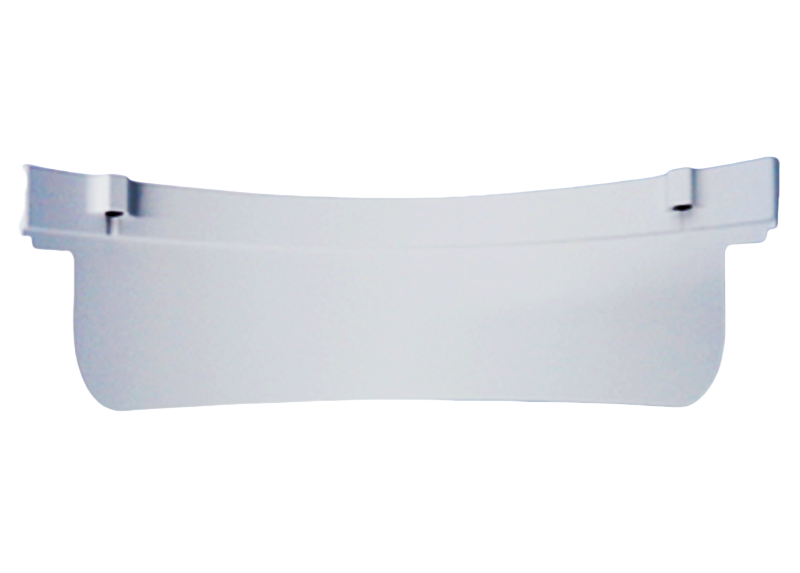

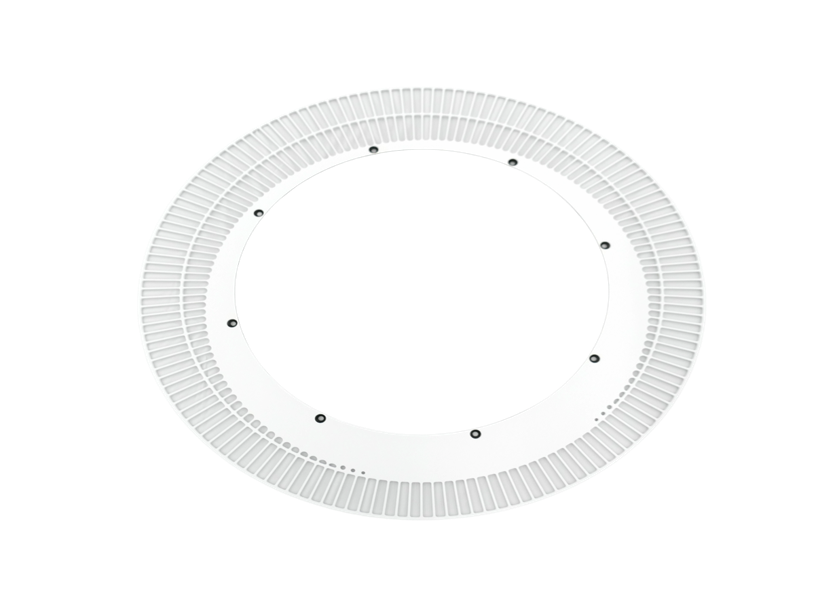

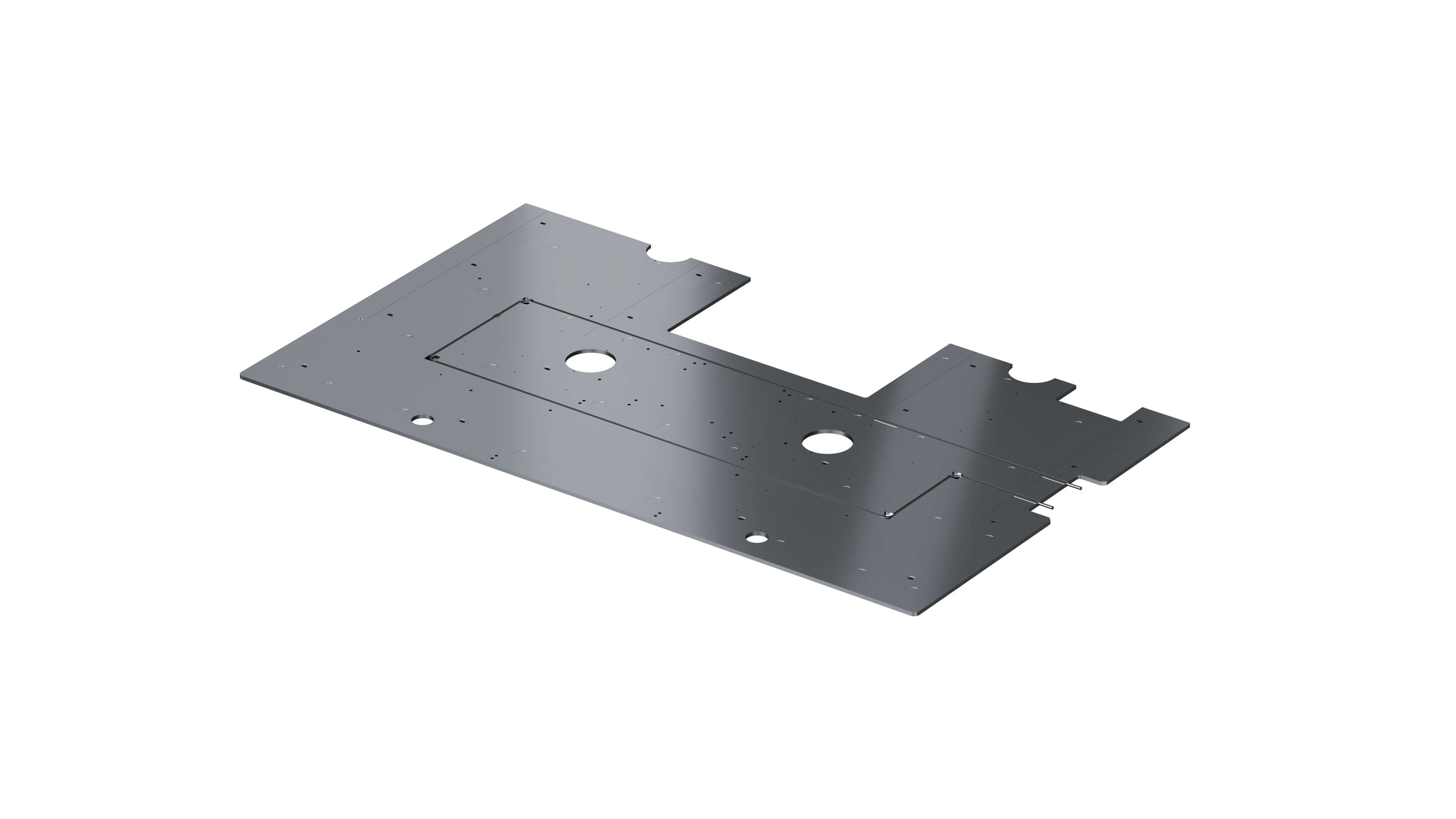

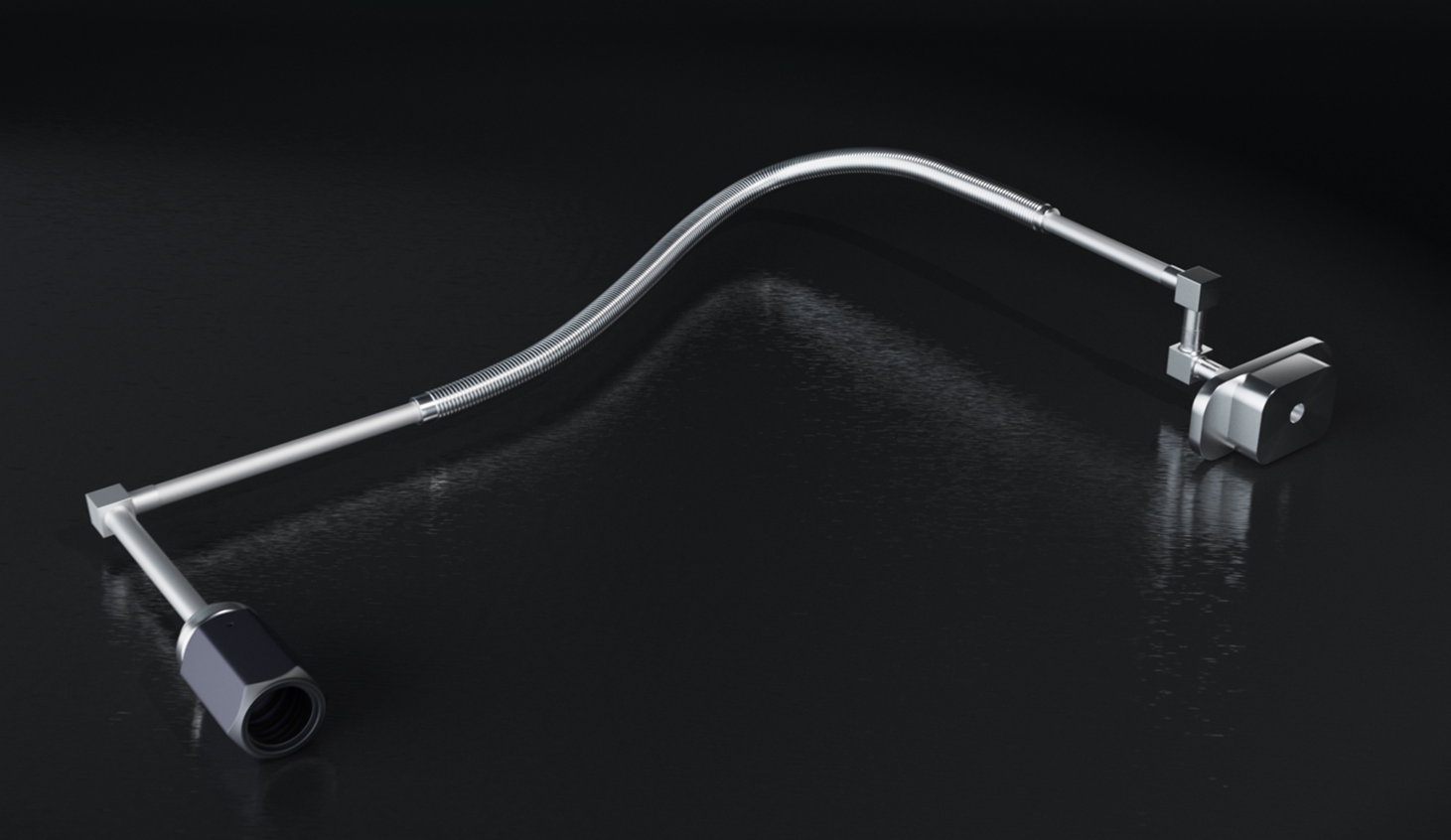

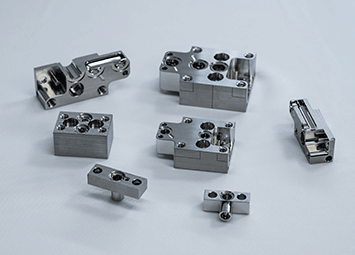

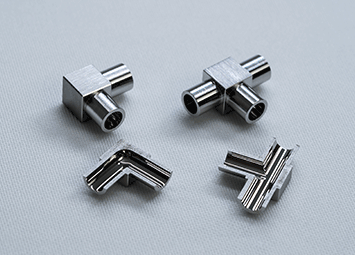

Customized Product Design

Meeting needs for custom interfaces, dimensions, surface treatments, etc.

Our rapid-response design team addresses customer needs, ensuring application requirements arising from installation compatibility, process characteristics, and other factors are met.

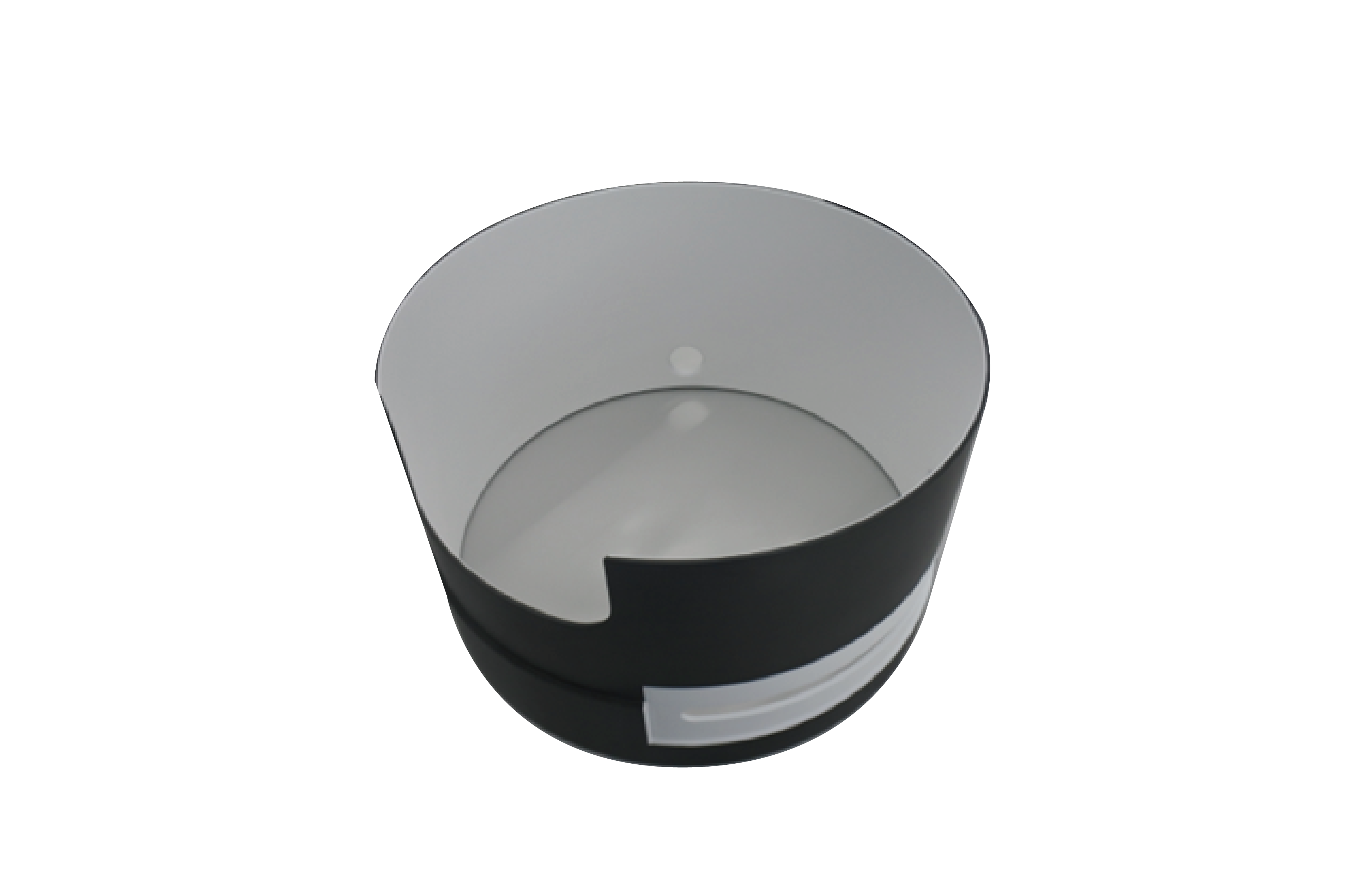

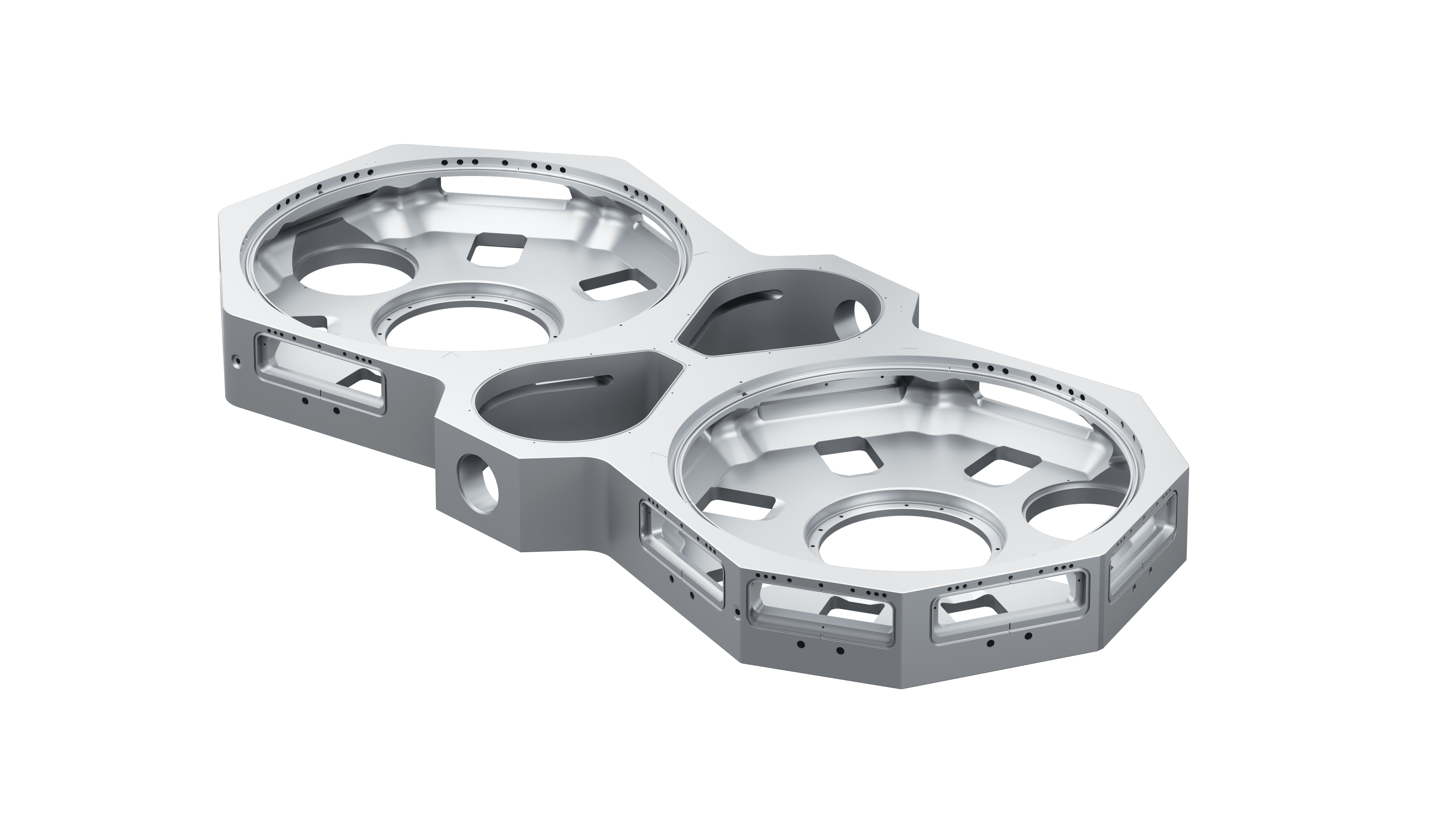

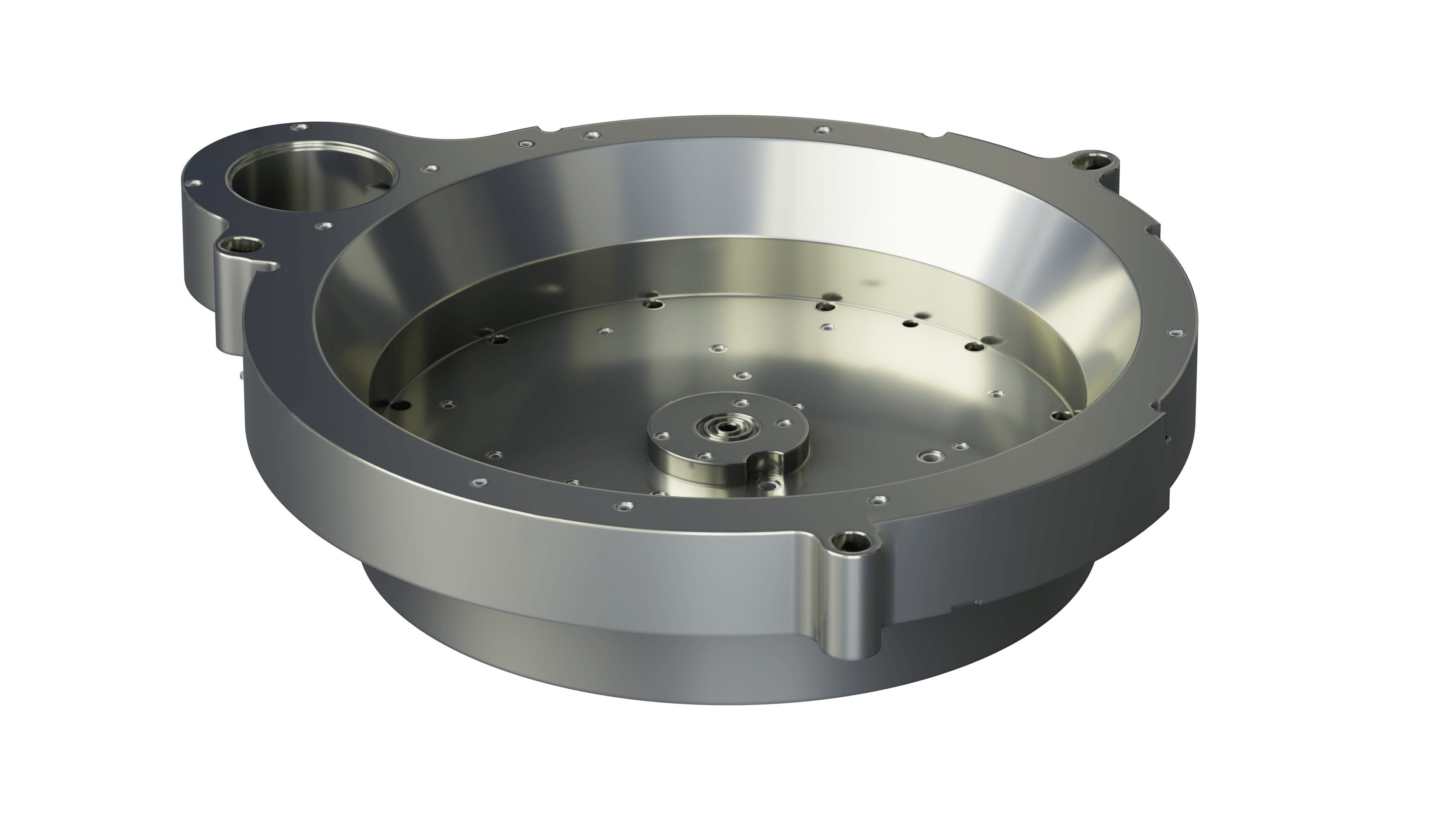

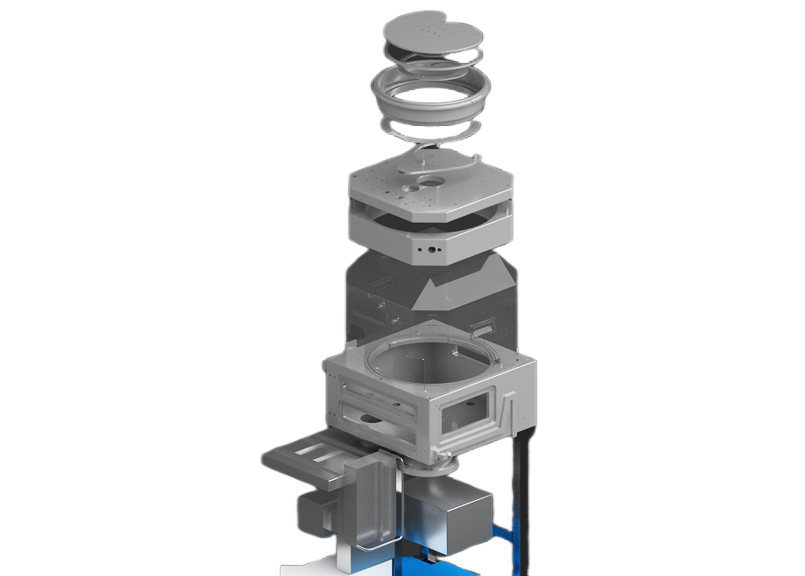

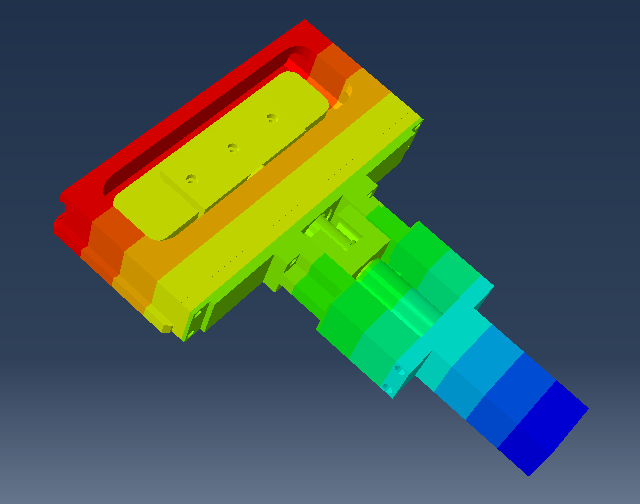

Mechanical Design and Simulation Analysis

Providing vibration analysis and particle generation/contamination analysis solutions.

Precision structural design and Finite Element Analysis (FEA) simulation are used to identify and quantify friction, impact, and contact points, enabling control and optimization of vibration and contaminant particle generation.

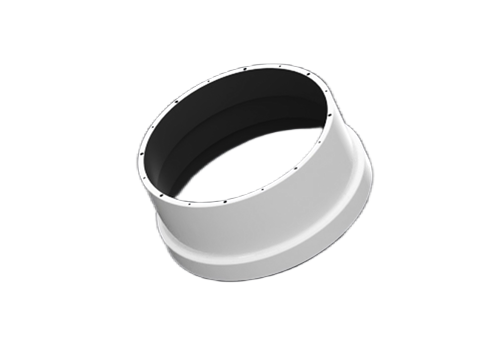

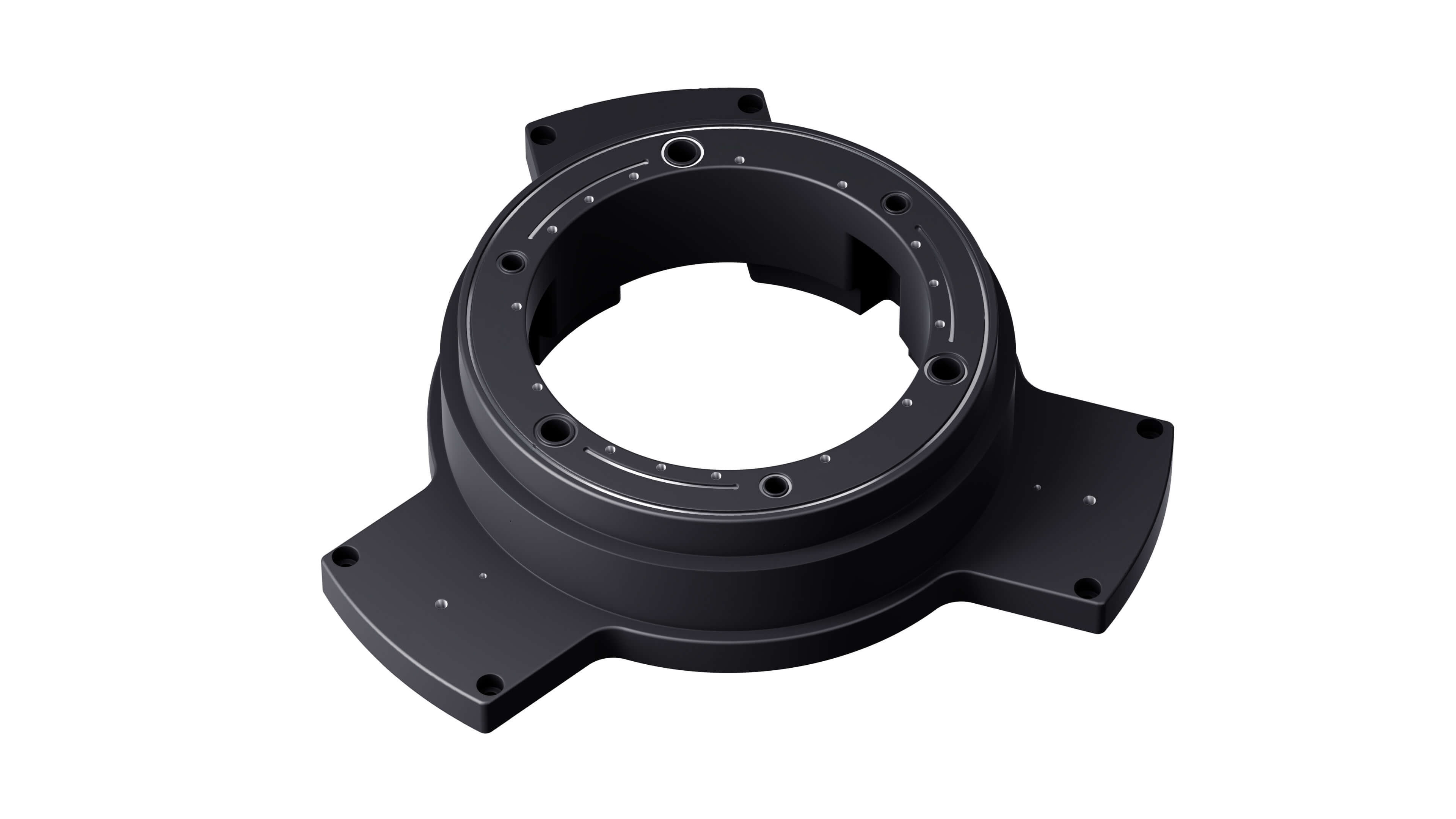

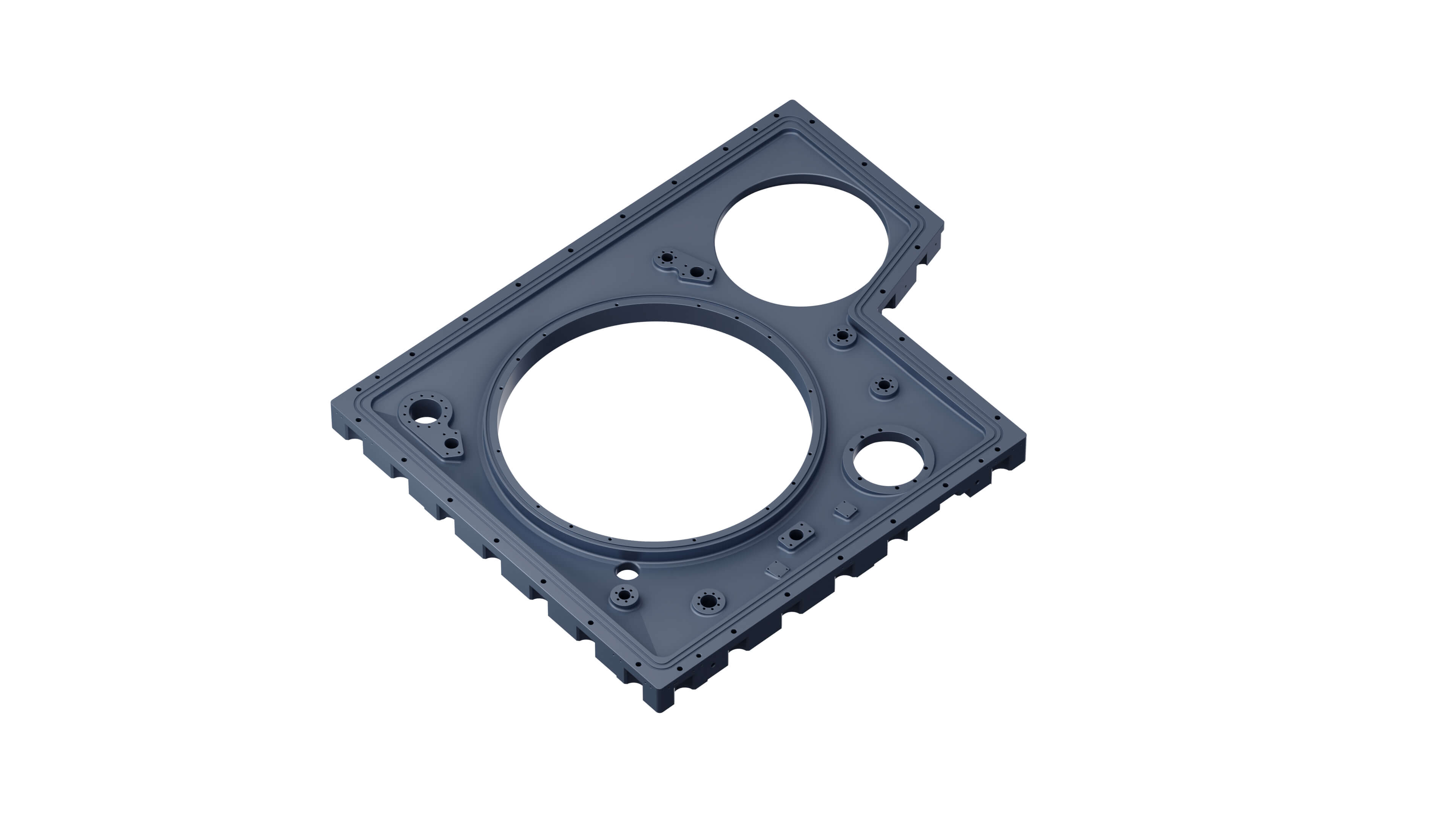

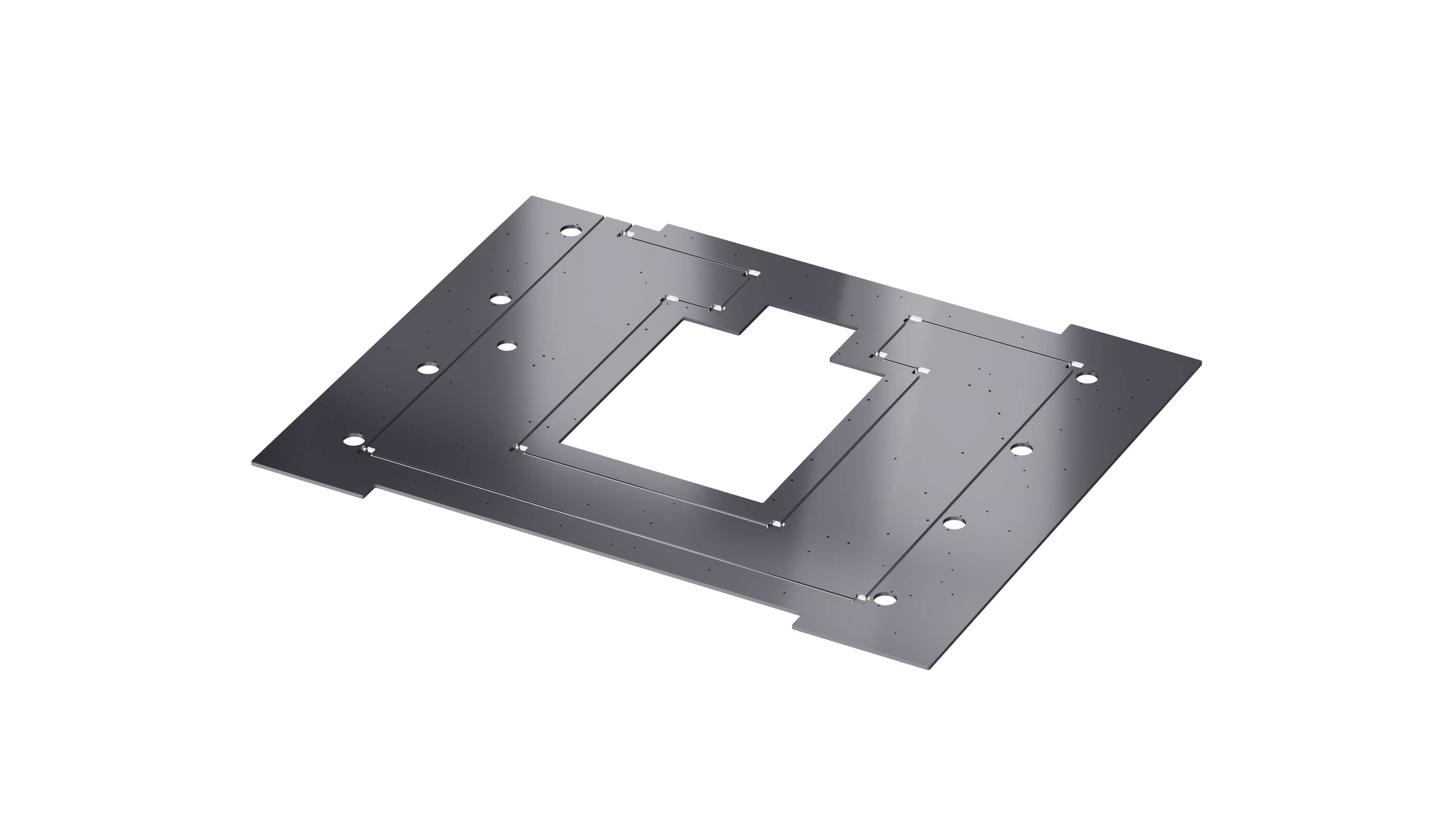

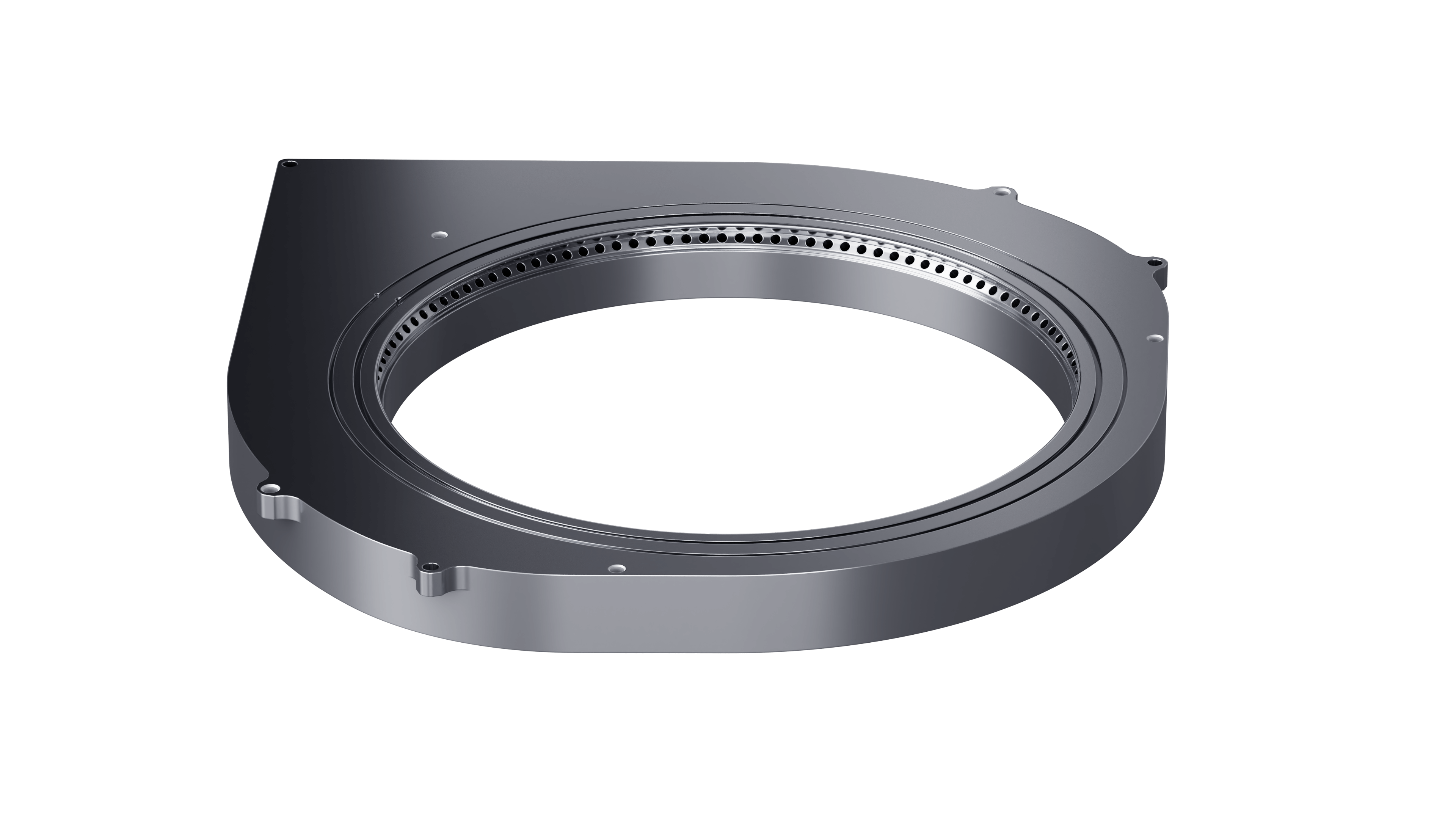

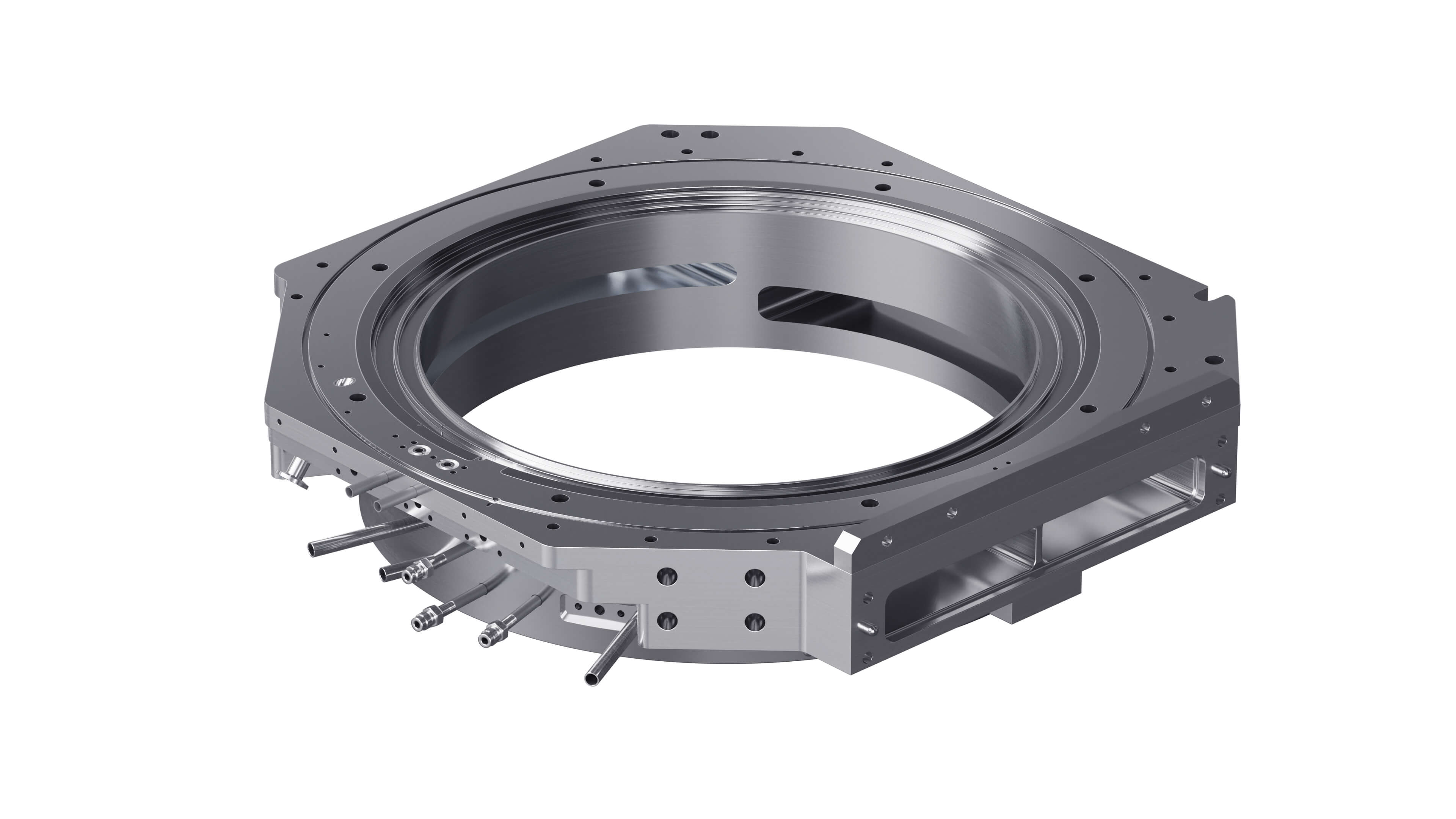

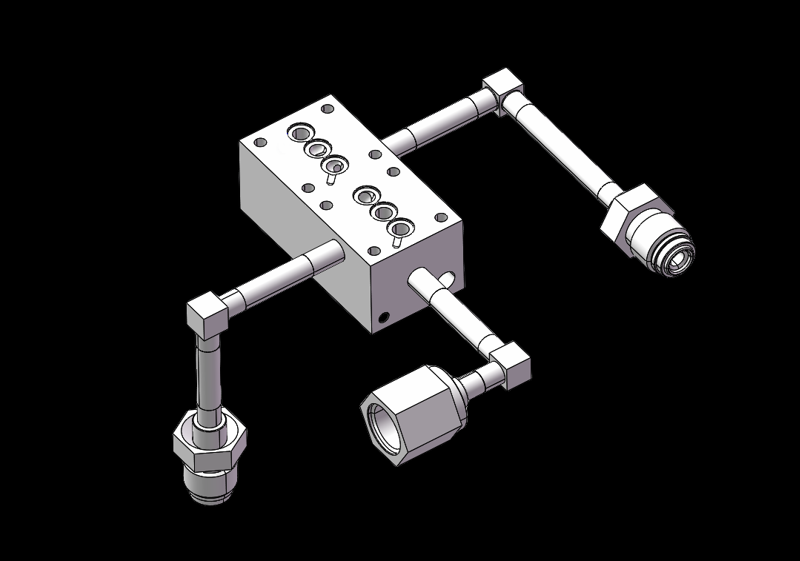

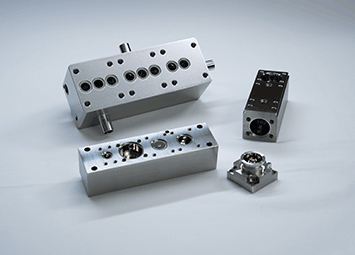

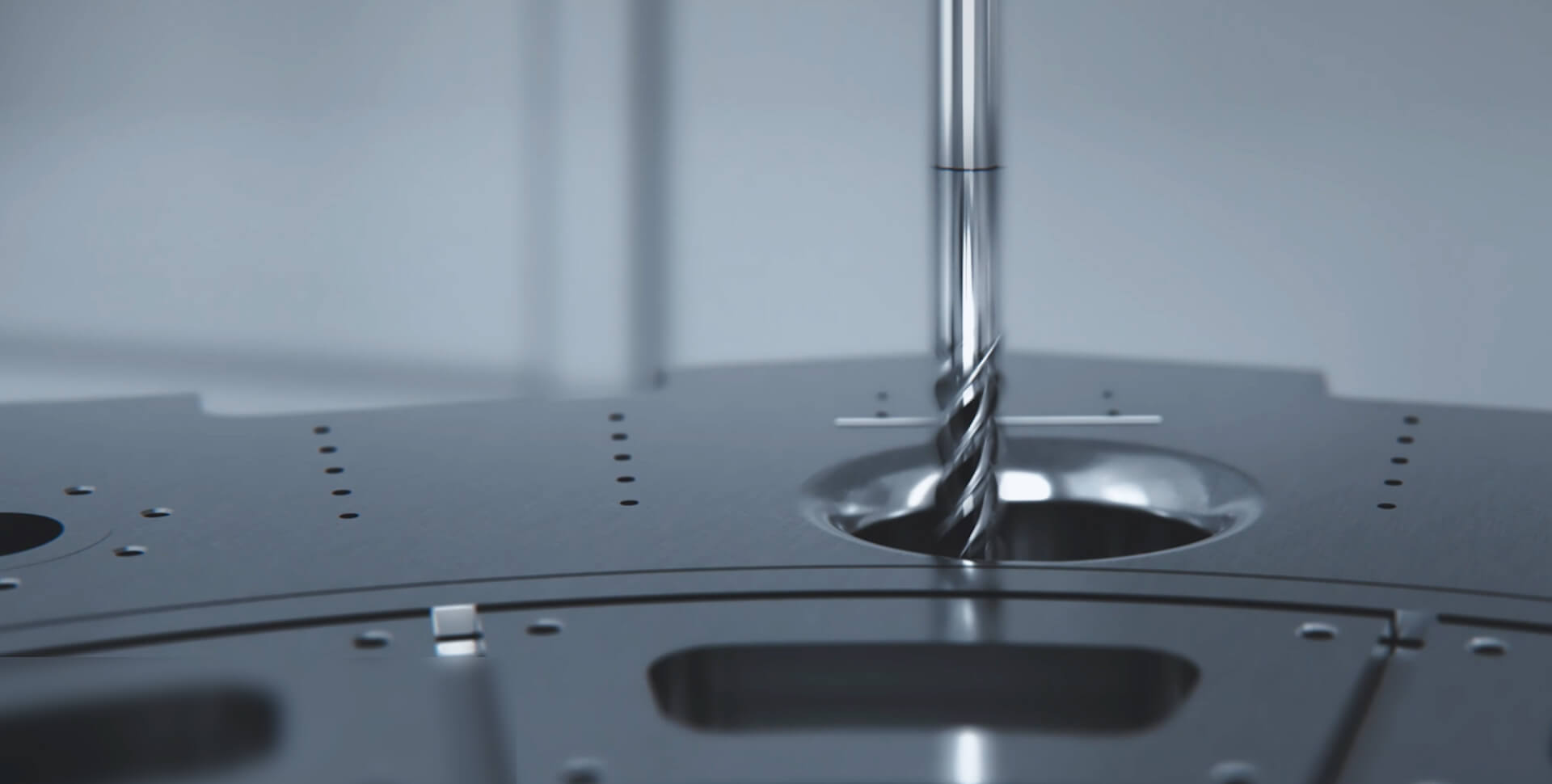

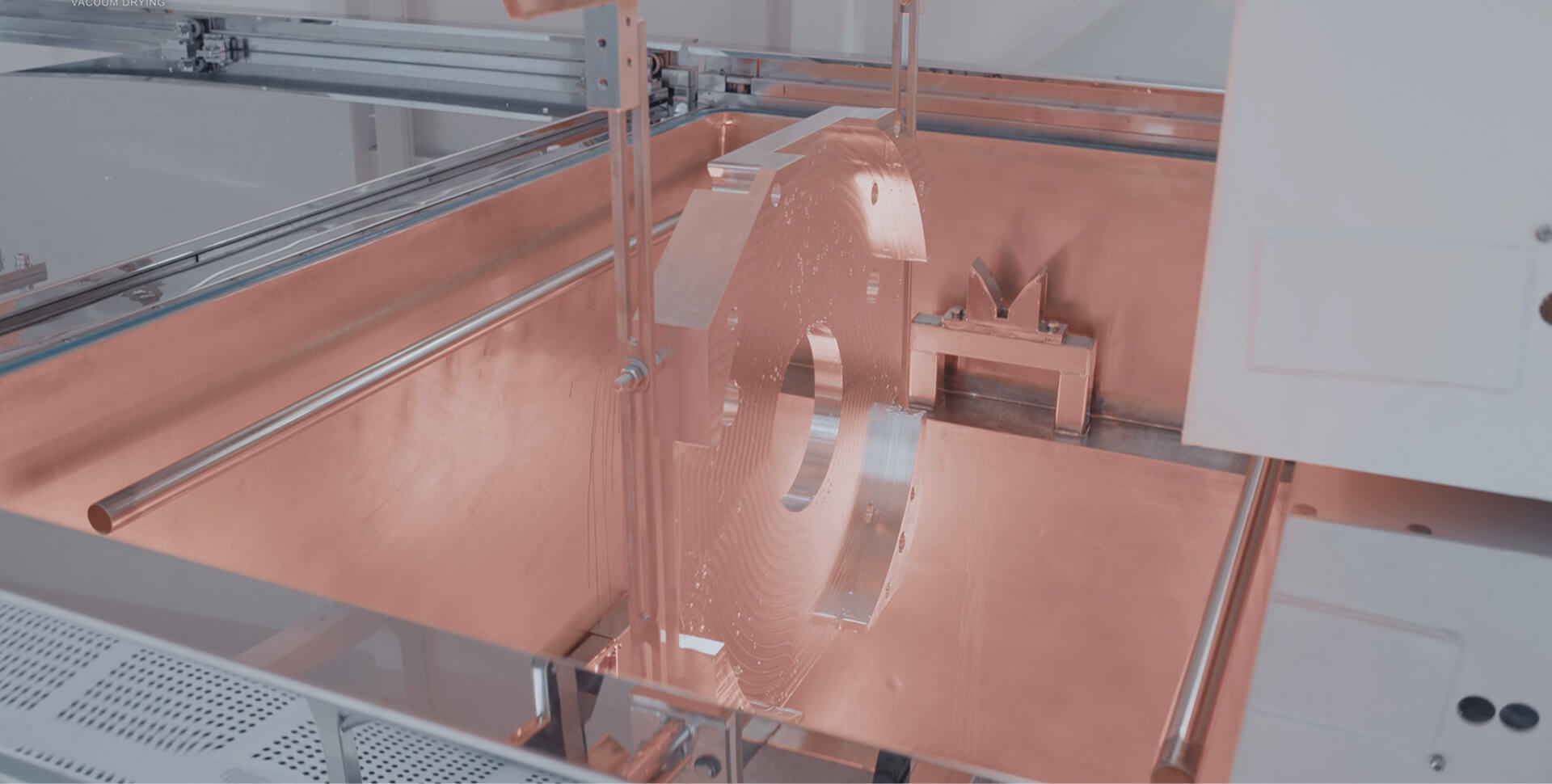

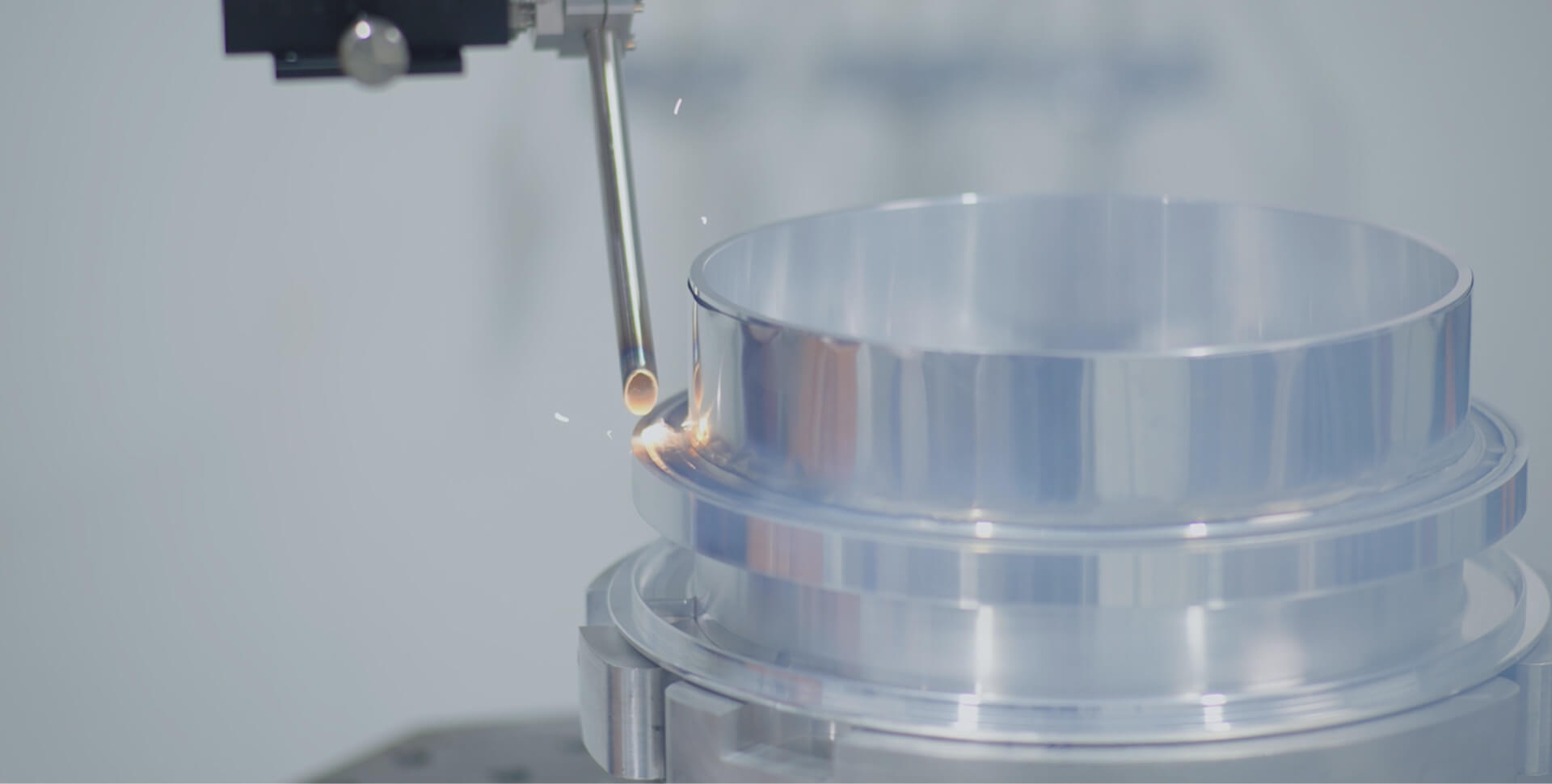

Precision Manufacturing and Assembly

Addressing part machining quality and product assembly consistency issues.

Our manufacturing processes are characterized by efficient machining solution design, precision manufacturing methods (including 5-axis, 3-axis, and mill-turn composite machining), assembly within Class 1000 and Class 100 cleanroom environments, and rigorous workstation-level process control.

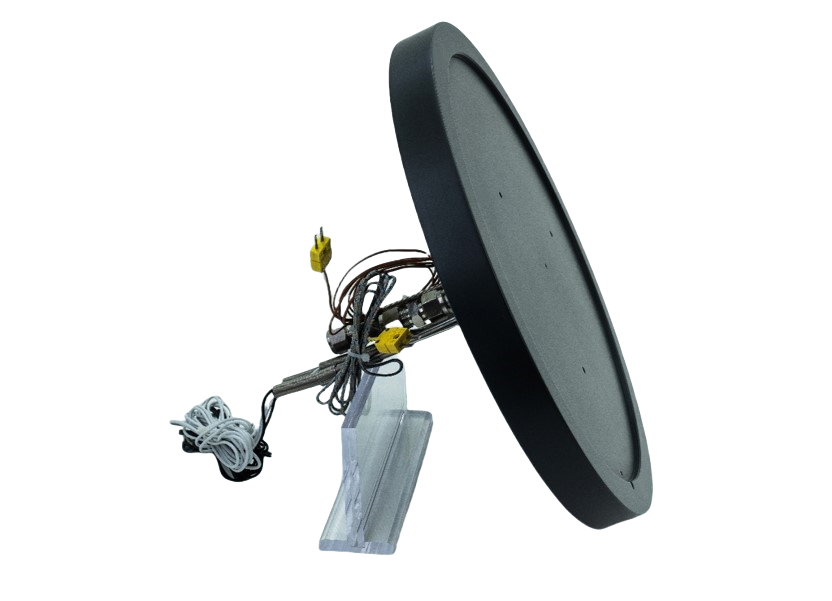

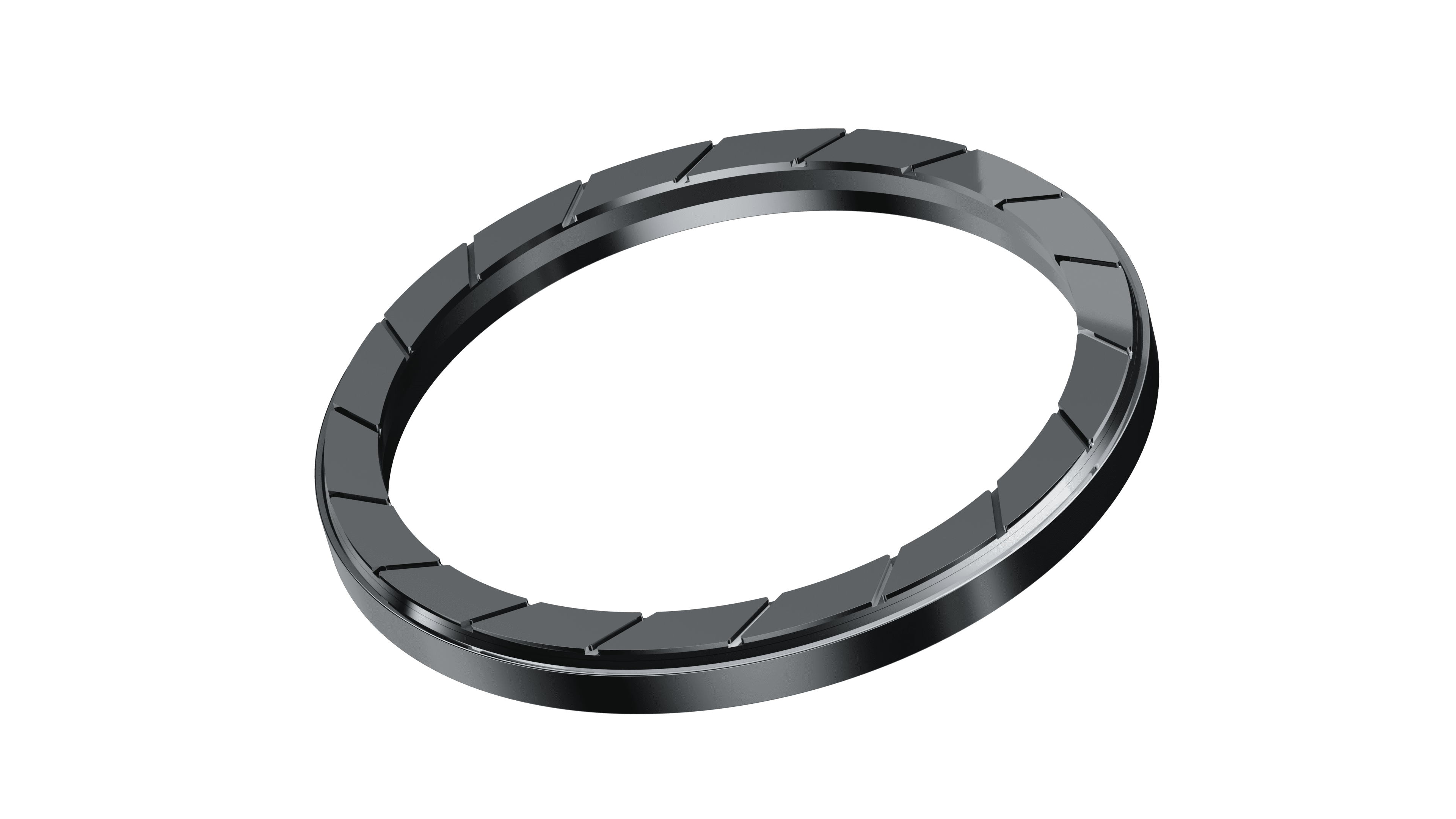

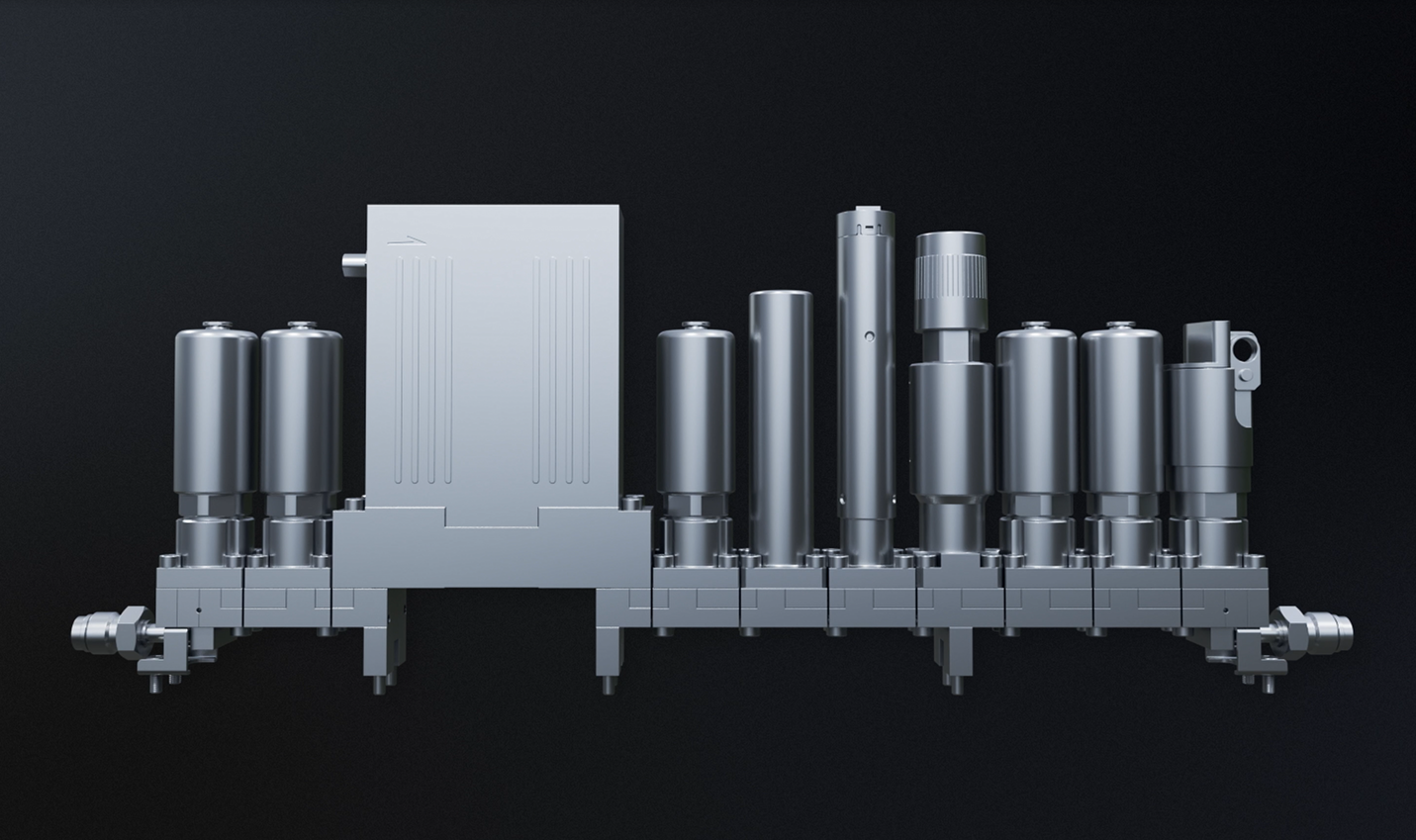

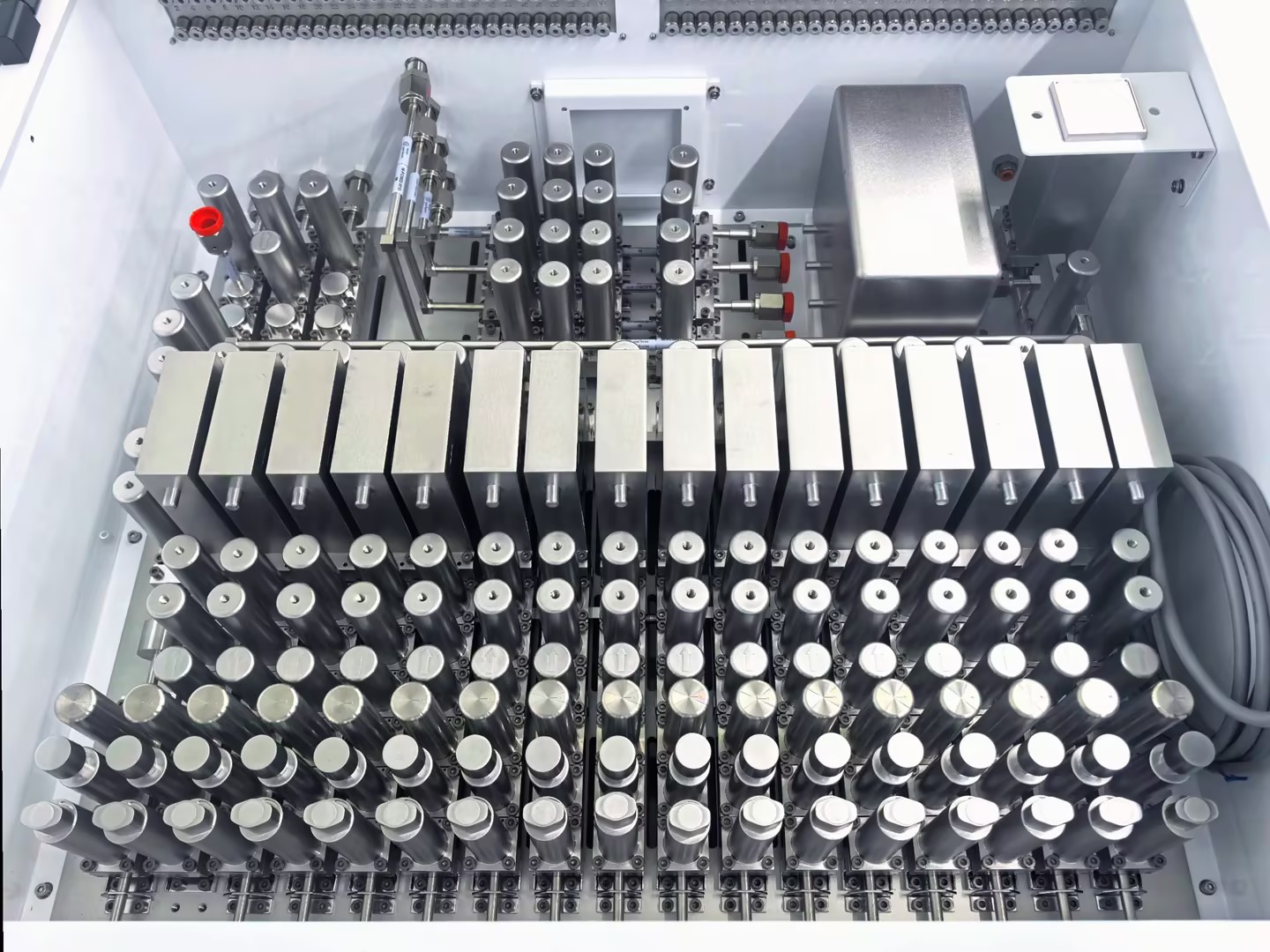

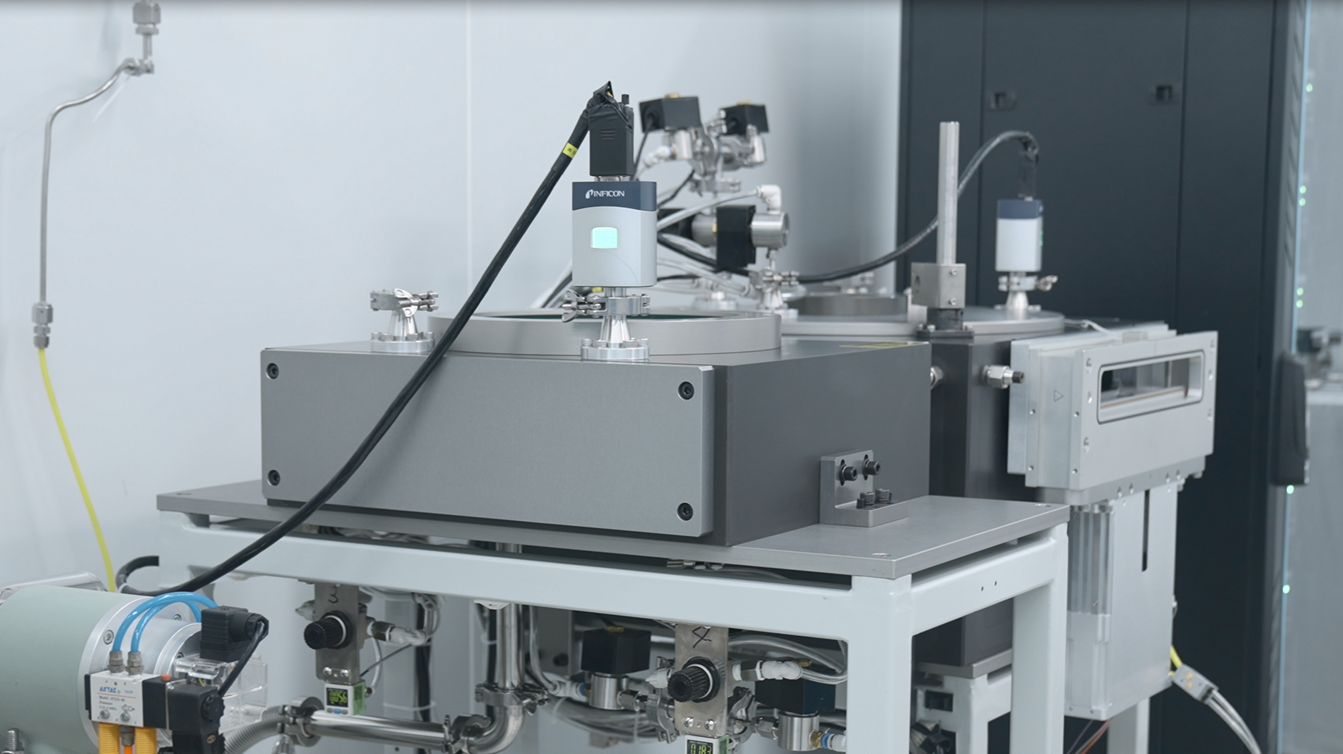

Testing and Validation

Addressing product performance testing and reliability Verification Issue.

We utilize a multi-functional vacuum testing platform designed to closely replicate client-side operating conditions. This platform features integrated control and operation software, enabling synchronous testing of multiple product types and quantities, and providing comprehensive measurement of key performance parameters, such as pressure difference, vibration, particle levels, and temperature resistance.