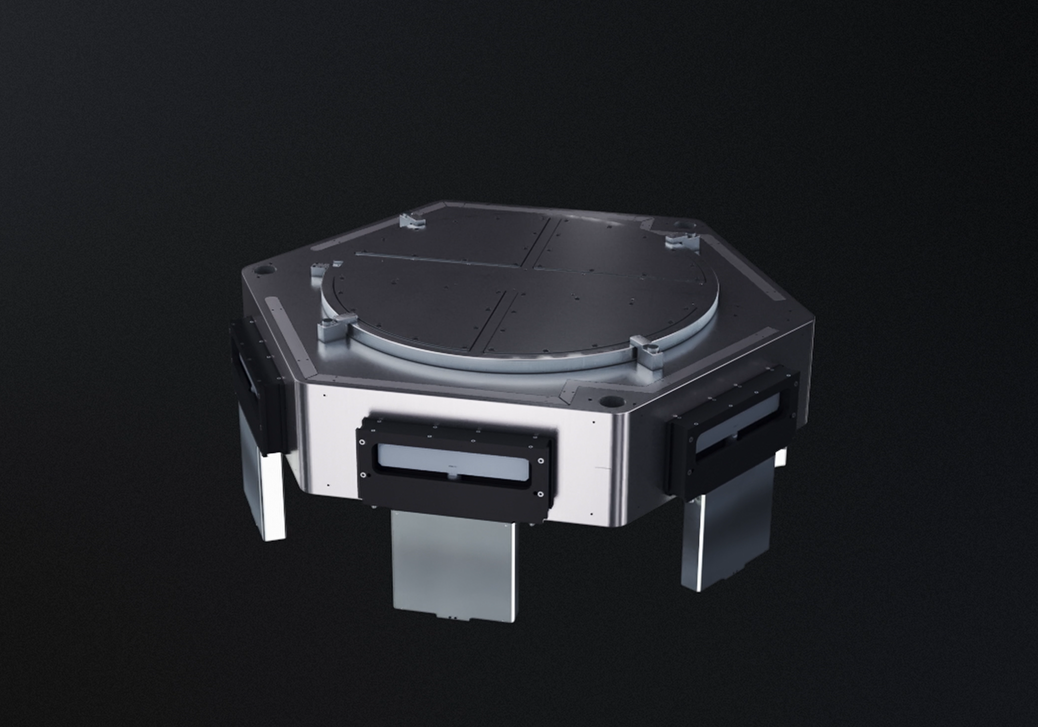

Transfer Chamber Module

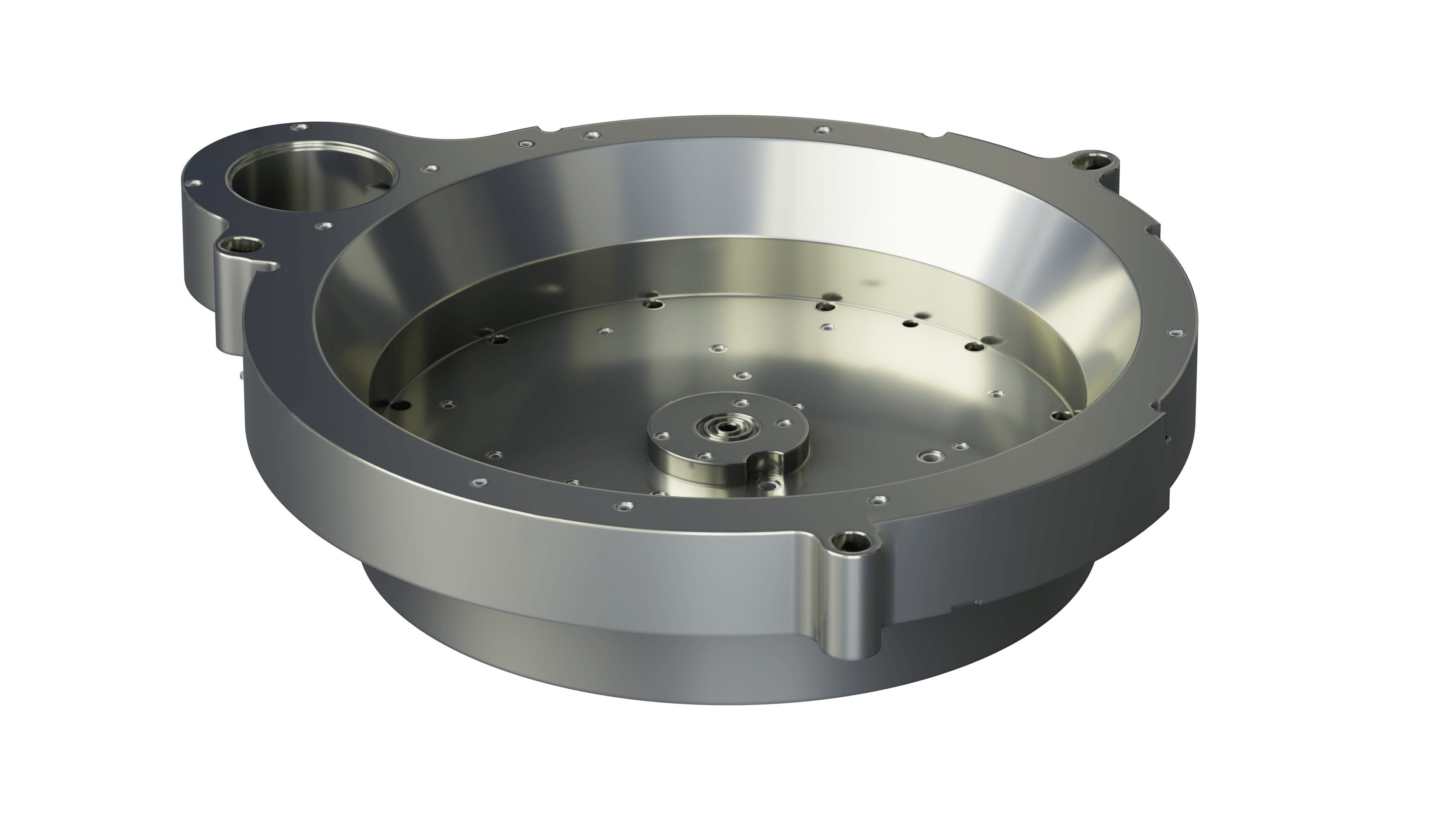

Transfer chamber modules are used in vacuum process equipment such as etching and thin film deposition, with the core function of transferring wafers between the load module and the reaction module.

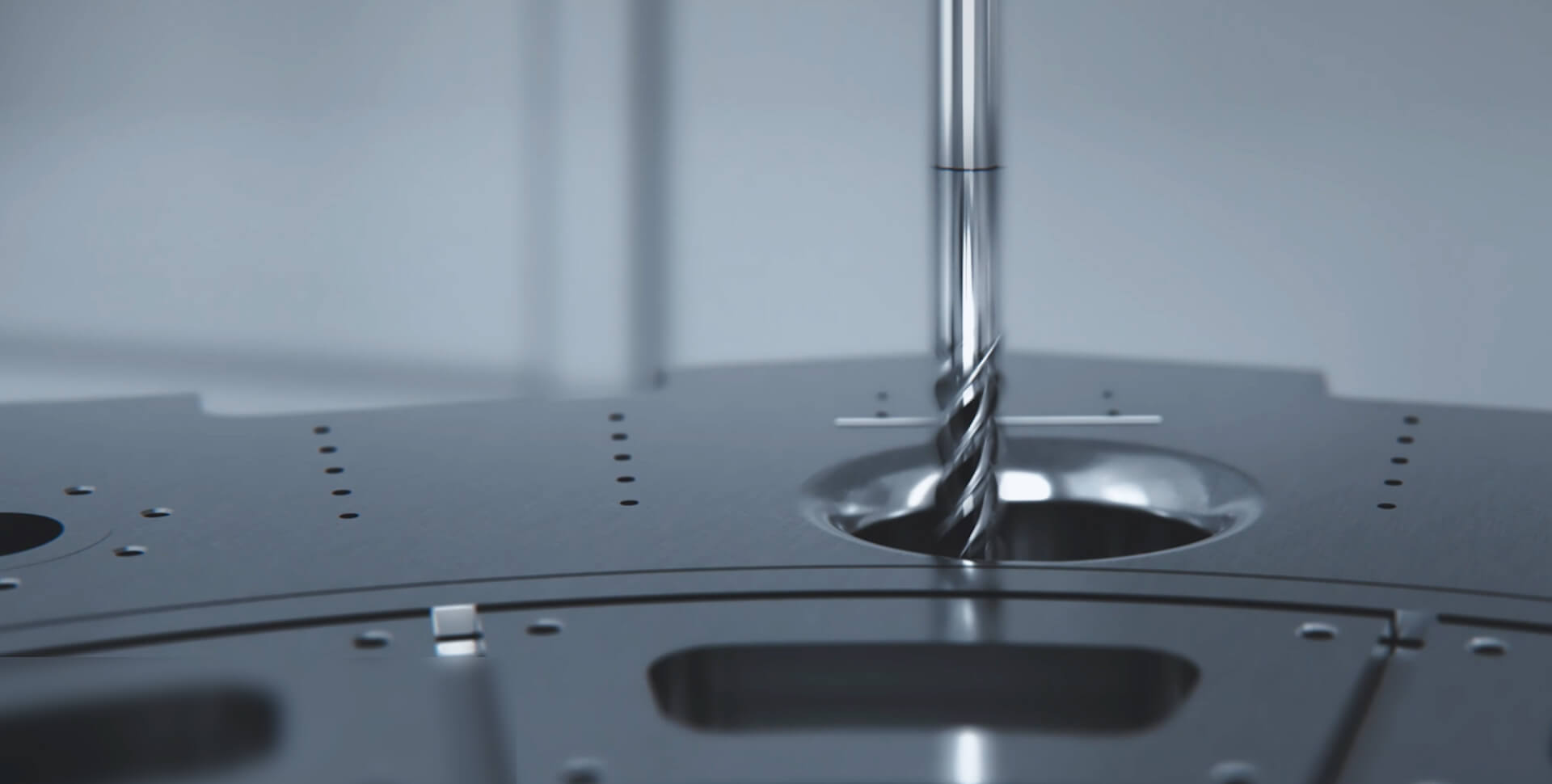

The overall performance of the company's transfer chamber modules is certified by major international clients. Leveraging precision machining, ultra-clean cleaning, and advanced assembly and testing techniques, the modules are engineered to ensure optimal cleanliness, sealing integrity, and motion characteristics.

Consult an Expert

Consult an Expert

-

Product Characteristics

-

Product Parameters

-

Related Solutions

Product Characteristics

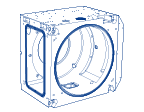

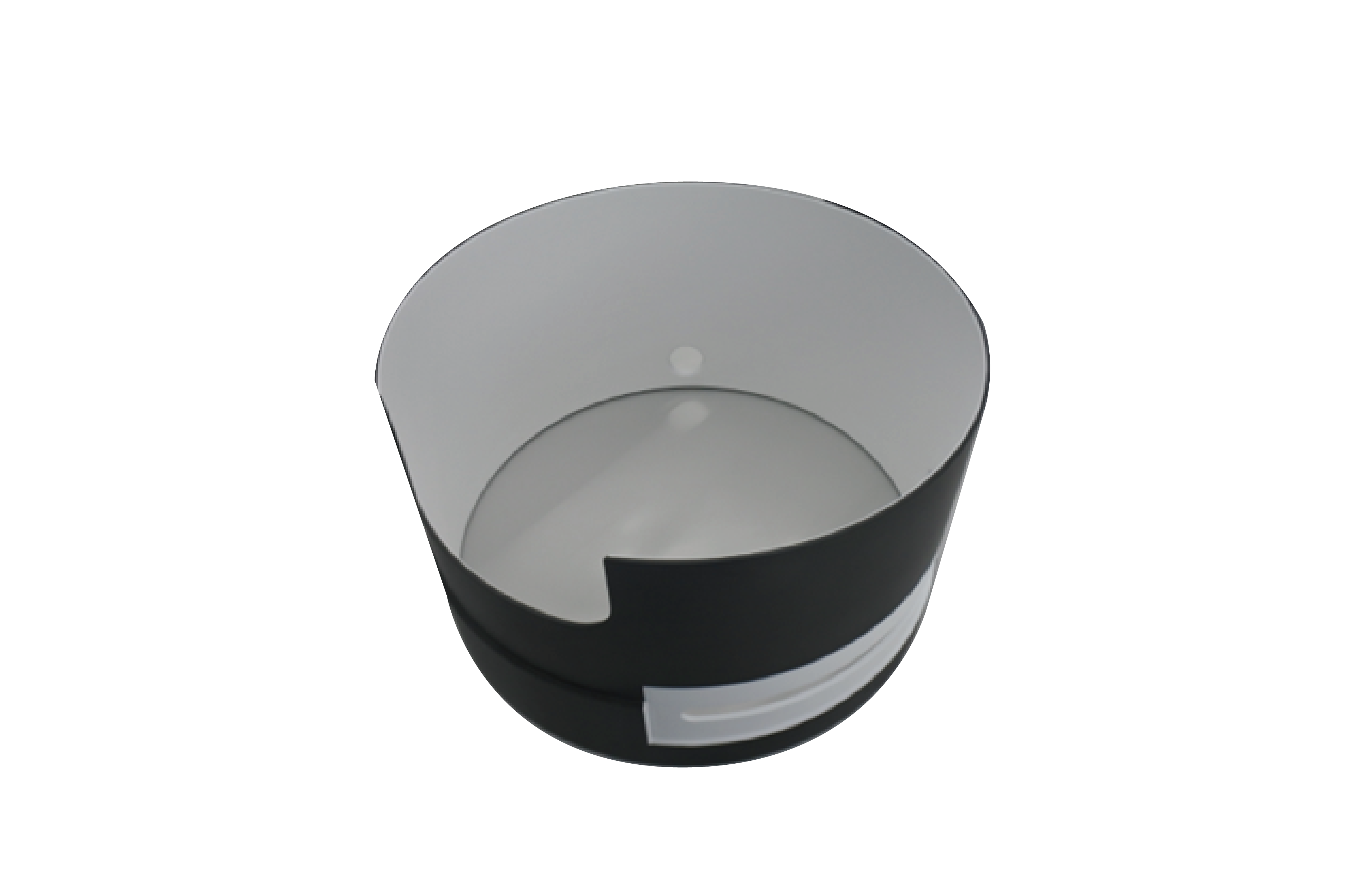

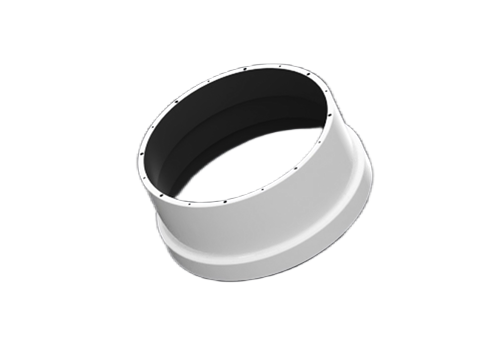

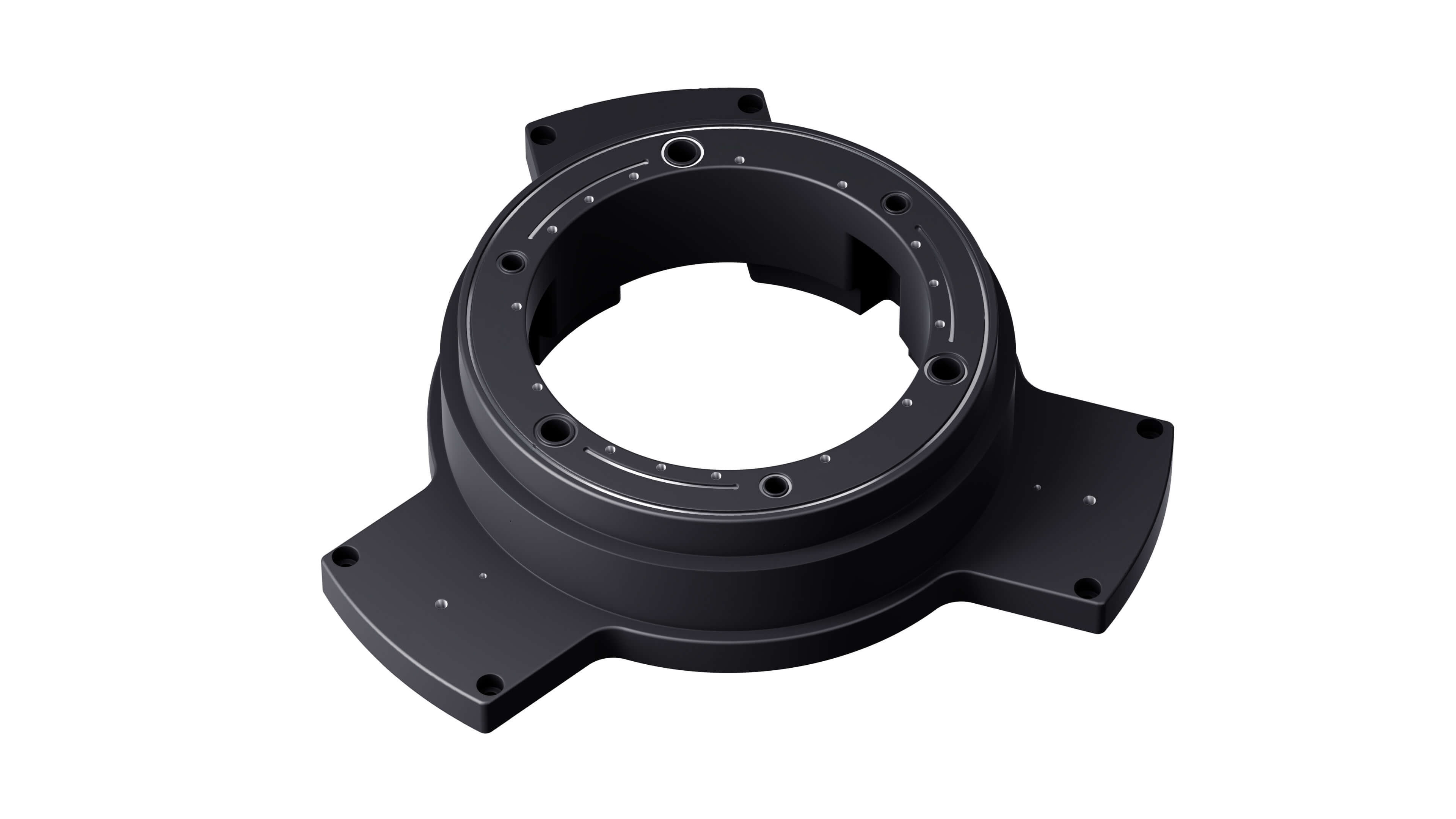

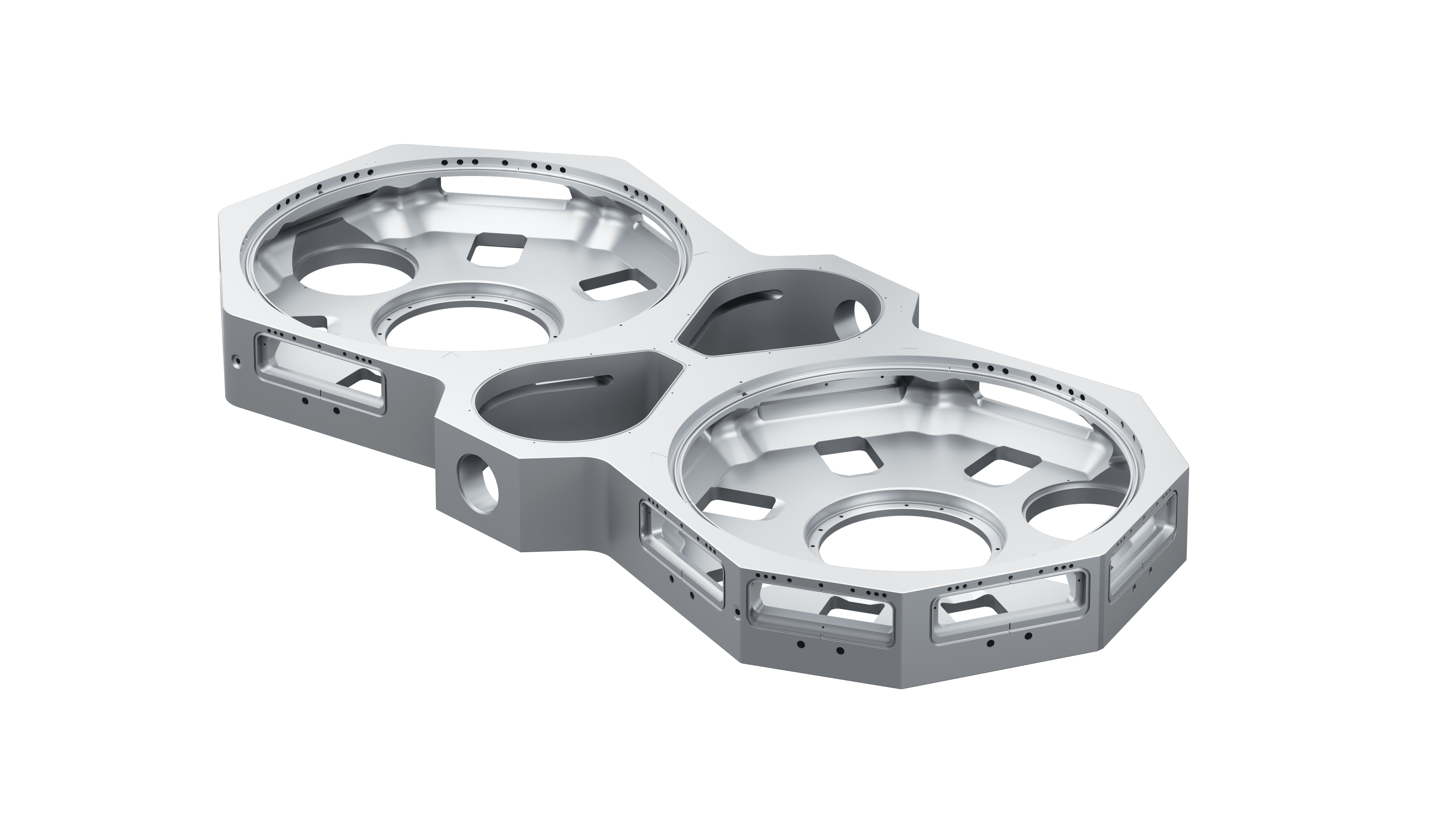

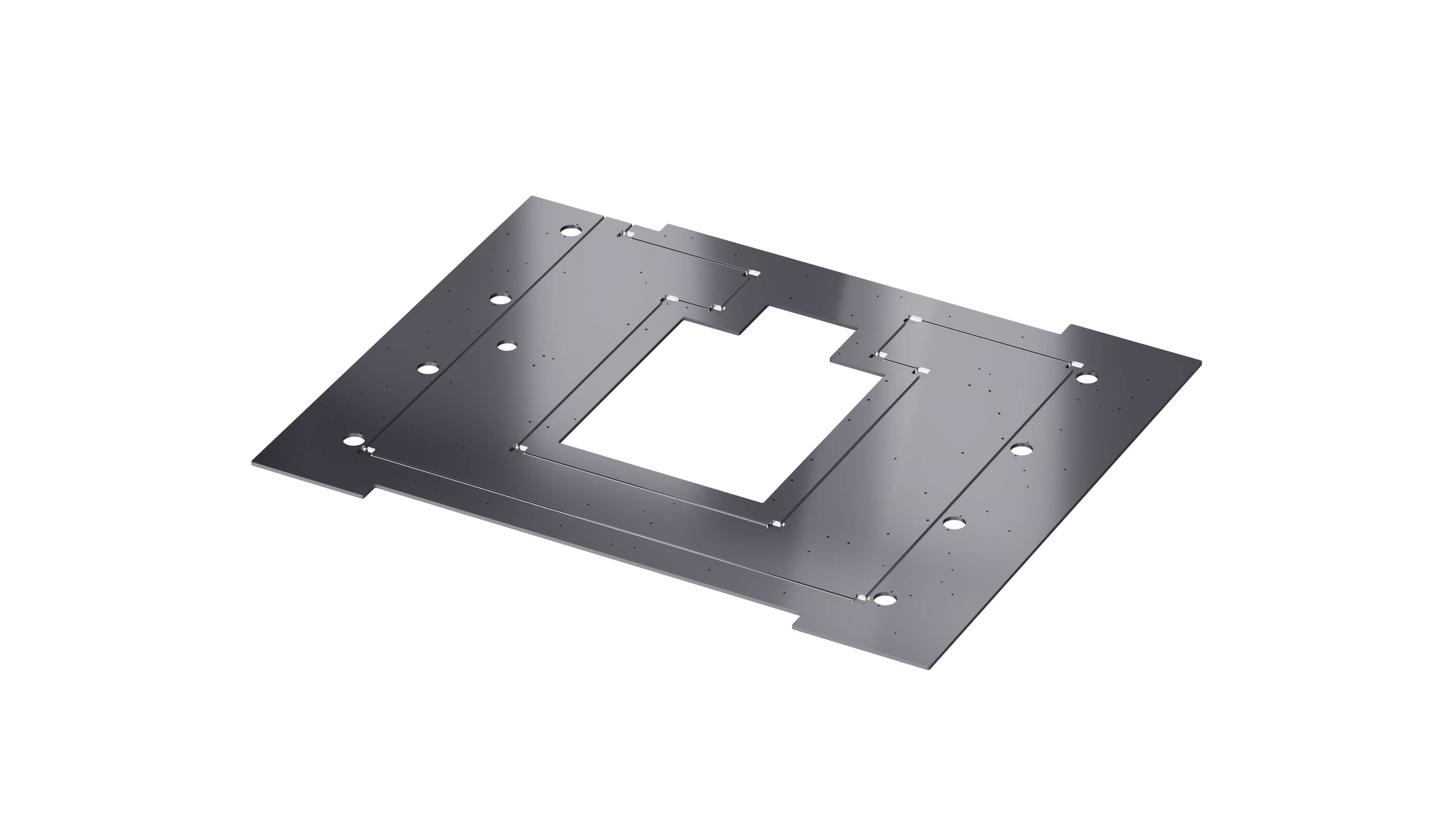

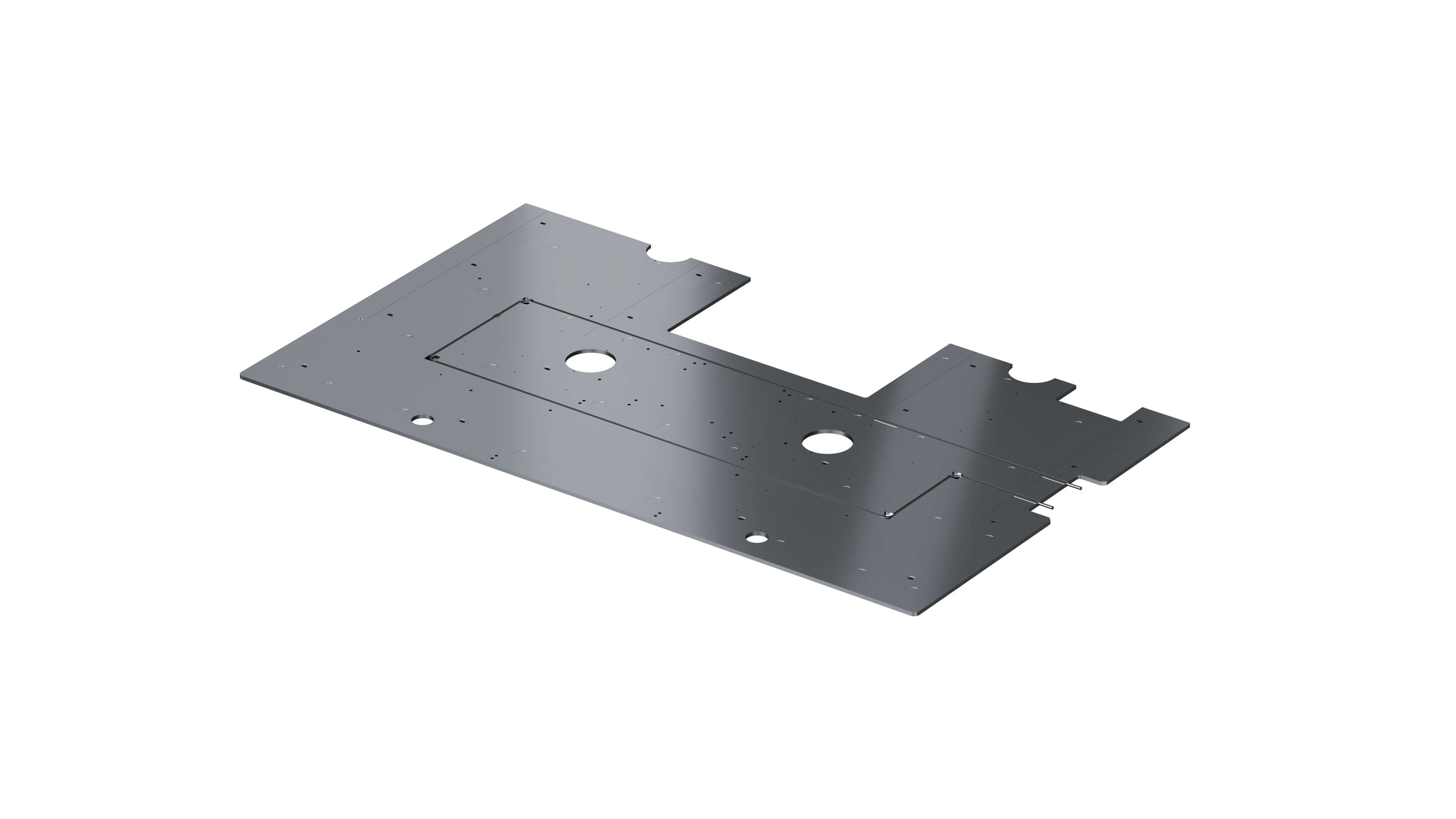

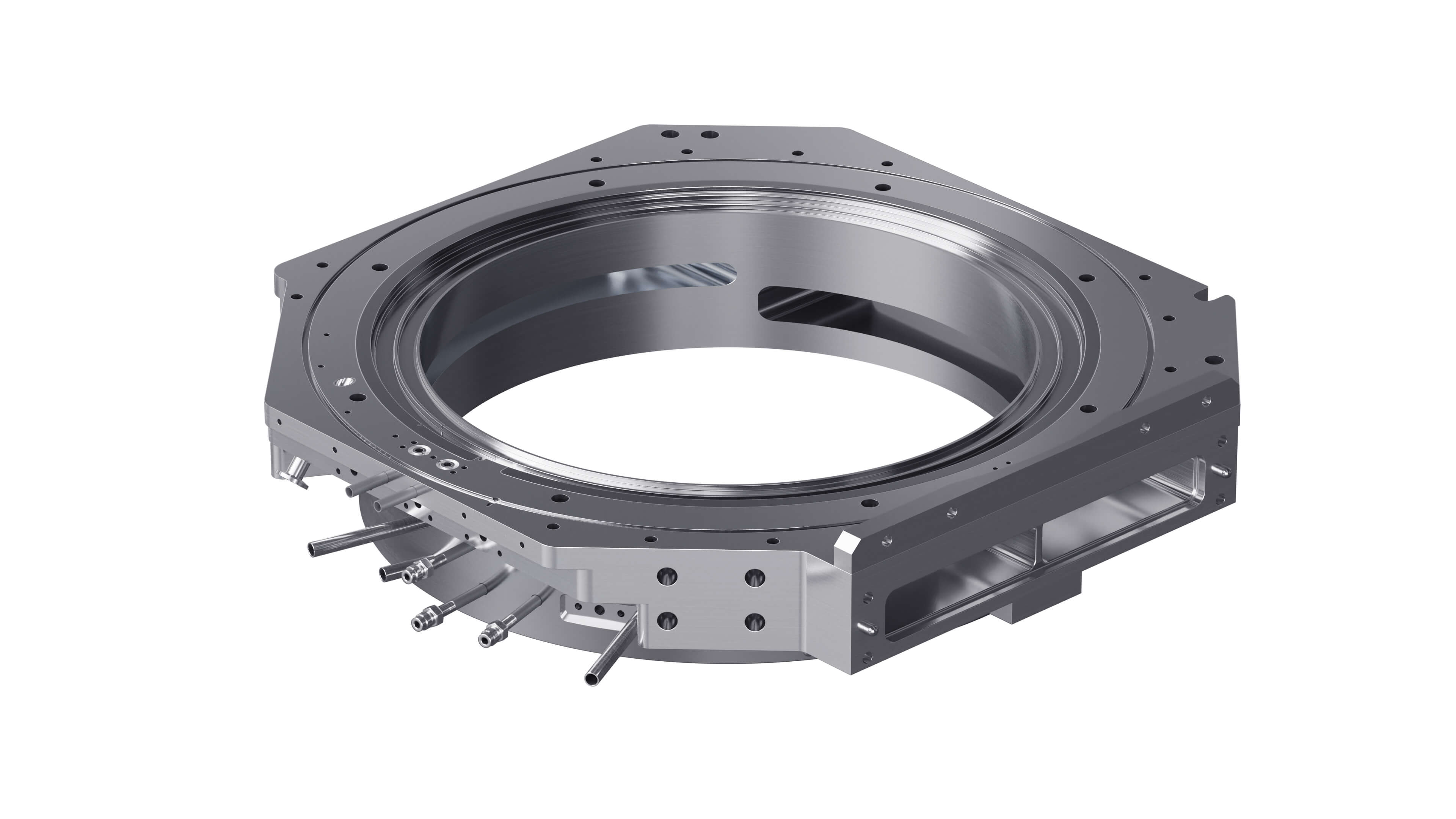

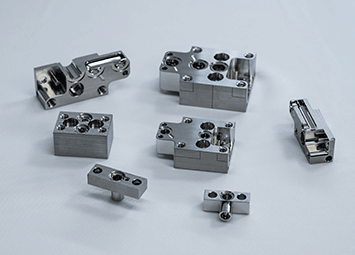

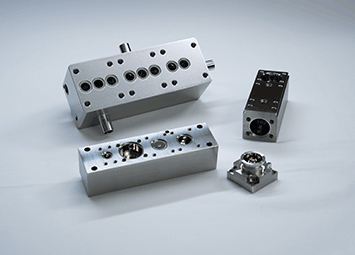

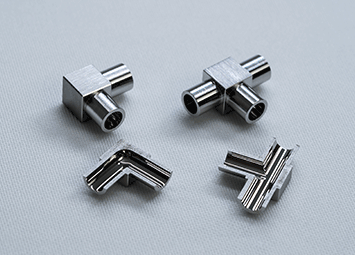

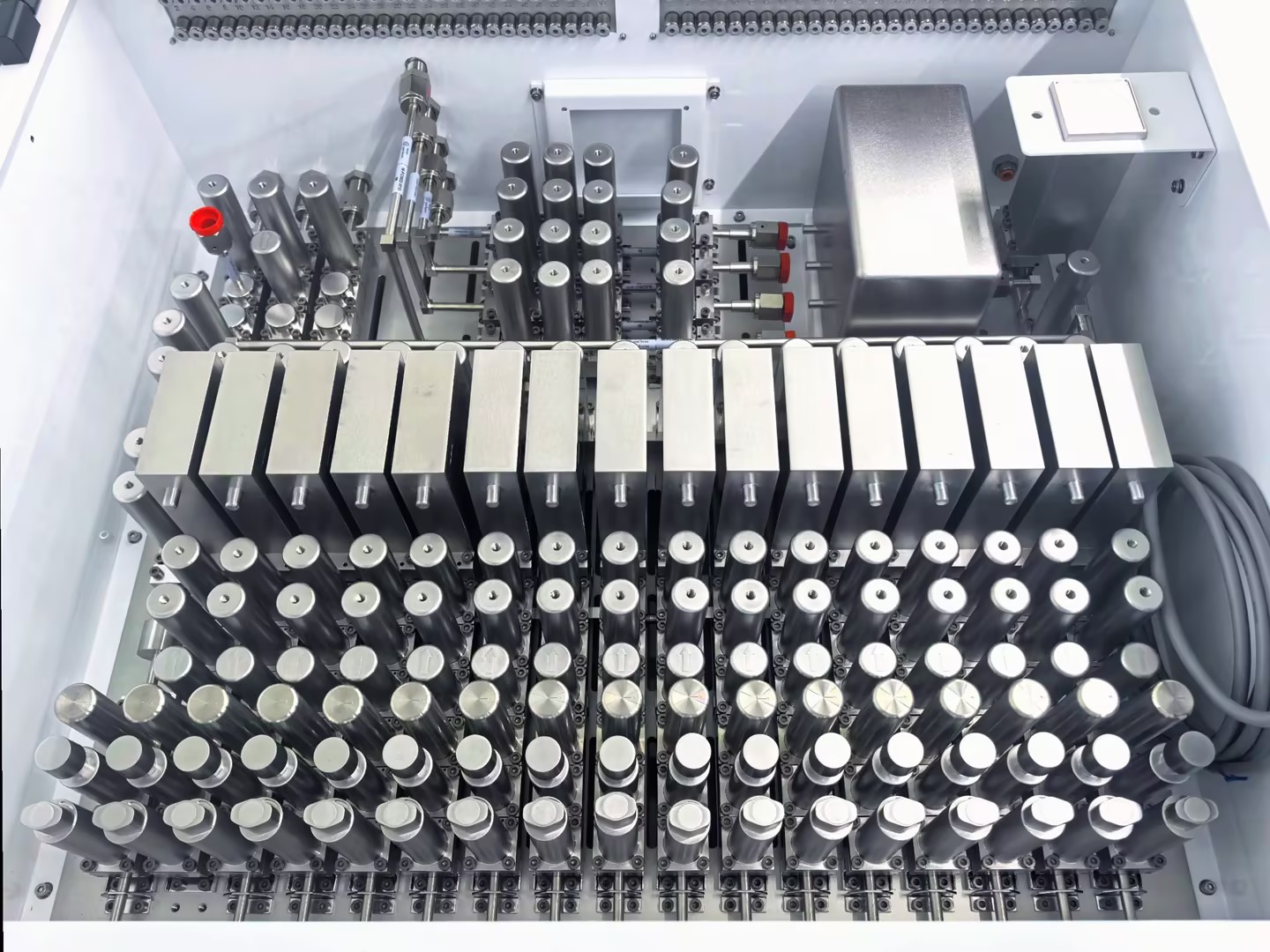

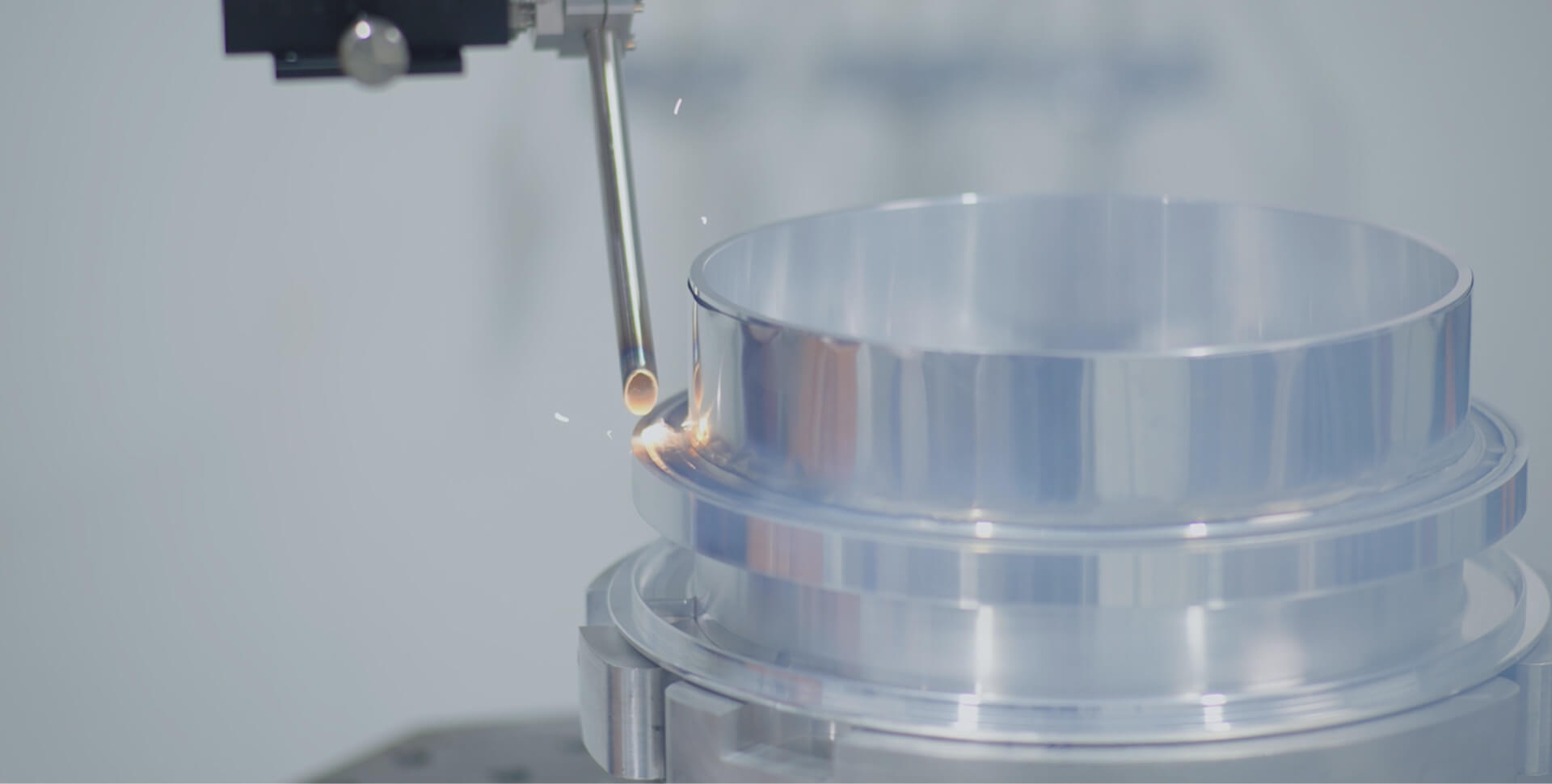

High Precision Complex Assembly Technology

Module production requires the completion of sealed assembly, electrical assembly, and moving parts assembly processes.

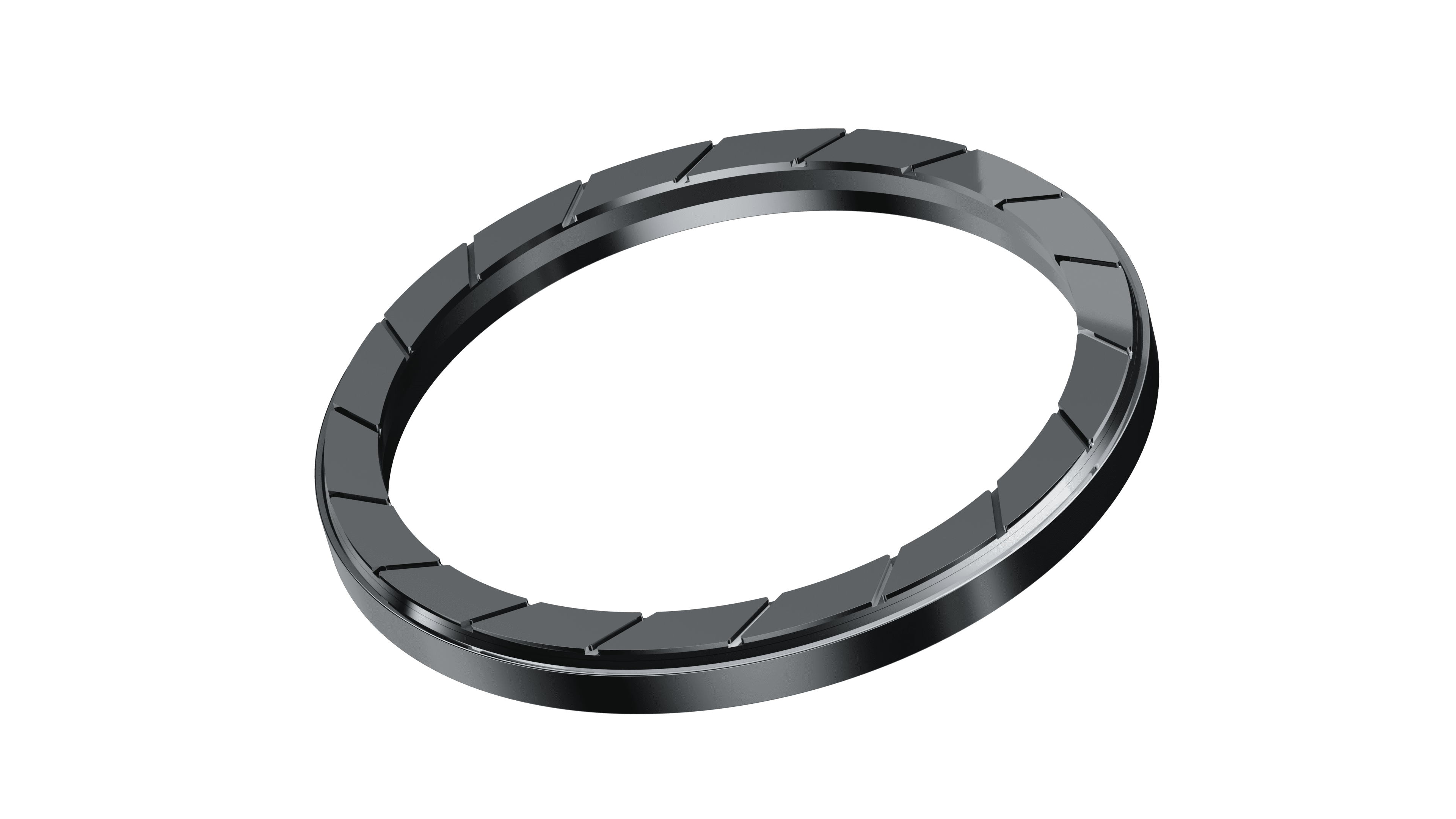

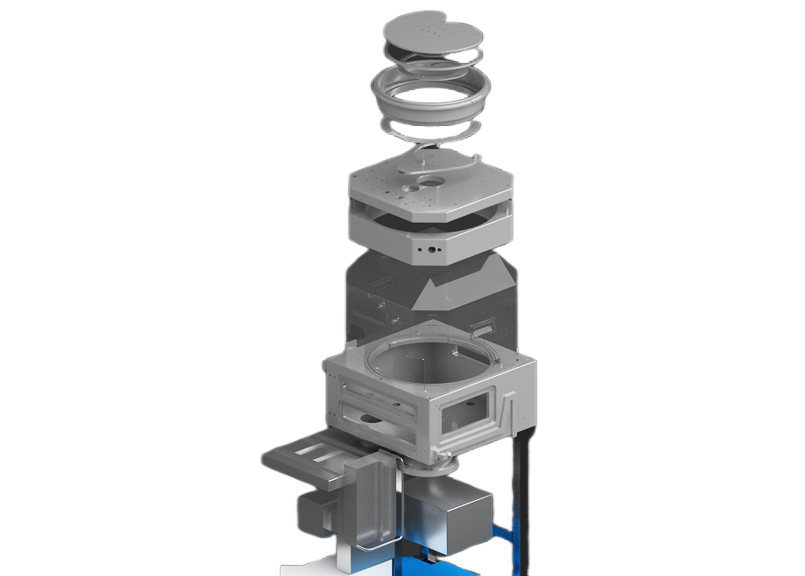

High Sealing Performance

The primary function of the transfer chamber module is to transfer wafers between the load module and the reaction module; ensuring effective sealing is crucial for maintaining wafer quality.

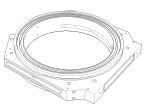

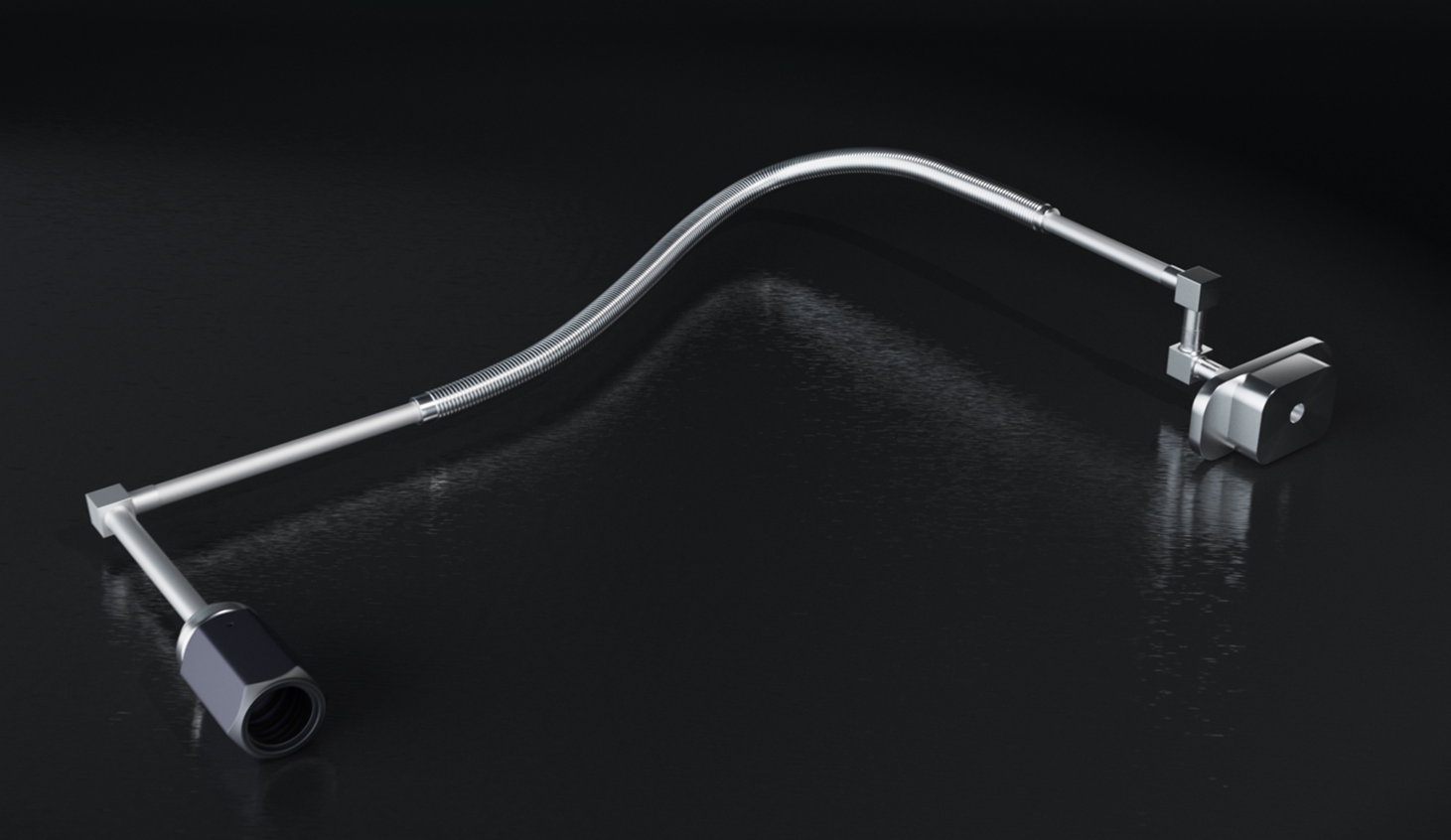

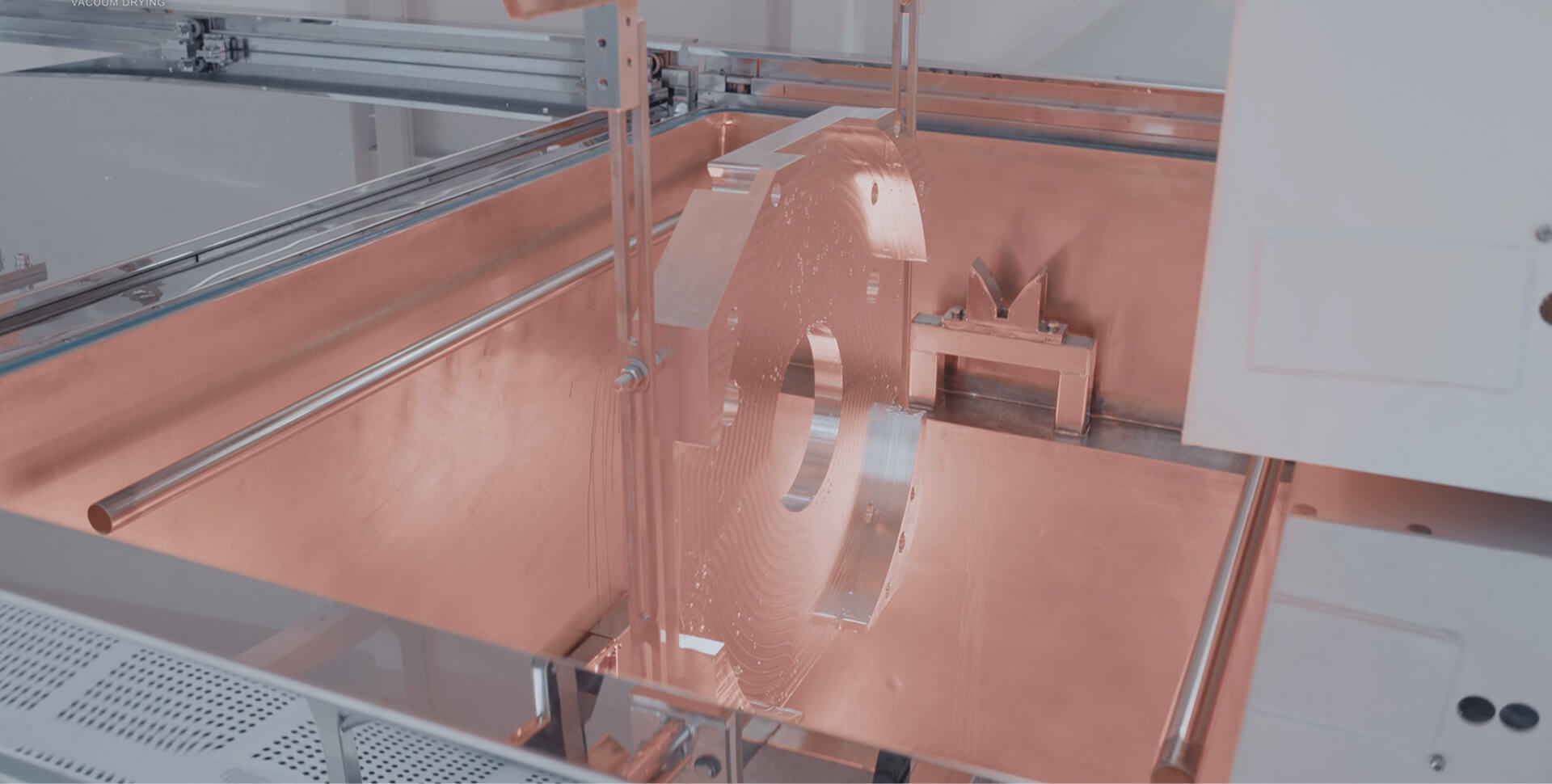

High Cleanliness

High-cleanliness equipment components are fundamental for achieving high yield rates in wafer processing. The cleanliness of process equipment directly determines the yield rate of wafers in process and subsequent chips, even determining if an entire production line can produce qualified products.

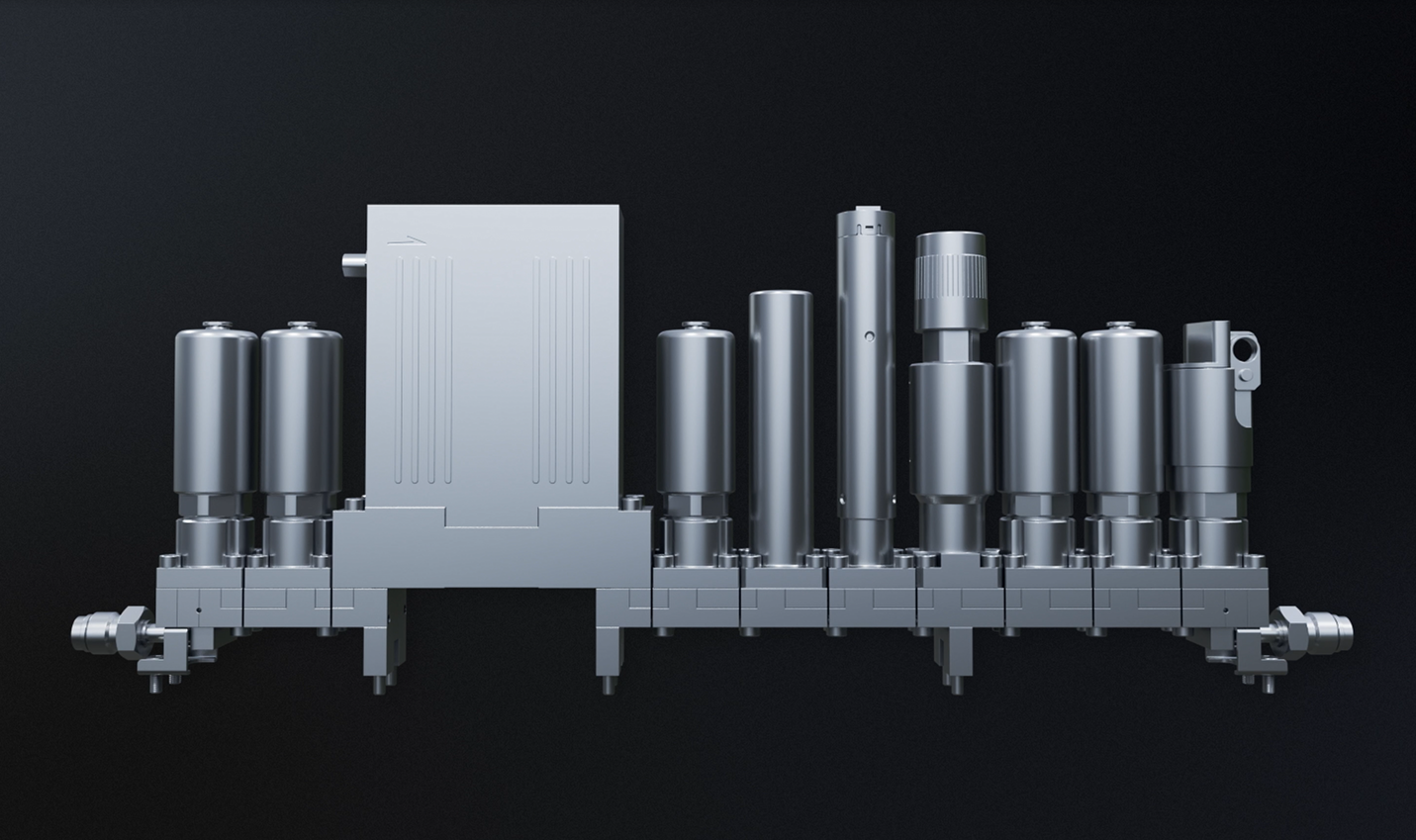

Product Parameters

| Composition: | Process Components, Structural Components, OEM Parts, Standard Parts |

| Leak Rate: | 1*10-9torr*l/s |

| Cleanliness: | Critical components undergo LPC (Liquid Particle Count) testing, ICP-MS metal element analysis, UV inspection. |