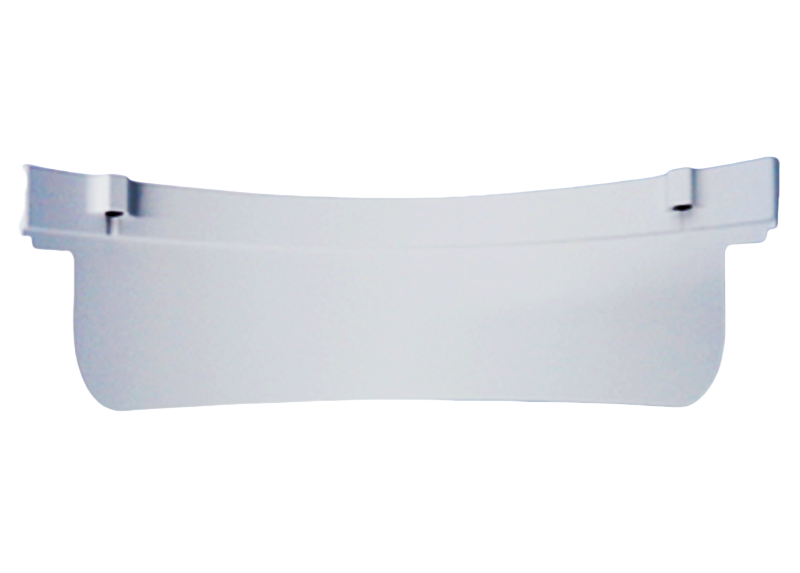

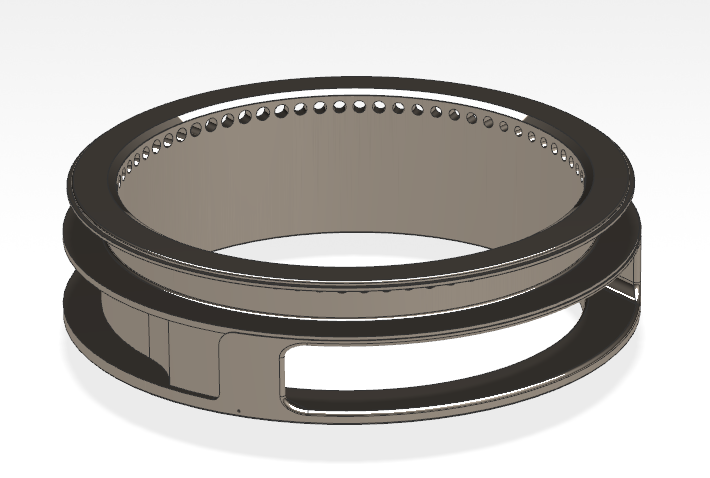

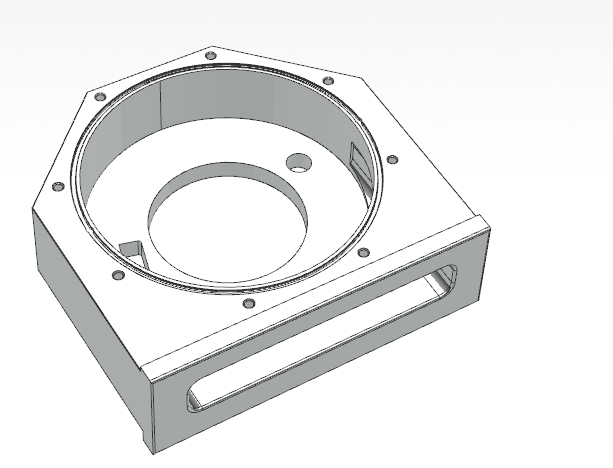

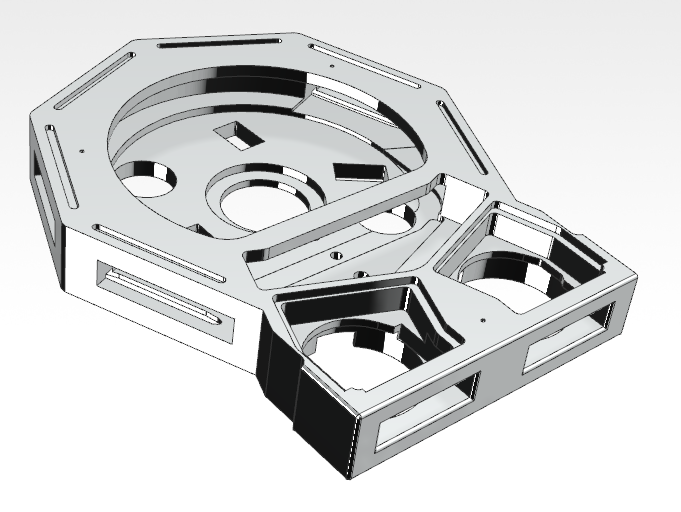

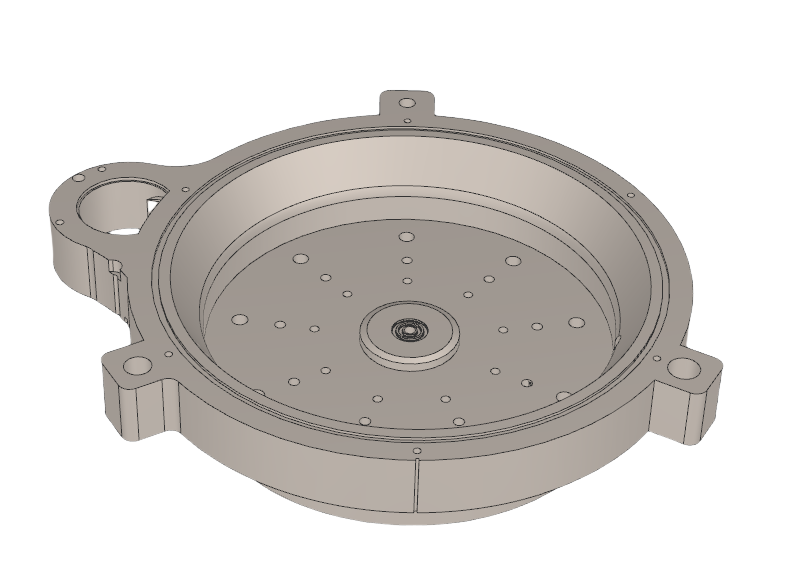

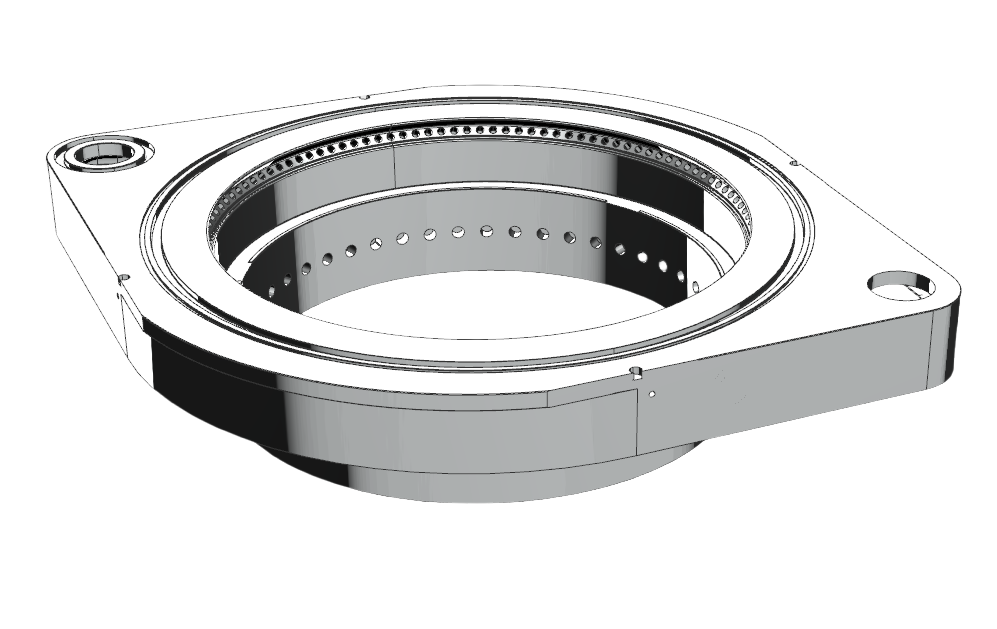

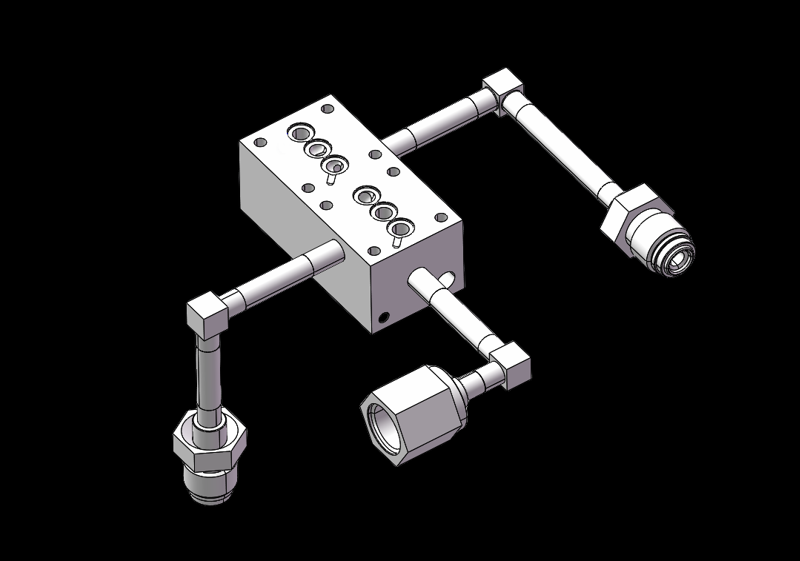

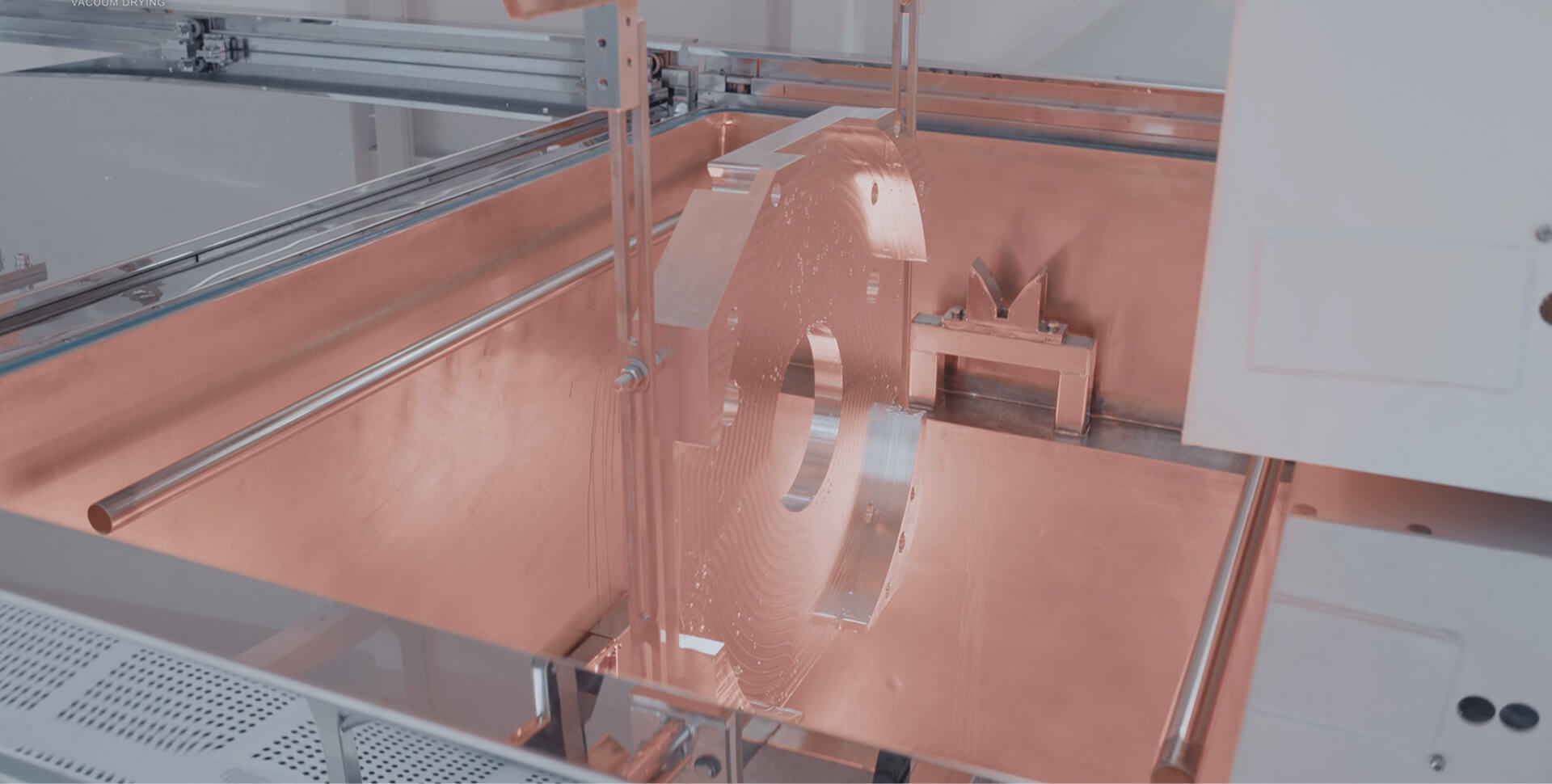

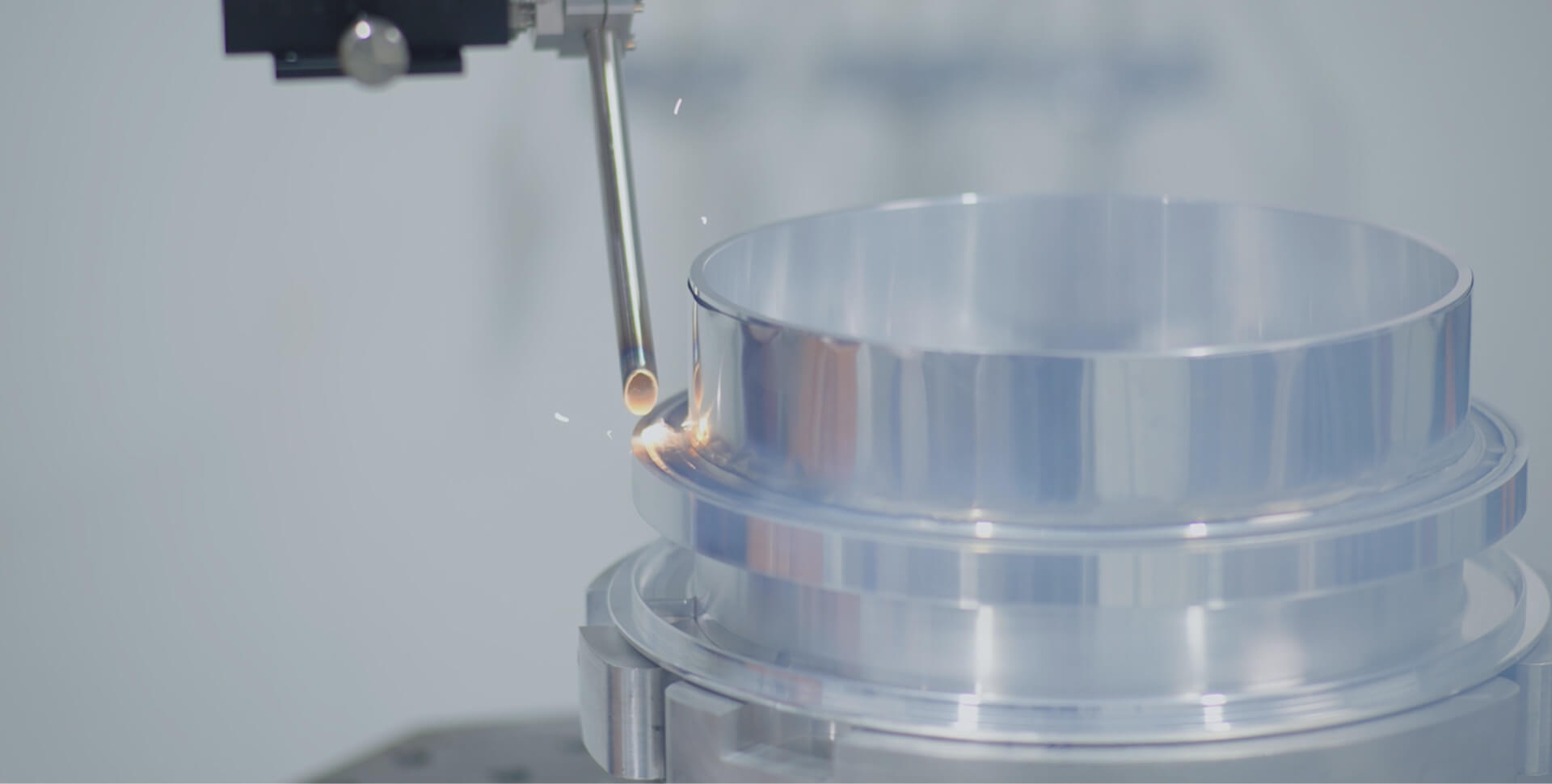

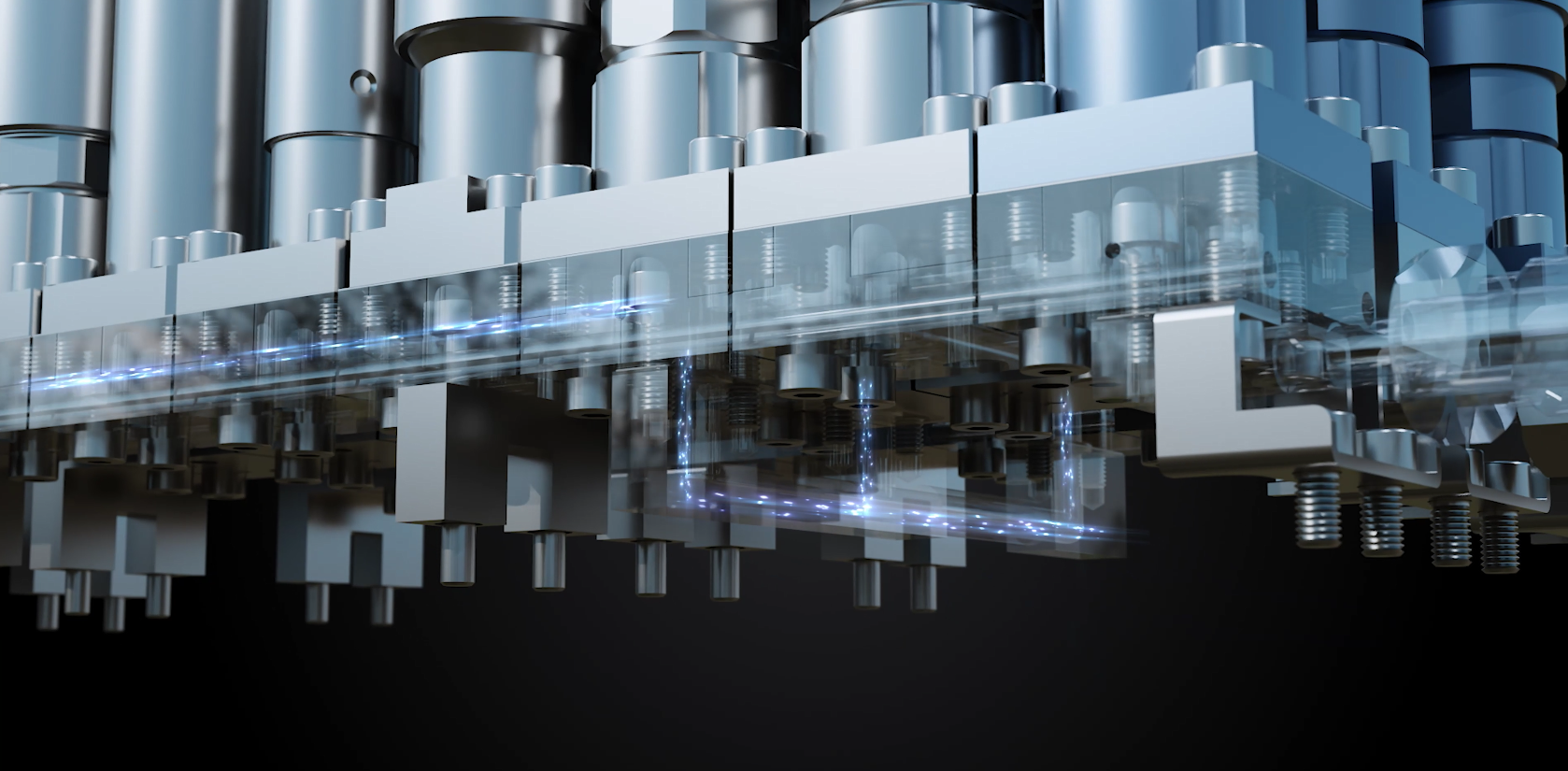

Solve the multiple gases,complicated-multiple airways and flow channel manufacture

Precision Electron Beam Welding, Aluminum Alloy Brazing, and Laser Welding are high-efficiency methods offering high welding fusion rate and deep penetration. These methods ensure suitability for products with multi-layer structures and complex flow channels, such as water and gas channels, guaranteeing industry-leading precision, reliability, and performance.

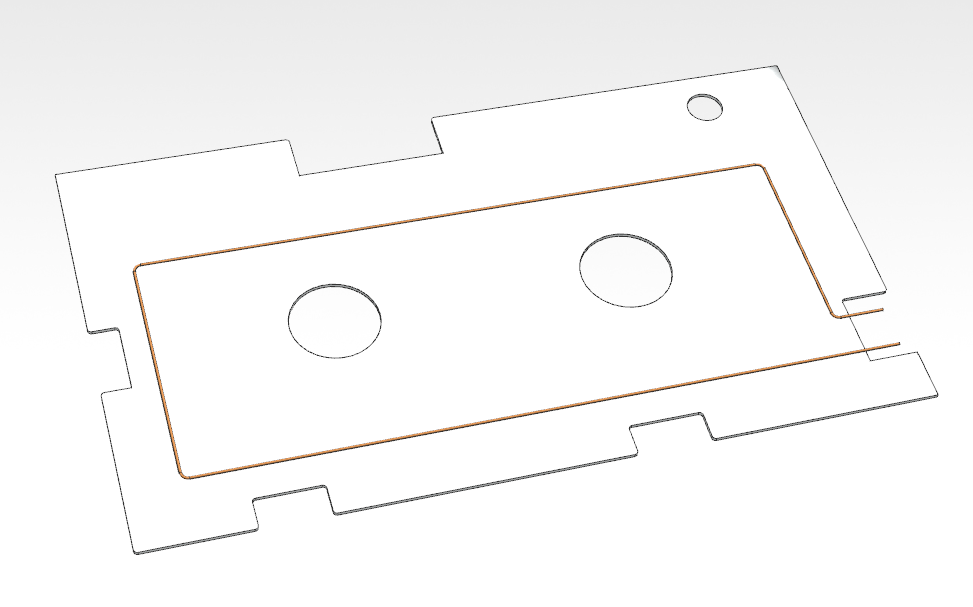

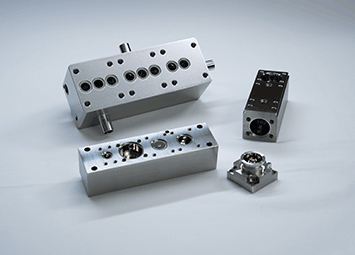

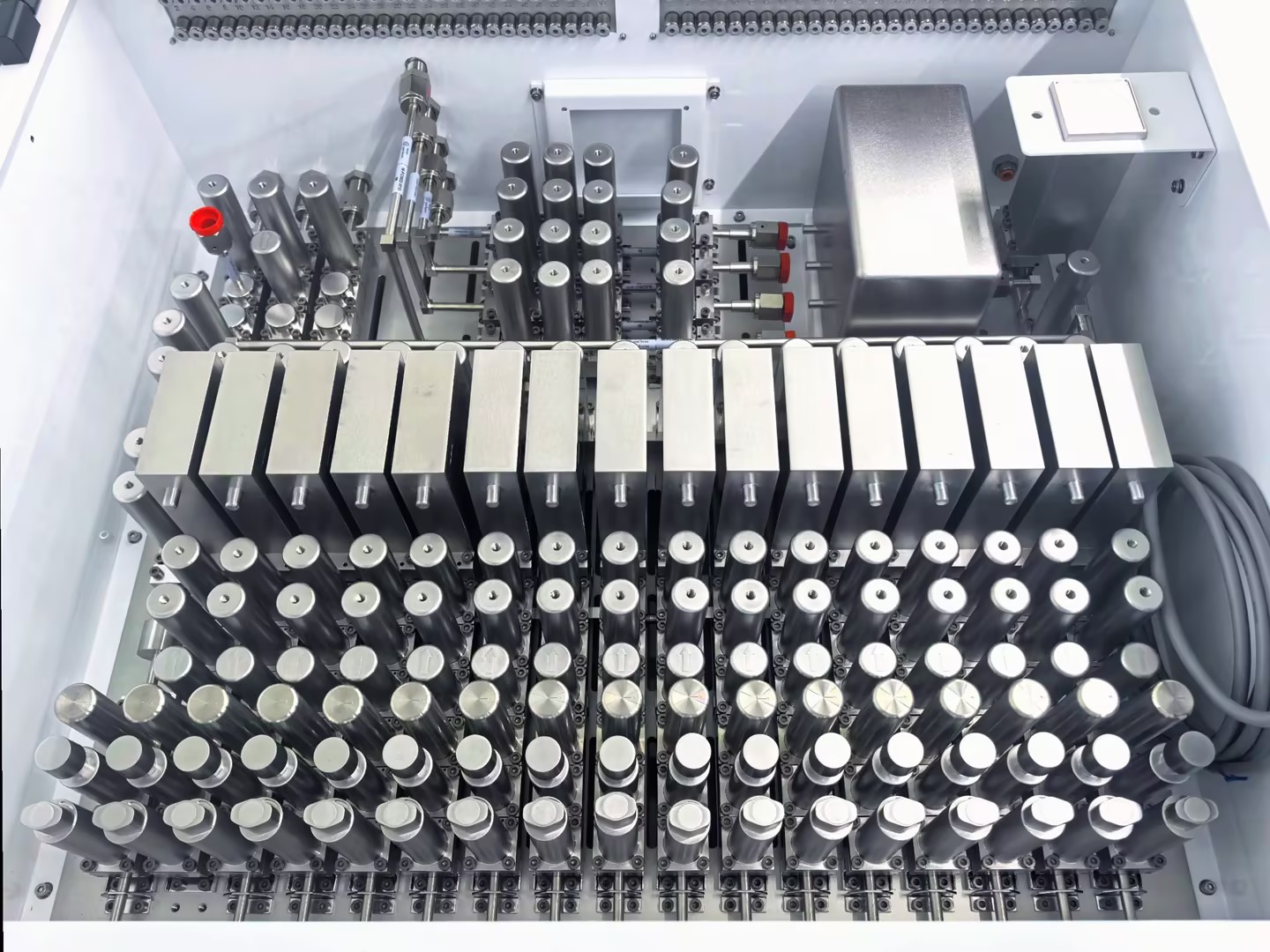

Solve showerhead cleanliness

Precision cleaning and nanoscale coating technologies ensure controllable metal element contamination and particle contamination, addressing product cleanliness and process gas cleanliness issues.

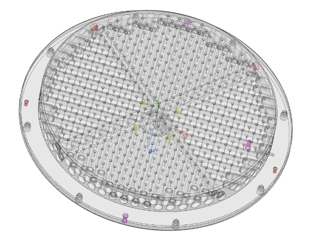

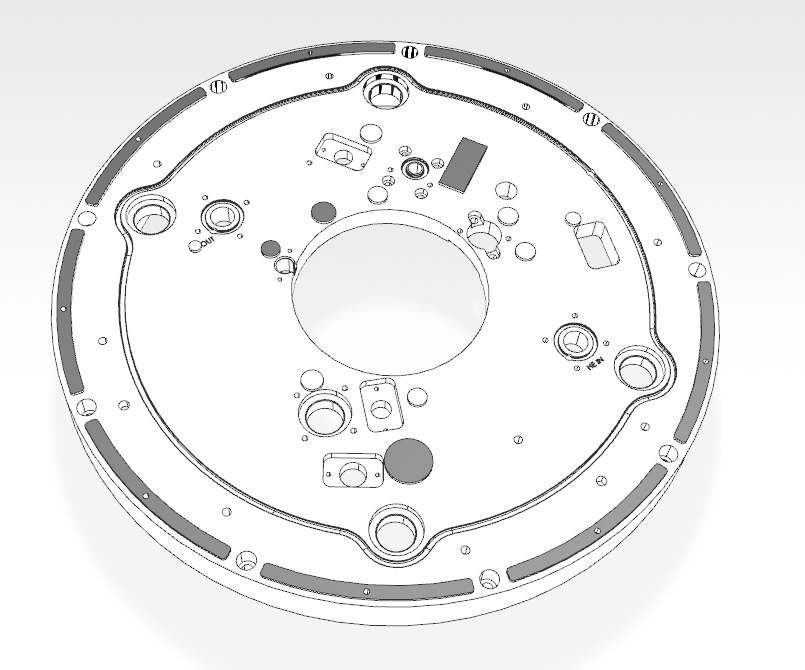

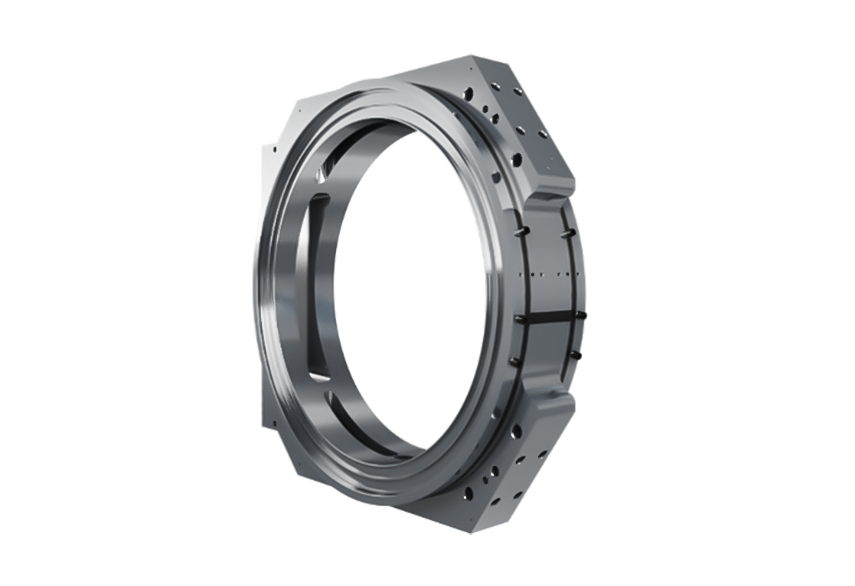

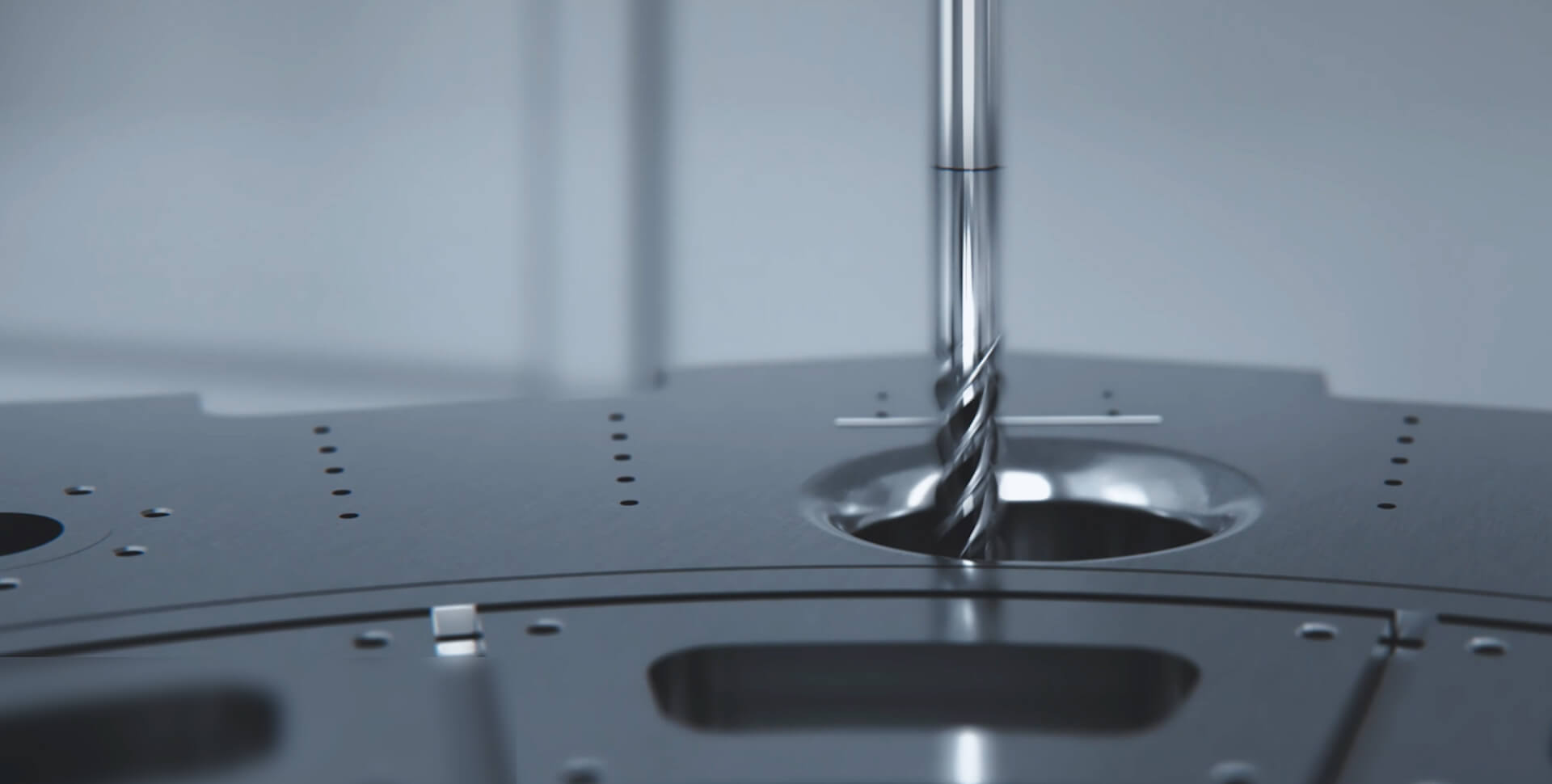

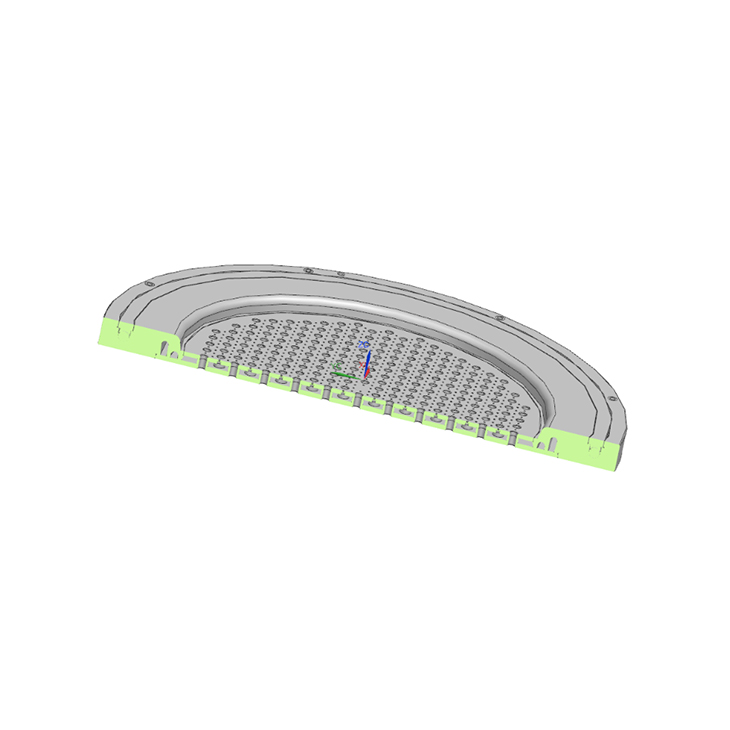

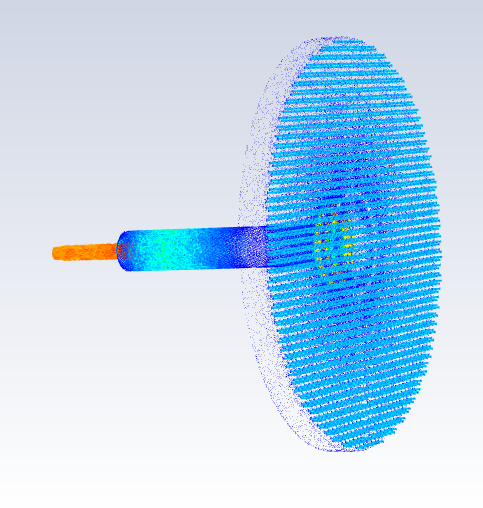

Solve small hole structure design and distribution

CAE-assisted design technology is employed for coupled simulations (flow field, thermal field, etc.) to optimize micro-hole design and distribution, ensuring uniform product coating.

Solve Process Coating Uniformity Issues

A multifaceted approach, encompassing efficient machining solution design, precision manufacturing methods (including 5-axis, 3-axis, lathe, and mill-turn composite machining), and AOI inspection equipment, ensures consistent hole diameter and guarantees coating uniformity in the wafer.